Downloaded from www.coronatechnical.com manuals search

engine

Check procedures/corrective measures

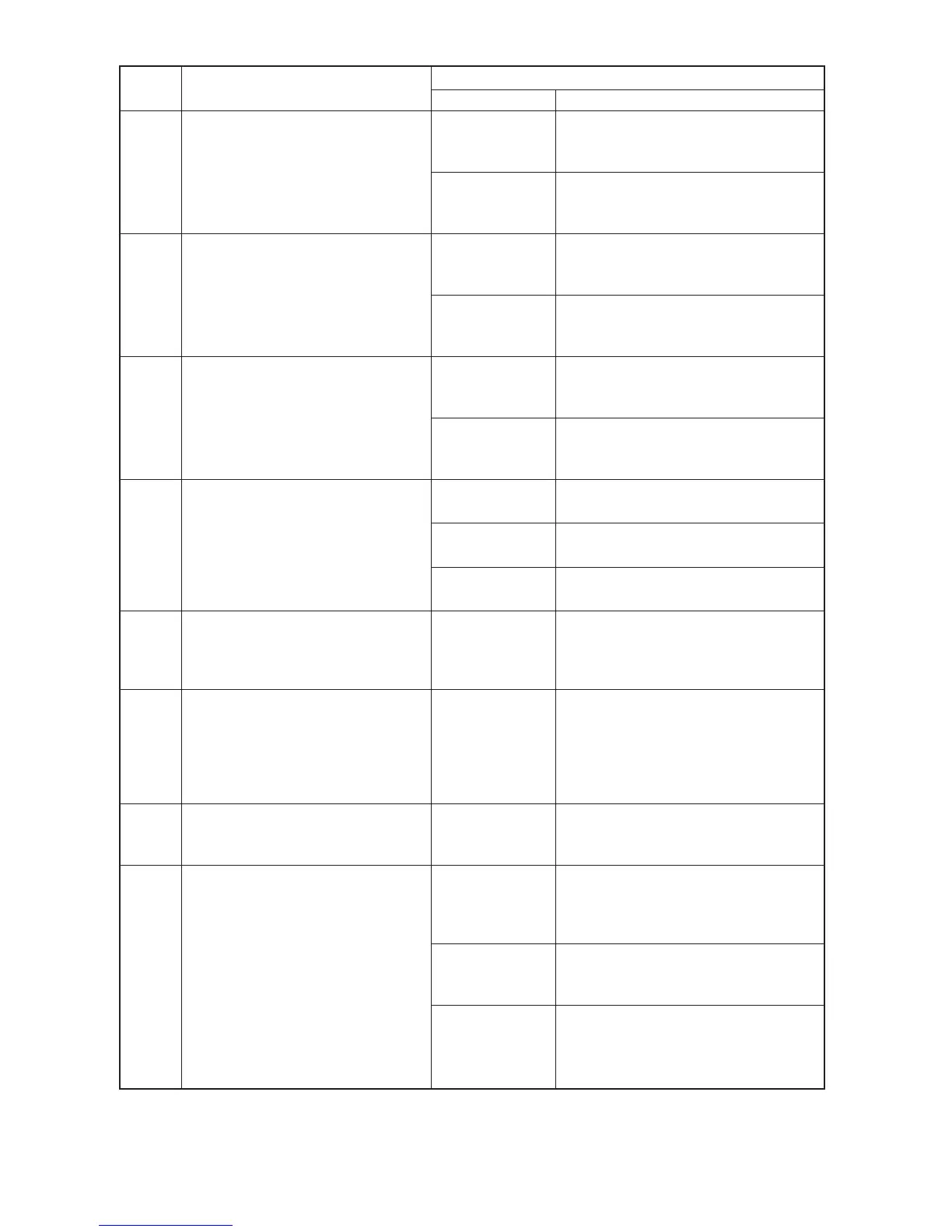

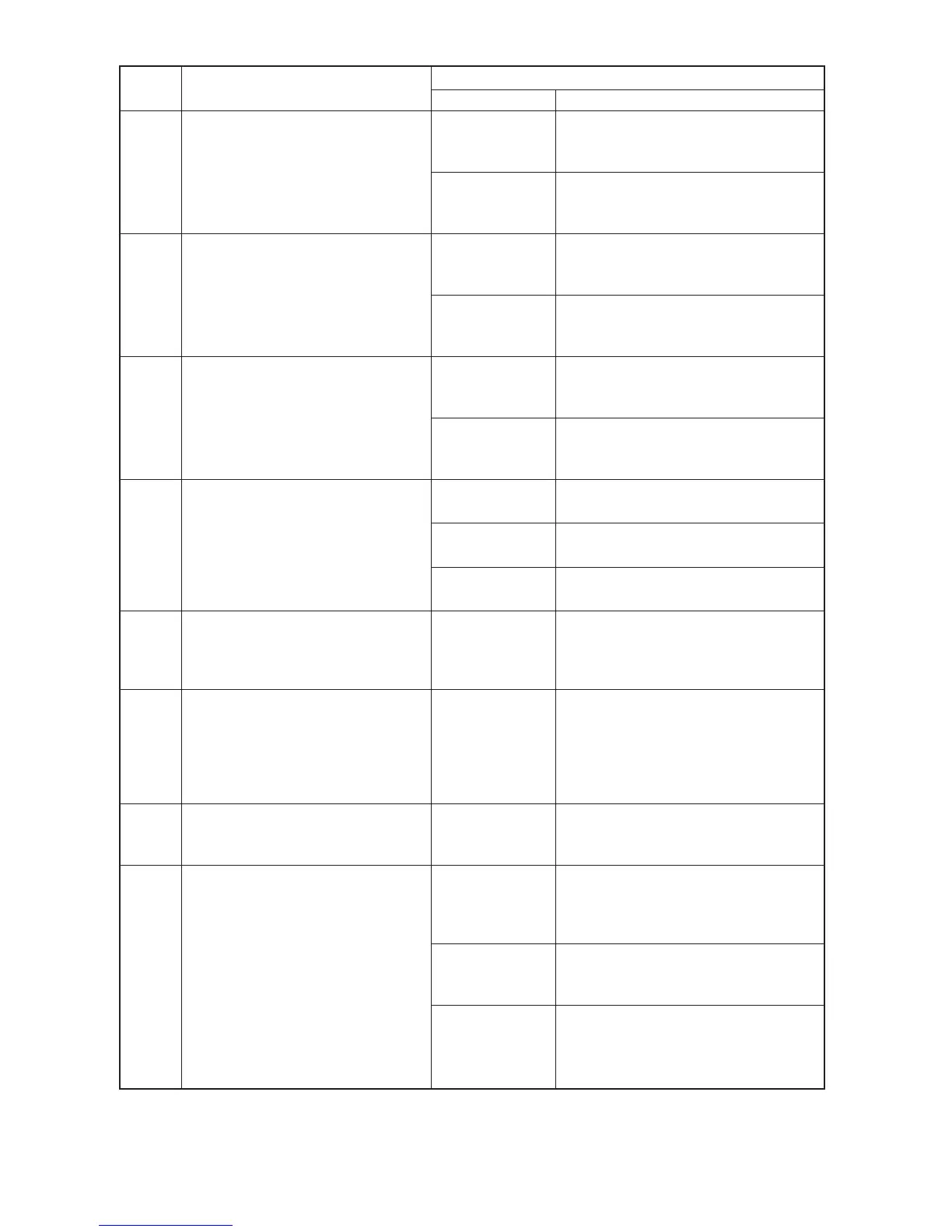

Optional first paper feeder communi-

cation problem

•

Communication fails five times suc-

cessively.

Paper feeder in-

stalled incorrectly.

Check the installation state of the paper

feeder and adjust it if it is not properly in-

stalled.

Defective main

PCB or drawer

main PCB.

Replace the main PCB or drawer main

PCB and check for correct operation.

Optional second paper feeder com-

munication problem

•

Communication fails five times suc-

cessively.

Paper feeder in-

stalled incorrectly.

Check the installation state of the paper

feeder and adjust it if it is not properly in-

stalled.

Defective main

PCB or drawer

main PCB.

Replace the main PCB or drawer main

PCB and check for correct operation.

Optional third paper feeder commu-

nication problem

•

Communication fails five times suc-

cessively.

Paper feeder in-

stalled incorrectly.

Check the installation state of the paper

feeder and adjust it if it is not properly in-

stalled.

Defective main

PCB or drawer

main PCB.

Replace the main PCB or drawer main

PCB and check for correct operation.

Bitmap (DIMM) problem

•

There is a problem with the data or

address bus of the bitmap DRAM.

Replace the main PCB and check for cor-

rect operation.

DIMM installed

incorrectly.

Check if the DIMM is inserted into the

socket on the main PCB correctly.

Replace the DIMM and check for correct

operation.

Memory input interface problem

•

Reading-in of an image does not

complete within 10 s of the start of

image transmission.

Replace the main PCB and check for cor-

rect operation.

DMA problem

•

DMA transmission of compressed,

decompressed, rotated, relocated or

blanked-out image data does not

complete within the specified period

of time.

Replace the main PCB and check for cor-

rect operation.

Image processing problem

•

JAM05 is detected twice.

Replace the engine PCB and check for

correct operation.

Drive motor problem

•

LOCK ALM signal remains high for 1

s, 1 s after the drive motor has turned

on.

Poor contact in

the main motor

connector termi-

nals.

Reinsert the connector. Also check for con-

tinuity within the connector cable. If none,

remedy or replace the cable.

Defective drive

motor rotation

control circuit.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace

if any.

“A” is displayed on the operation panel.

Loading...

Loading...