10

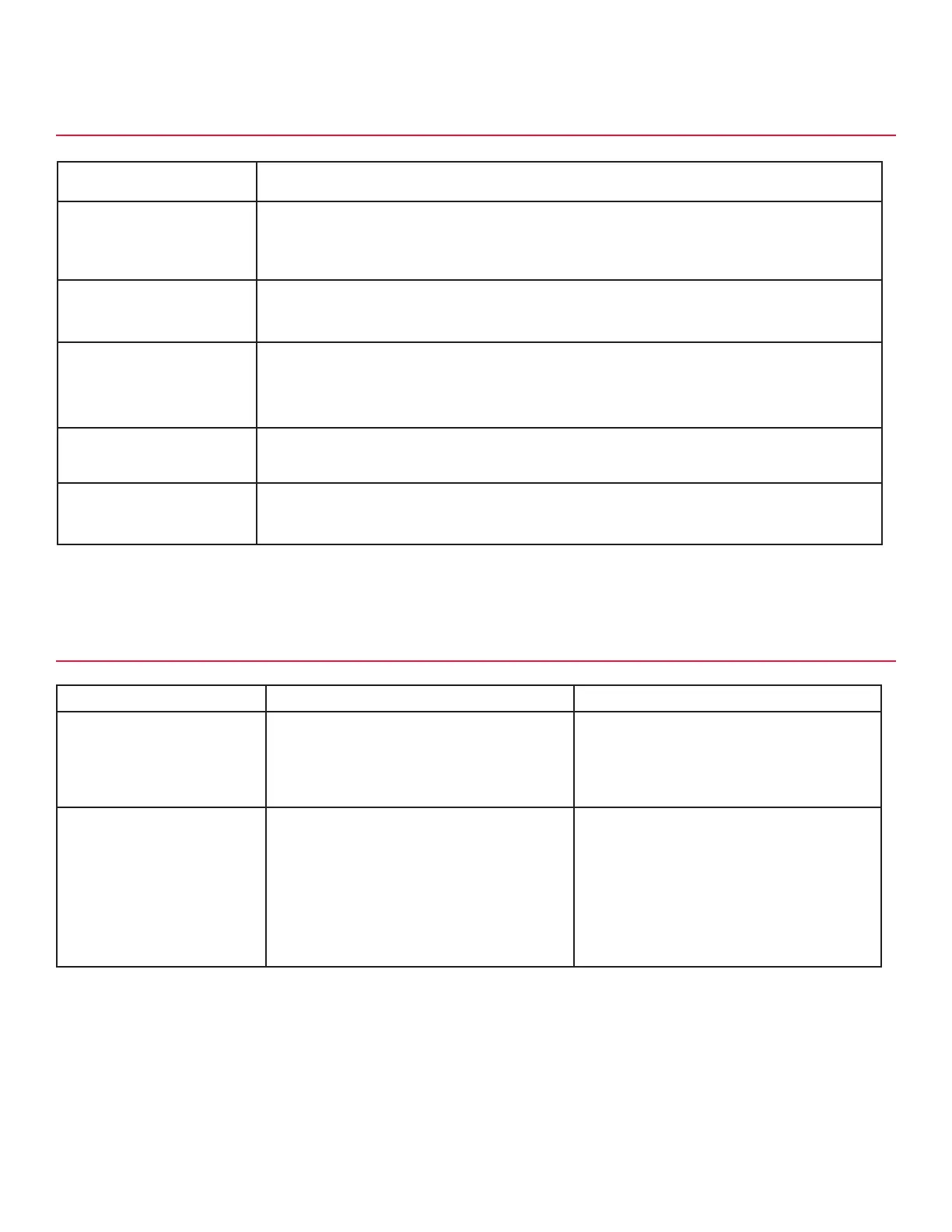

TROUBLESHOOTING

Unit Troubleshooting

TROUBLE CAUSE REMEDY

Insucient water ow. 1. Insucient incoming water supply pres-

sure.

2. Foreign debris in water line.

1. Verify incoming water supply pressure is a

minimum of 25 PSI (0.172 MPA).

2. Clean out any foreign material to ensure

smooth, free water movement.

Insucient syrup ow. 1. Insucent CO

2

pressure to BIB pumps.

2. Out of CO

2

.

3. Foreign debris in syrup line.

4. Bad syrup pump.

1. Adjust CO

2

pressure to 80 PSI (0.550

MPA) [minimum 70 PSI (0.480 MPA)] for

BIB pumps.

2. Replace CO

2

tank/rell.

3. Clean out any foreign material to ensure

smooth free syrup movement.

4. Replace BIB pump.

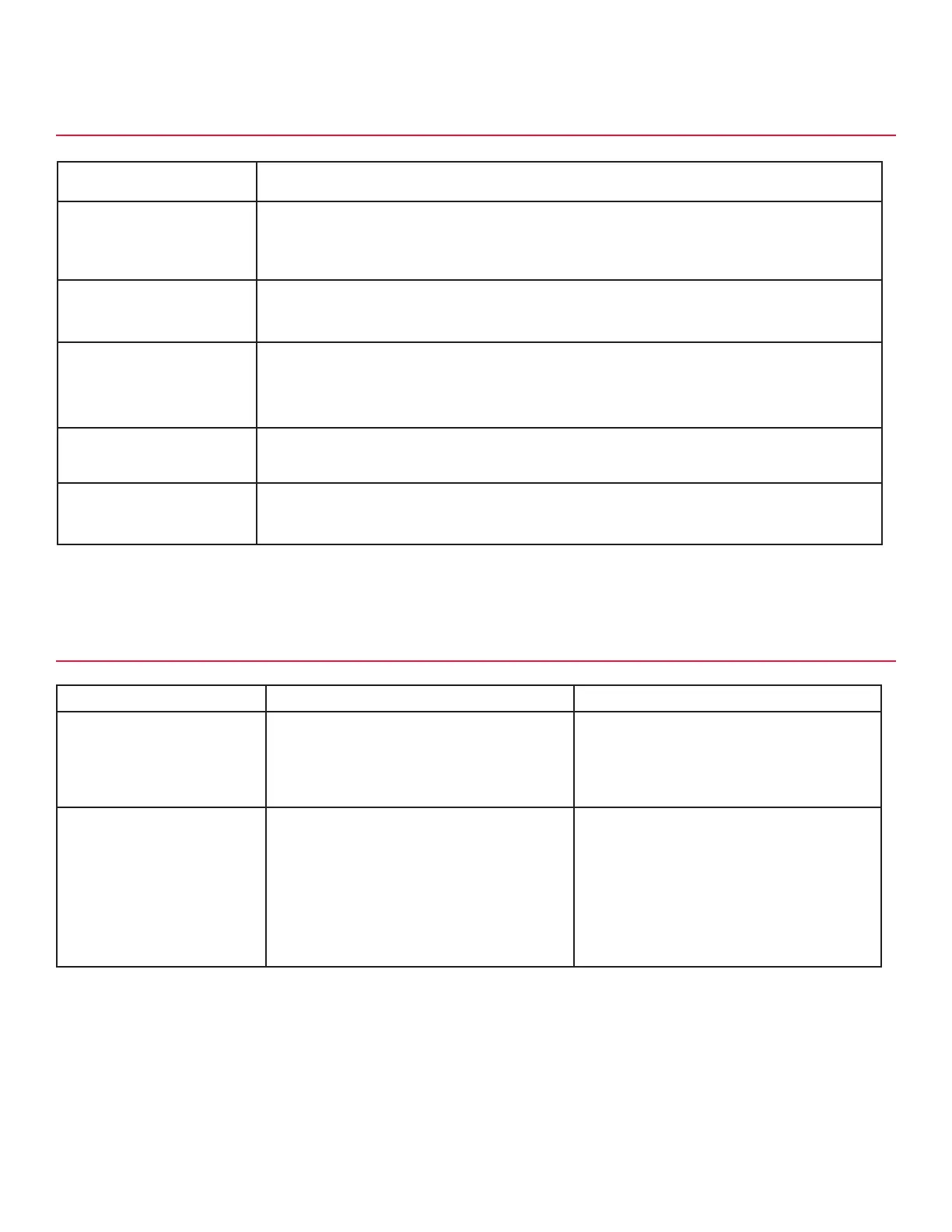

Scheduled Maintenance

MAINTENANCE

As Needed

• Keep exterior surfaces of chiller clean using a clean, damp cloth.

Daily

• With a clean cloth and warm water, wipe o all of the unit’s exterior surfaces. DO NOT USE

ABRASIVE SOAPS OR STRONG DETERGENTS.

Weekly

• Taste each product for o-tastes.

Monthly

• Unplug the chiller from the power source.

• Remove the bonnet and clean the dirt from the condenser using a soft brush.

• Replace the bonnet and plug in the unit.

Every Six Months

• Clean and sanitize the unit using the appropriate procedures outlined in the Cleaning and

Sanitizing section of this manual.

Yearly

• Clean water bath interior, including evaporator coils and refrigeration components.

• Clean the entire exterior of the unit.

Loading...

Loading...