S-70

SM-E2B SERIES, WSM

DIESEL ENGINE

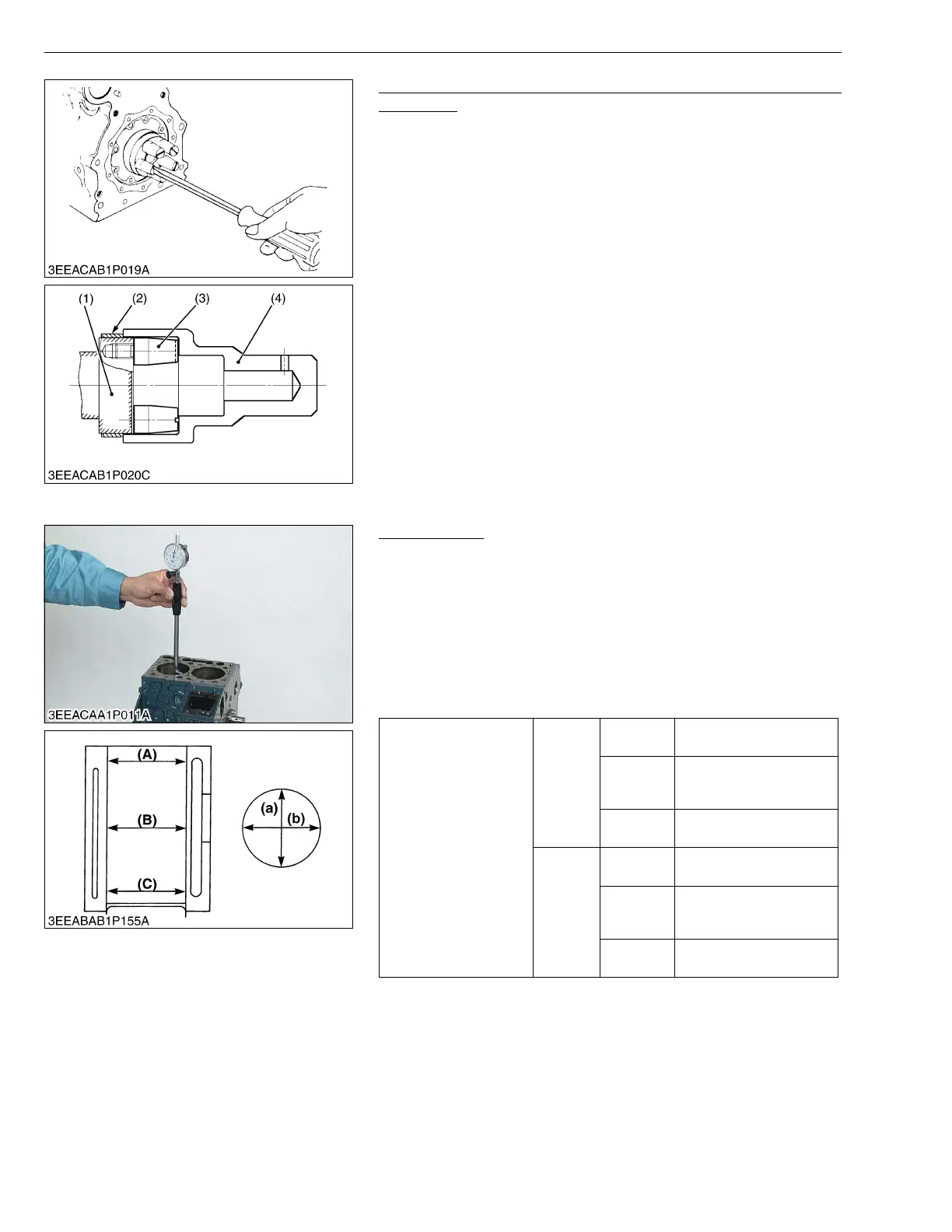

Replacing Crankshaft Sleeve (Z482-E2B, D662-E2B, D722-E2B,

D782-E2B)

1. Remove the used crankshaft sleeve (2).

2. Set the sleeve guide (3) to the crankshaft (1).

3. Heat a new sleeve to a temperature between 150 and 200 °C

(302 and 392 °F), and fix the sleeve to the crankshaft as shown

in figure.

4. Press fit the sleeve using the auxiliary socket for pushing (4).

(Refer to “SPECIAL TOOLS”.)

• Mount the sleeve with its largely chamfered surface facing

outward.

• Should heating is not enough, a sleeve might stop halfway,

so careful.

W1048540

(5) Cylinder

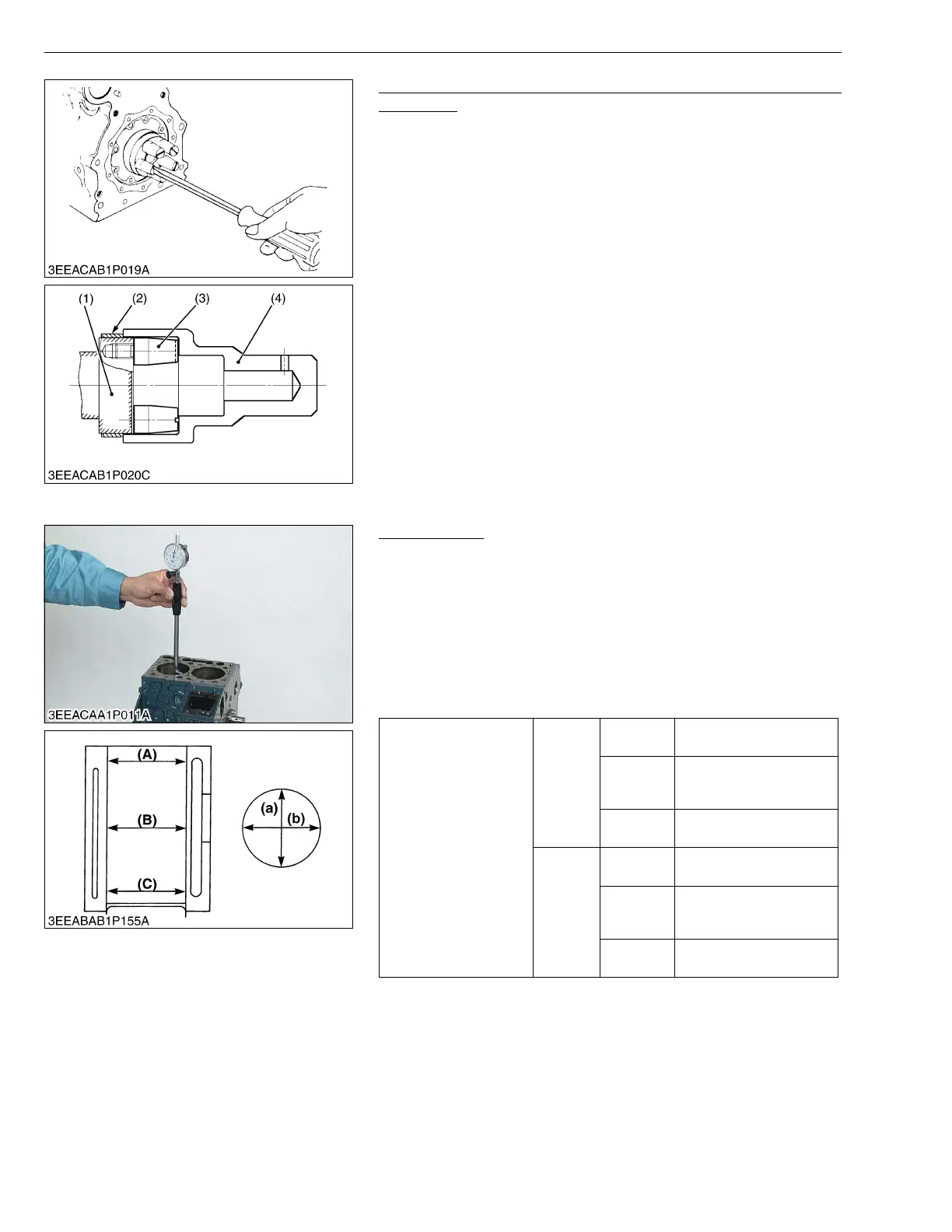

Cylinder Wear

1. Measure the cylinder liner I.D. at the six positions (see figure)

with a cylinder gauge to find the maximum and minimum I.D.’s.

2. Get the difference (Maximum wear) between the maximum and

the minimum I.D.’s.

3. If the wear exceeds the allowable limit, bore and hone to the

oversize dimension. (Refer to “Correcting Cylinder”.)

4. Visually check the cylinder wall for scratches. If deep scratches

are found, the cylinder should be bored. (Refer to “Correcting

Cylinder”.)

W10360060

(1) Crankshaft

(2) Crankshaft Sleeve

(3) Sleeve Guide

(4) Auxiliary Socket for Pushing

Cylinder liner I.D.

Factory

spec.

D662-E2B

64.000 to 64.019 mm

2.51968 to 2.52043 in.

Z482-E2B

D722-E2B

D782-E2B

67.000 to 67.019 mm

2.63779 to 2.63854 in.

Z602-E2B

D902-E2B

72.000 to 72.019 mm

2.83464 to 2.83539 in.

Allowable

limit

D662-E2B

64.150 mm

2.52559 in.

Z482-E2B

D722-E2B

D782-E2B

67.150 mm

2.64370 in.

Z602-E2B

D902-E2B

72.150 mm

2.84055 in.

(A) Top

(B) Middle

(C) Bottom (Skirt)

(a) Right-angled to Piston Pin

(b) Piston Pin Direction

Loading...

Loading...