1 Supplementary Operating Manual

4 of 12

Double Mechanical Seals

1 Supplementary Operating Manual

1.1 General

This supplementary operating manual accompanies the installation/operating

manual. All information contained in the installation/operating manual must be

observed.

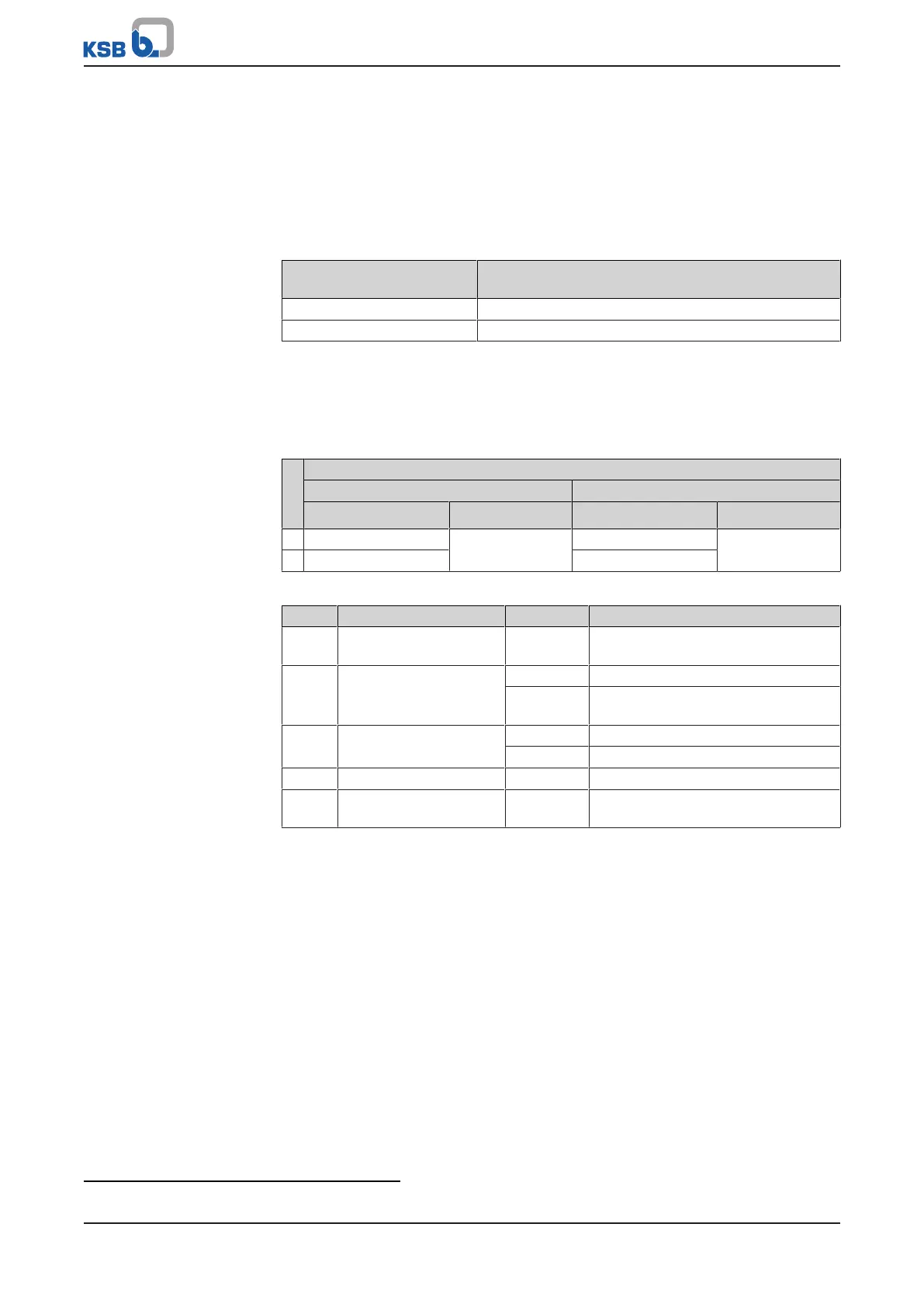

Table1: Relevant operating manuals

Type series Reference number of the installation/operating

manual

Etaprime L 2753.81

Etaprime B 2753.82

1.2 Technical data

Design details

The shaft is sealed by 2 unbalanced single bi-directional mechanical seals to EN12756

in back-to-back arrangement, with barrier fluid system.

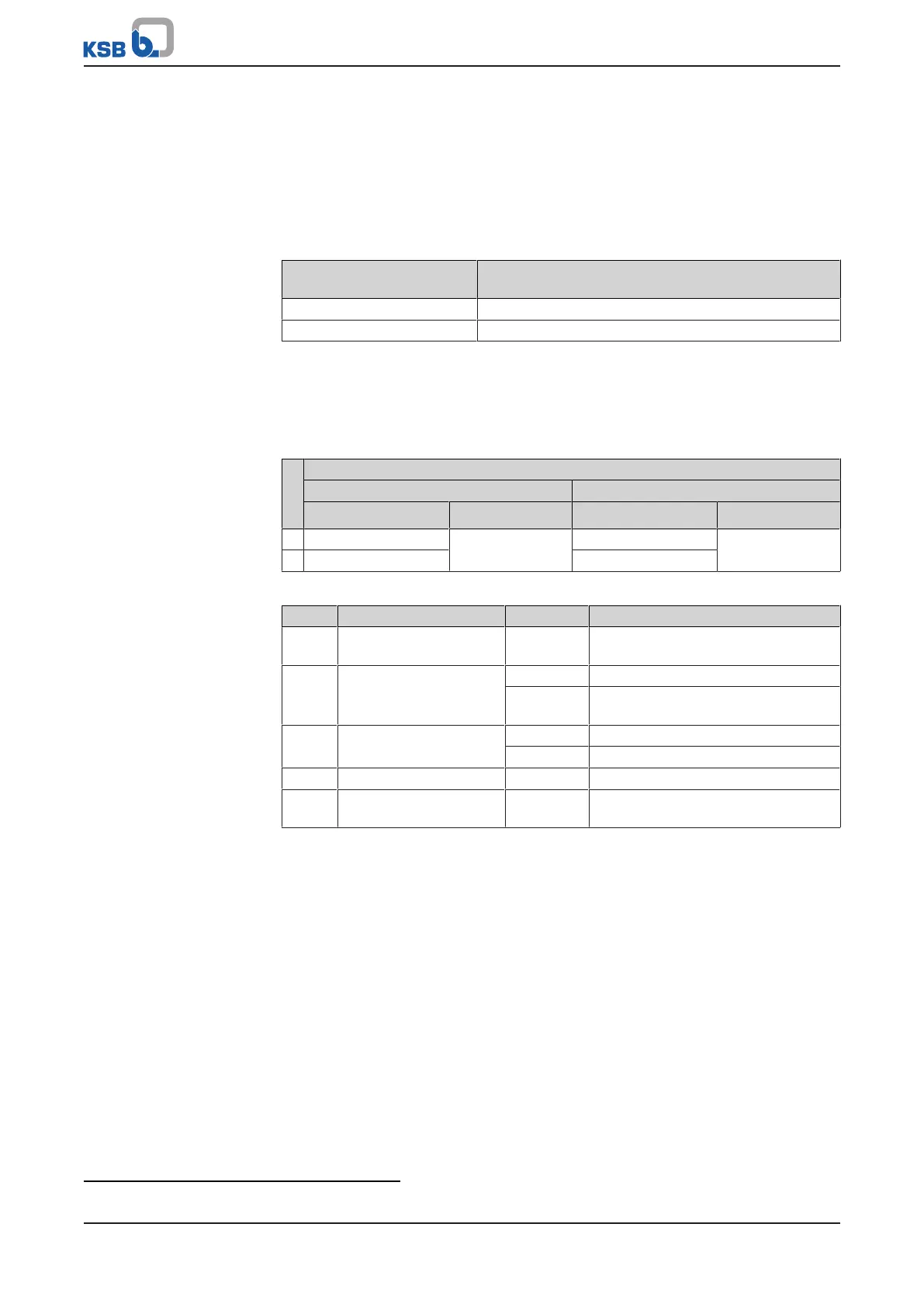

Seal size/ material variant

Table2: Material variant

Shaft unit

Mechanical seal

Outboard (433.02) Inboard (433.01)

Seal size Material variant

1)

Seal size Material variant

25 KU028S-M7-N Q1BVGG KU028S-M7-G49 Q1Q1K9GG-G

35 KU038S-M7-N KU038S-M7-G49

Material code

Table3: Material code

Item Description Code Materials

1 Primary ring Q1 SiC, silicon carbide, sintered without

pressure

2 Mating ring B Resin-impregnated hard carbon

Q1 SiC, silicon carbide, sintered without

pressure

3 Secondary seal V Fluoroelastomer (Viton)

K9 Perfluoroelastomer

4 Spring G CrNiMo steel

5 Other

components

G CrNiMo steel

1.3 Removing the shaft seal

1.3.1 Removing the shaft seal - shaft units 25/35

ü Dismantle the pump as described in operating manual 2753.81 or 2753.82.

ü The back pull-out unit has been placed in a clean and level assembly area.

1. Take hexagon nut 920.95, disc 550.95 (shaft unit 25 only), safety device 930.95,

impeller 230 and discs 550.02/.04 off shaft 210.

2. Take key 940.01 out of the shaft keyway.

3. Take spacer sleeve 525 (shaft unit 35 only) off shaft 210.

4. Remove fitting 720.13/.14 and joint ring 411.13/.14.

5. Undo hexagon nut 920.02 at seal cover 471. Abut the seal cover against the

bearing bracket or motor, as applicable.

1) For units with closed thermosyphon system: material variant Q1Q1K9GG

Loading...

Loading...