ENGINE

B2650HSDC, B3350HSDC, WSM

1-S60

(Continued)

(Reference)

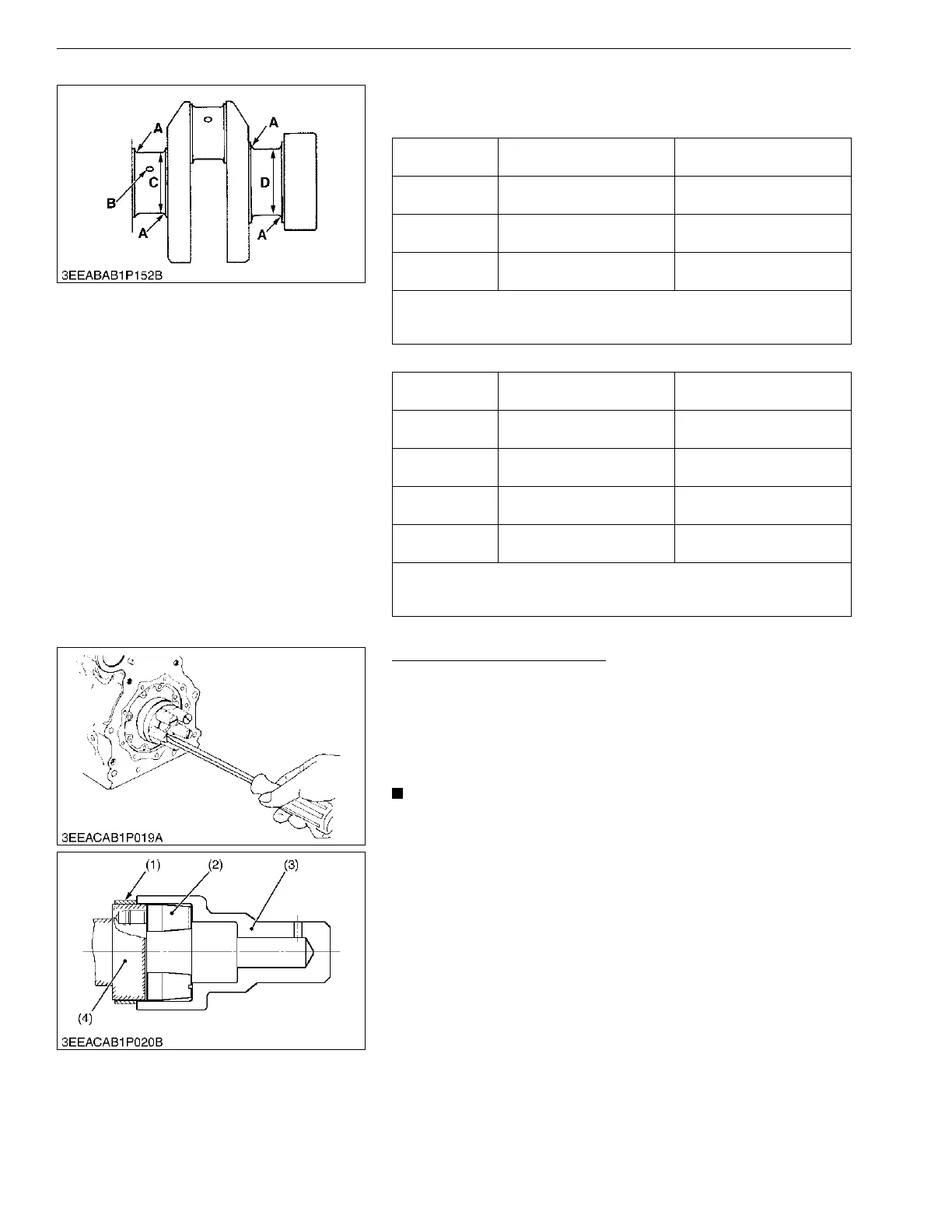

• Undersize dimensions of crankshaft journal

[D1305-E4]

[V1505-T-E4]

9Y1210822ENS0111US0

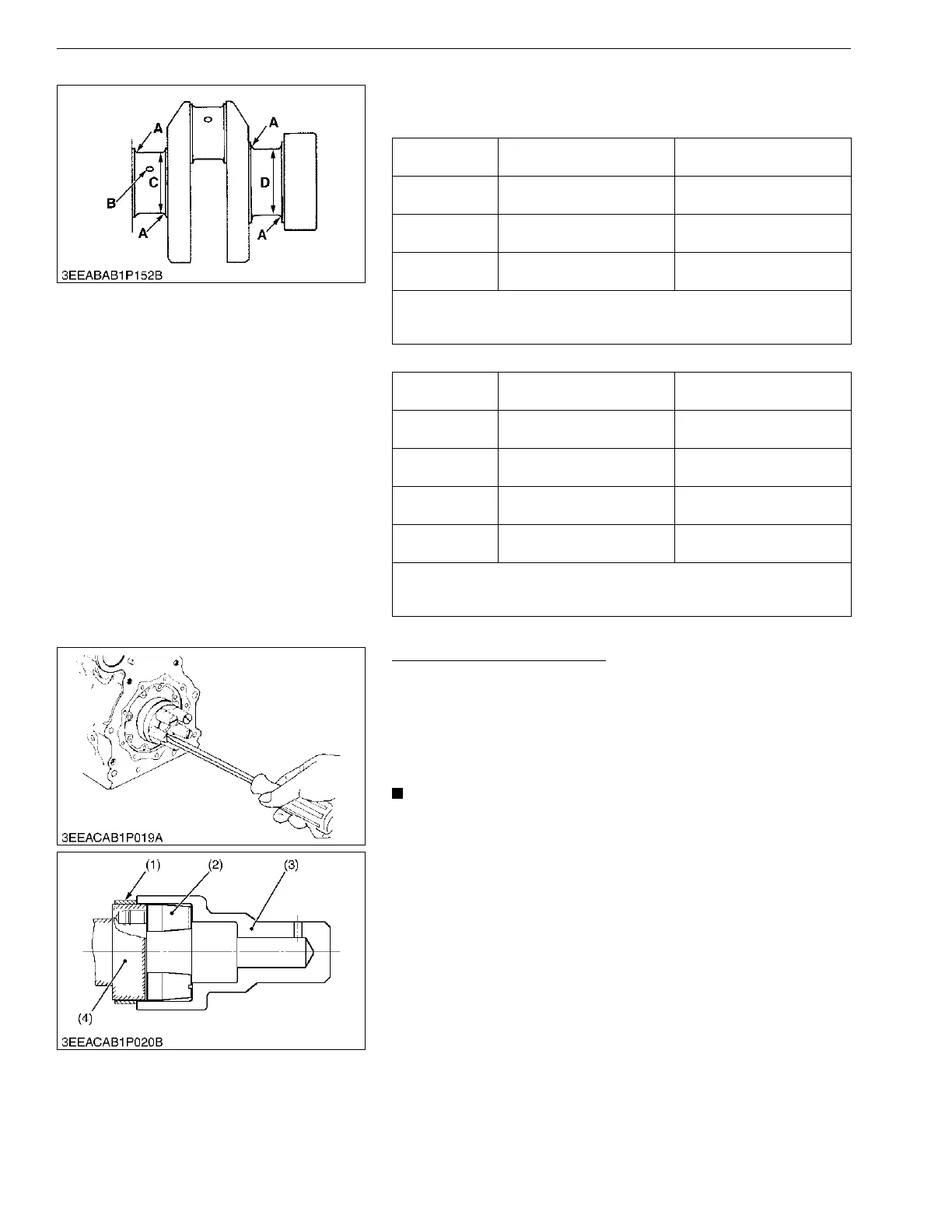

Replacing Crankshaft Sleeve

1. Remove the used crankshaft sleeve.

2. Set the sleeve guide (2) to the crankshaft.

3. Heat a new sleeve to a temperature between 150 and 200 °C

(302 and 392 °F), and fix the sleeve to the crankshaft as shown

in figure.

4. Press fit the sleeve using the auxiliary socket for pushing (3).

• Mount the sleeve with its largely chamfered surface facing

outward.

• Should heating is not enough, a sleeve might stop halfway,

so careful.

9Y1210822ENS0112US0

Undersize

0.20 mm

0.0079 in.

0.40 mm

0.016 in.

Dimension A

2.3 to 2.7 mm radius

0.091 to 0.10 in. radius

2.3 to 2.7 mm radius

0.091 to 0.10 in. radius

*Dimension B

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

Dimension C

51.721 to 51.740 mm dia.

2.0363 to 2.0370 in. dia.

51.521 to 51.540 mm dia.

2.0284 to 2.0291 in. dia.

The crankshaft must be fine-finished to higher than Rmax = 0.8S

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.040 to 0.059 in.) relief.

Undersize

0.20 mm

0.0079 in.

0.40 mm

0.016 in.

Dimension A

2.3 to 2.7 mm radius

0.091 to 0.10 in. radius

2.3 to 2.7 mm radius

0.091 to 0.10 in. radius

*Dimension B

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

Dimension C

47.734 to 47.750 mm dia.

1.8793 to 1.8799 in. dia.

47.534 to 47.550 mm dia.

1.8715 to 1.8720 in. dia.

Dimension D

51.721 to 51.740 mm dia.

2.0362 to 2.0370 in. dia.

51.521 to 51.540 mm dia.

2.0284 to 2.0291 in. dia.

The crankshaft must be fine-finished to higher than Rmax = 0.8S

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.040 to 0.059 in.) relief.

(1) Crankshaft Sleeve

(2) Sleeve Guide

(3) Auxiliary Socket for Pushing

(4) Crankshaft

Loading...

Loading...