6. CYLINDER HEAD/VALVES

SERVICE INFORMATION

GENERAL INSTRUCTIONS

The cylinder head can be serviced with the engine installed in the frame. Coolant in the

radiator and water hoses must be drained.

When assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable

parts and valve arm sliding surfaces for initial lubrication.

The valve rocker arms are lubricated by engine oil through the engine oil passages. Clean and

unclog the oil passages before assembling the cylinder head.

After disassembly, clean the removed parts and dry them with compressed air before

inspection.

After removal, mark and arrange the removed parts in order. When assembling, install them in

the reverse order of removal.

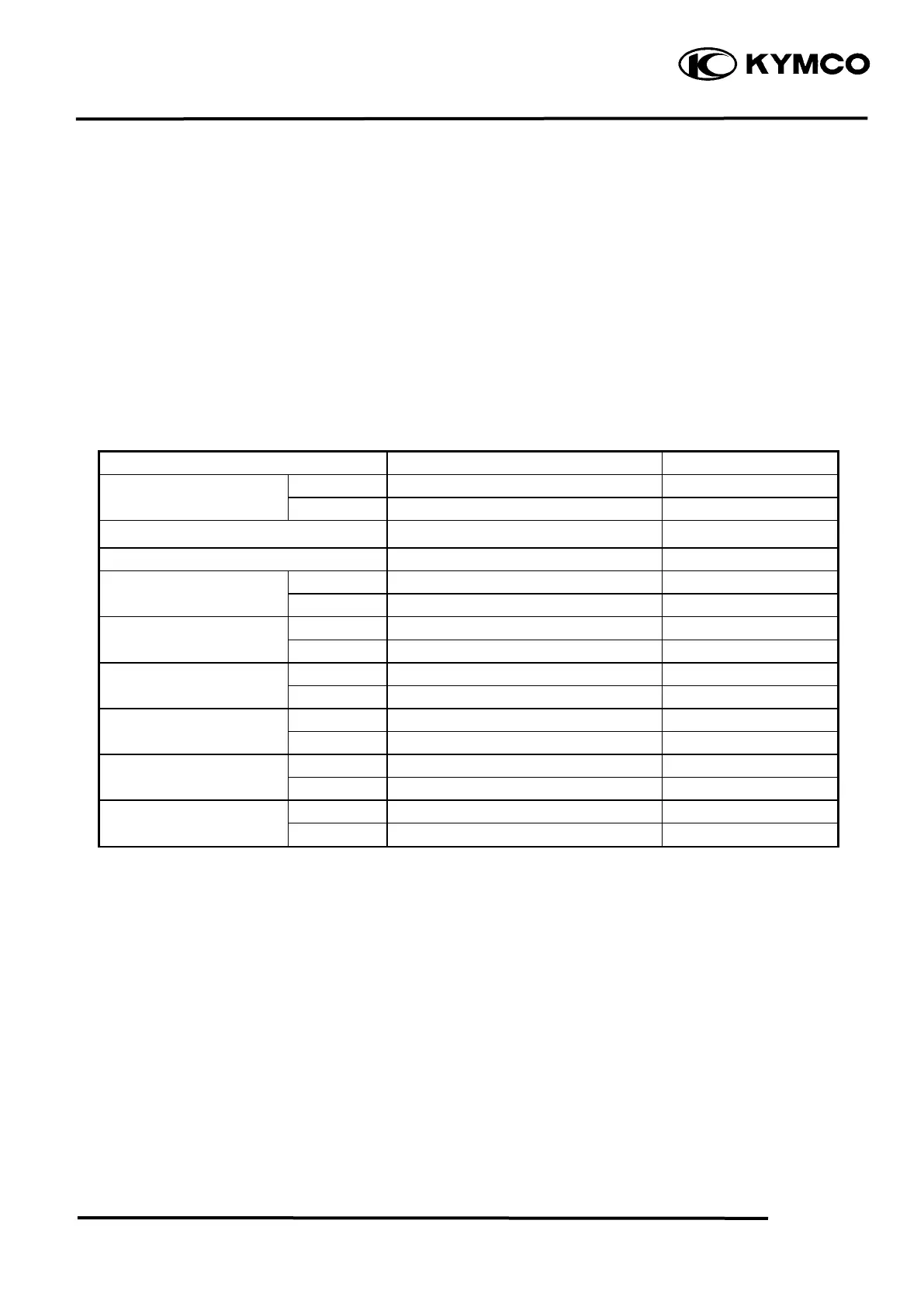

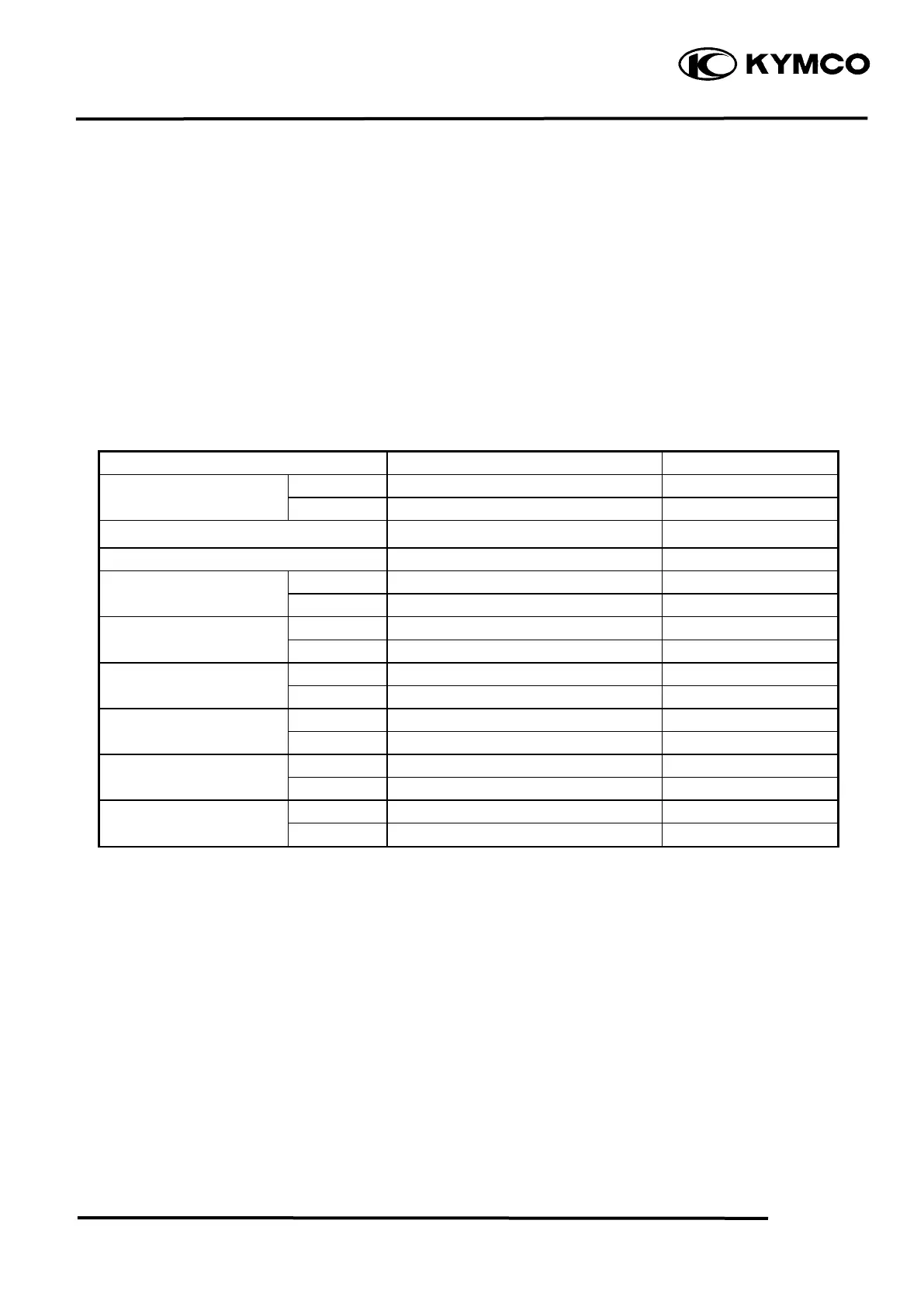

Cylinder head compression pressure

15 kg/cm

2

(213 psi, 1500 kPa)

9.972 (0.399)~9.987 (0.3995)

9.972 (0.399)~9.987 (0.3995)

4.975 (0.199)~4.99 (0.1996)

4.955 (0.1982)~4.97 (0.1988)

0.01 (0.004)~0.037 (0.0015)

0.03 (0.0012)~0.057 (0.0023)

TORQUE VALUES

Cylinder head cap nut 25 N•m (2.5 kgf•m, 18 lbf•ft) Apply engine oil to threads

Valve clearance adjusting nut 9 N•m (0.9 kgf•m, 6.5 lbf•ft) Apply engine oil to threads

Cylinder head cover bolt 12 N•m (1.2 kgf•m, 8.6 lbf•ft)

SPECIAL TOOL

Valve spring compressor E063

Loading...

Loading...