10

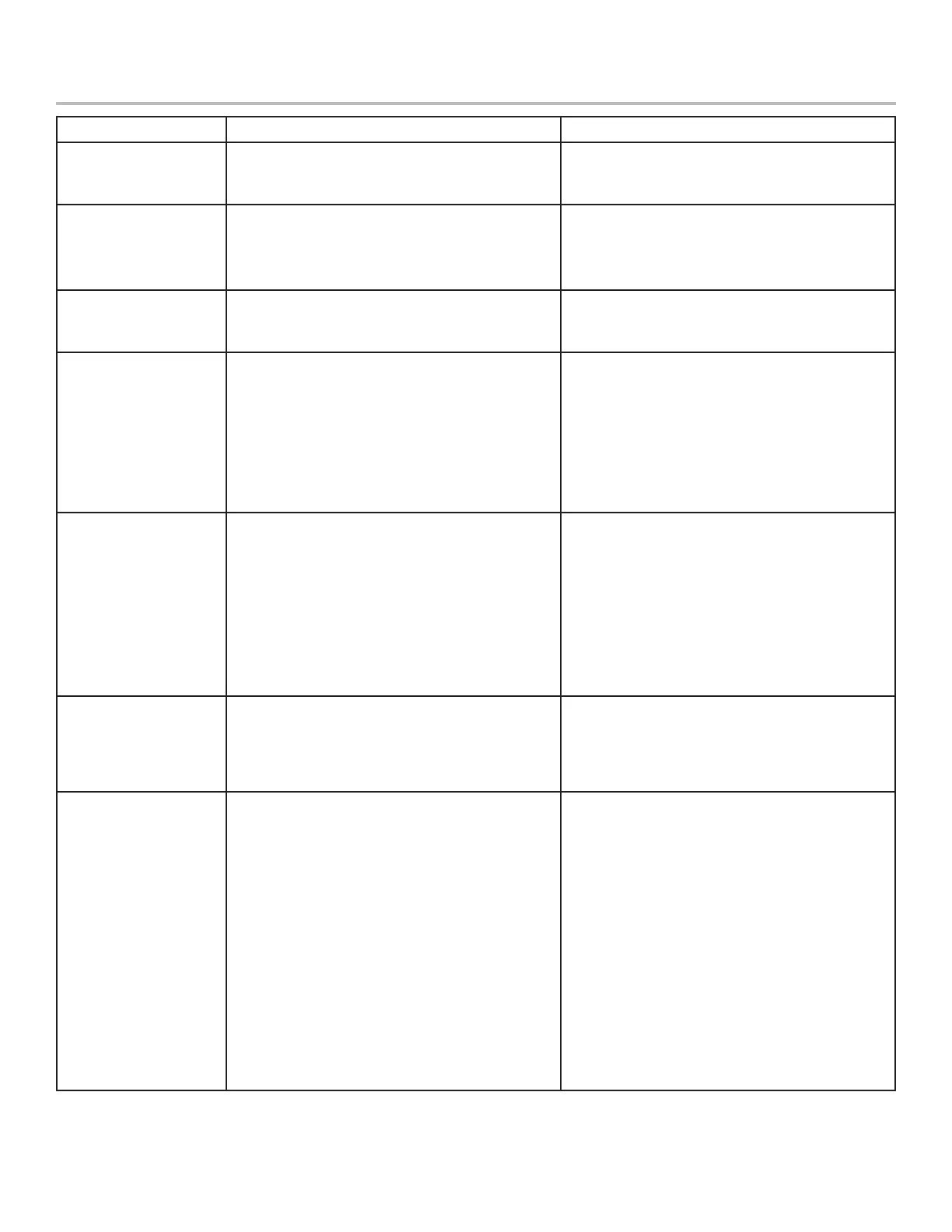

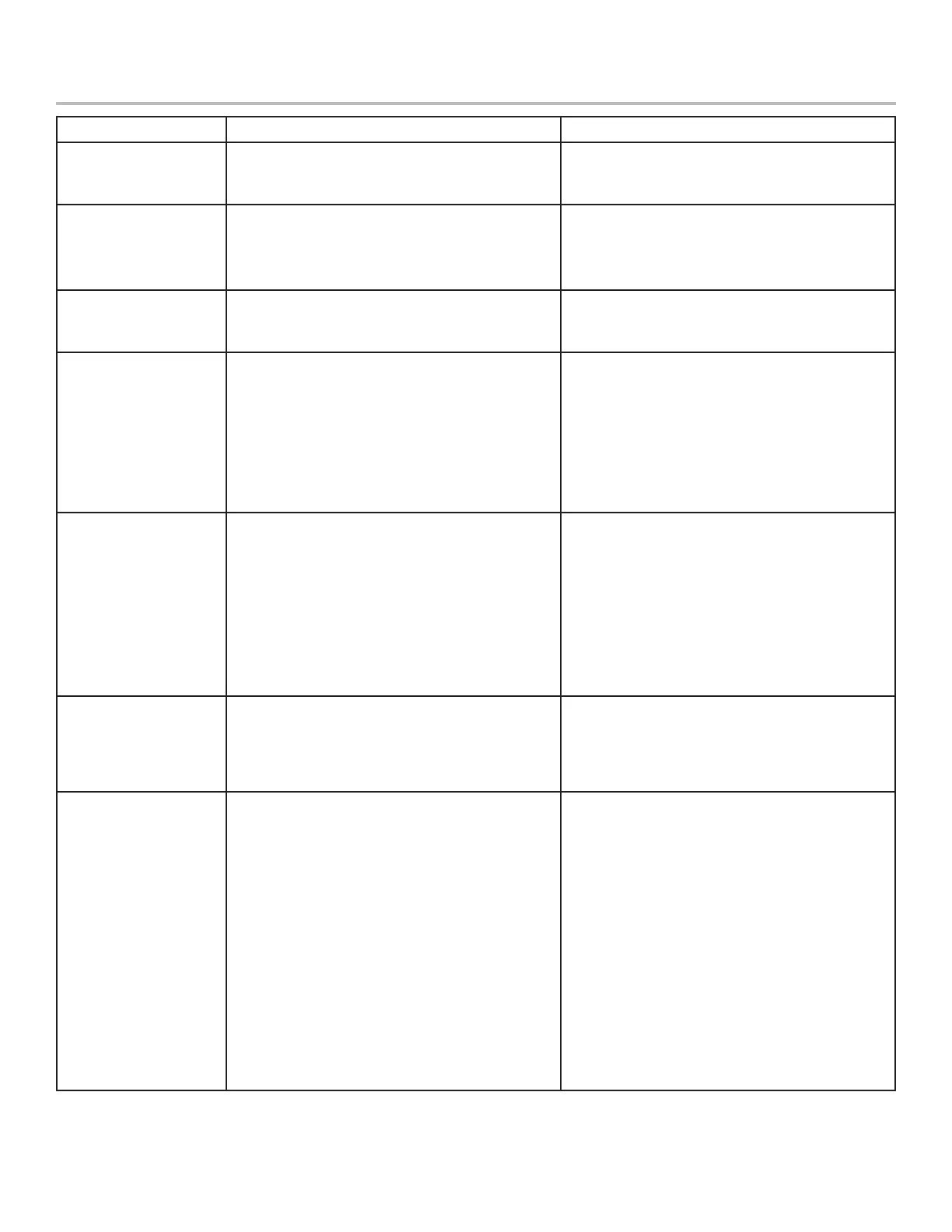

DISPENSER TROUBLESHOOTING

TROUBLE CAUSE REMEDY

Water leakage around

nozzle.

1. O-ring not properly installed above diuser

2. O-ring is damaged or missing.

1. Install or replace o-ring correctly.

2. Replace o-ring.

Leakage between upper

and lower bodies.

1. Gap between upper and lower valve bodies.

2. Worn or damaged paddle arm assemblies.

3. Cracked valve bodies

1. Tighten all six (6) retaining screws.

2. Replace paddle arm assemblies.

3. Replace Valve Body.

Miscellaneous leakage. 1. Gap between parts.

2. Damaged or improperly installed o-rings.

1. Tighten appropriate retaining screws

2. Replace or adjust appropriate o-rings

Insucient water ow. 1. Insucient incoming supply water pressure.

2. Shuto on mounting block not fully open.

3. Foreign debris in water ow control.

4. Foreign debris in water pump strainer

1. Verify incoming supply water pressure is a

minimum of 25 psi (0.172 MPa).

2. Open shuto fully.

3. Remove water ow control from upper body

and clean out any foreign material to ensure

smooth free spool movement.

4. Remove water pump strainer and clean.

Insucient syrup ow. 1. Insucient CO

2

pressure to BIB pumps.

2. Out of CO

2

.

3. Shuto on mounting block not fully open.

4. Foreign debris in syrup ow control.

5. Bad syrup pump.

1. Adjust CO

2

pressure to 80 psi (0.550 MPa)

[minimum 70 psi (0.480 MPa)] for BIB pumps.

2. Replace CO

2

tank/rell.

3. Open shuto fully.

4. Remove syrup ow control form upper body

and clean out any foreign material to ensure

smooth free spool movement.

5. Replace BIB pump.

Erratic ratio. 1. Incoming water and/or syrup supply not at

minimum owing pressure.

2. Foreign debris in water and/or syrup ow

controls.

1. Check pressure and adjust

2. Remove ow controls from upper body and

clean out any foreign material to ensure

smooth free spool movement.

No product dispensed 1. Water and syrup shut-os on mounting block

not fully open.

2. The key switch on an electric valve is in the

OFF position.

3. Cup lever arm or ID panel actuator on electric

valve is not actuating the switch.

4. Electric current not reaching valve.

5. Improper or inadequate water or syrup supply.

6. Transformer Failure

7. Bad valve solenoid(s)

1. Open shuto fully.

2. Turn key switch to ON position.

3. Repair

4. Check electric current supplied to valve. If

current is adequate, check solenoid coil and

switch, and replace if necessary.

5. Remove valve from mounting block and open

shut-os slightly and check water and syrup

ow. If no ow, check dispenser for freeze-up

or other problems

6. Reset transformer circuit breaker. If breaker

trips again check for pinched wire harness at

back-blocks

7. Replace Solenoid(s)

Loading...

Loading...