Maintenance 425HD-MD/doc101602 5-5

Maintenance

Maintenance Schedule

5

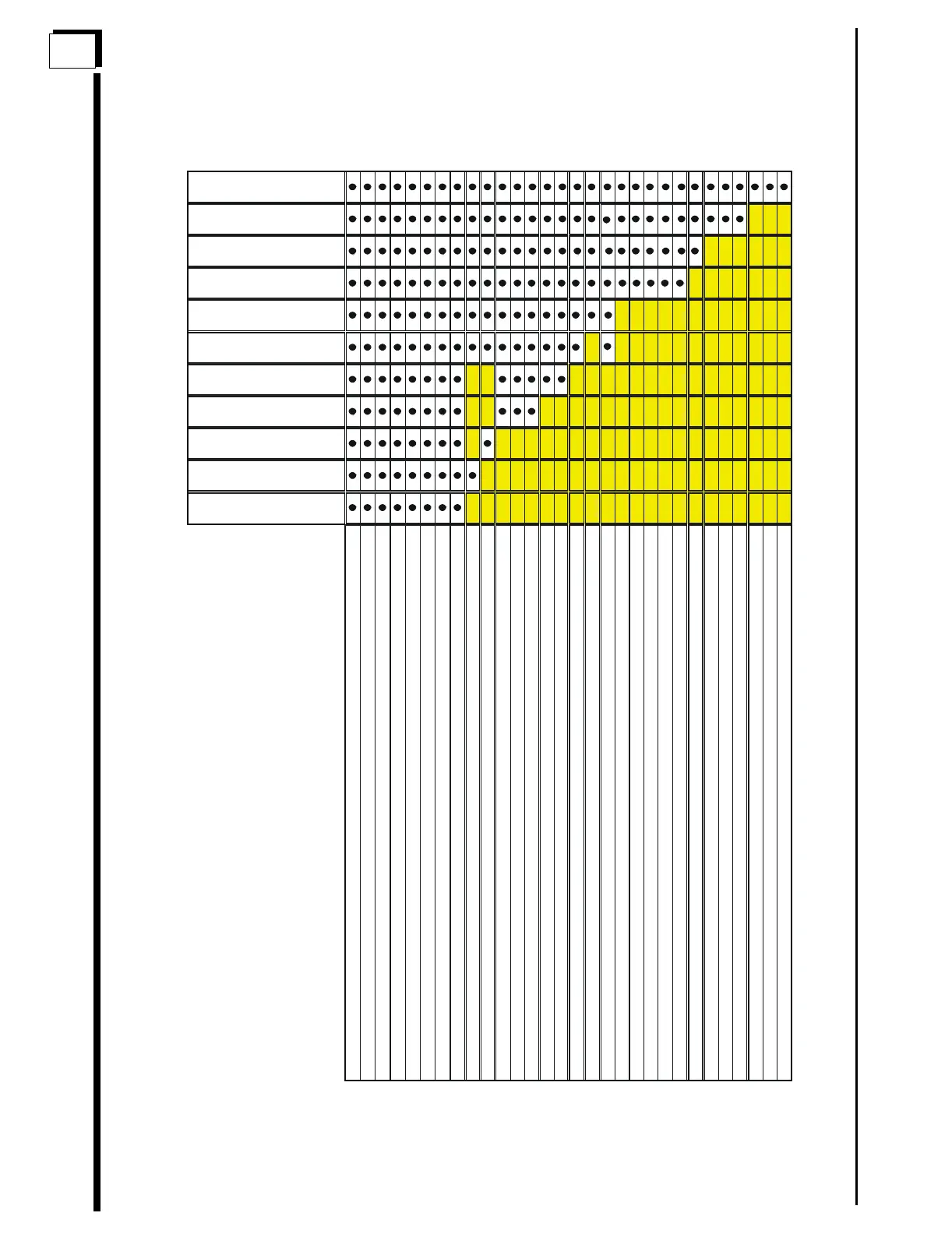

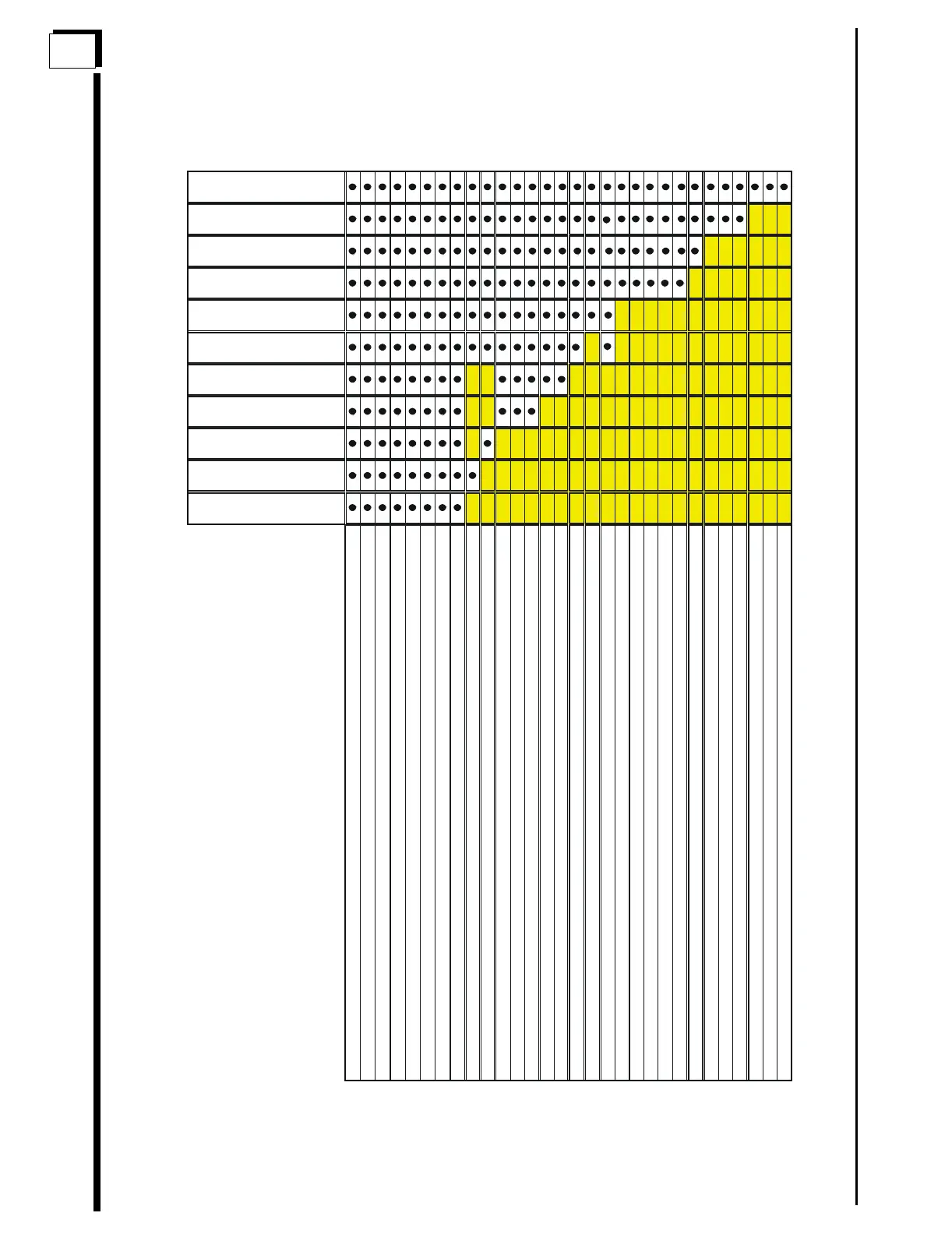

5.13 Maintenance Schedule

Every 8 Hours

First 25 Hours

First 50 Hours

Every 50 Hours

Every 100 Hours

Every 200 Hours

Every 400 Hours

Every 500 Hours

Every 800 Hours

Annual

Bi-Annual

Complete the Pre-Operation Equipment Inspection Checklist

If operating in exceptionally dusty or dirty conditions, replace filter elements if necessary

Grease all grease zerks

Inspect the spindle bearing grease seals under each deck for grease leakage or improper seals

Lubricate all joints and moving parts which are not equipped with grease zerks

Verify that all cables & hardware are functional, securely fastened and in good condition

Verify proper installation, operation, and flow of grass chute

Inspect entire Articulator for loose or entangled parts, debris, obstructions, neglected tools, other hazards

Change hydraulic oil & filter

Change engine oil & filter

Inspect engine fuel pipes and clamps

Grease all blade spindle bearing housings

Inspect all bronze bushings

Clean air cleaner & filter elements

Inspect alternator & fan belts

Change engine oil & filter

Replace fuel filter cartridge

Grease the Gearbox

Replace all bronze bushings

Inspect & re-pack all wheel bearings

Flush fuel tank of debris

Flush radiator

Replace engine fan & alternator belts

Check engine valve clearance

Replace air cleaner filter elements

Change the hydraulic oil & filter

Install complete K607 Model 425D Articulator Rebuild Kit

Replace engine fuel pipes & clamps

Replace radiator hoses & clamps

Replace battery

Loading...

Loading...