5.8.3 Overview of external control parameters

n External control consists of a master controller (external controller) and

a slave controller (internal controller). The temperature of the consumer

to be temperature controlled is also required. In general this is deter-

mined with an external “Pt100 sensor”.

n The master controller compares the set temperature with the external

temperature (consumer temperature) and, from these temperatures,

calculates the set temperature (set_internal) for the slave controller

(internal controller).

n The slave controller compares the set temperature (set_internal) with

the outflow temperature and calculates the actuating signal, i.e. the

measurement used for heating or cooling.

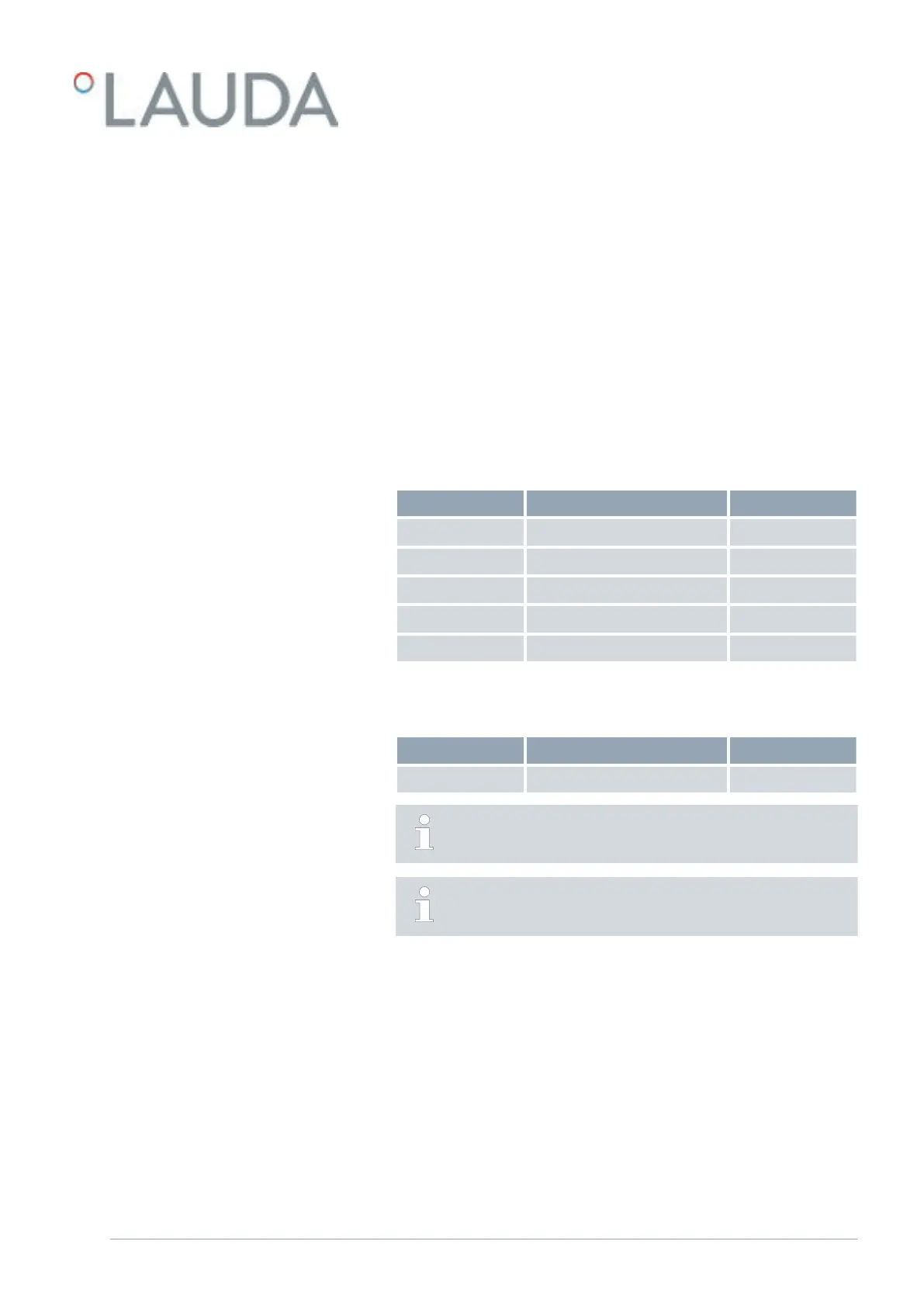

Table 33: The following control parameters can be adapted on the master

controller (external controller):

Characteristics Designation Unit

Kpe Amplification factor -

Tne Adjustment time s

Tve Hold-back time s

Tde Attenuation time s

Prop_E Proportional range K

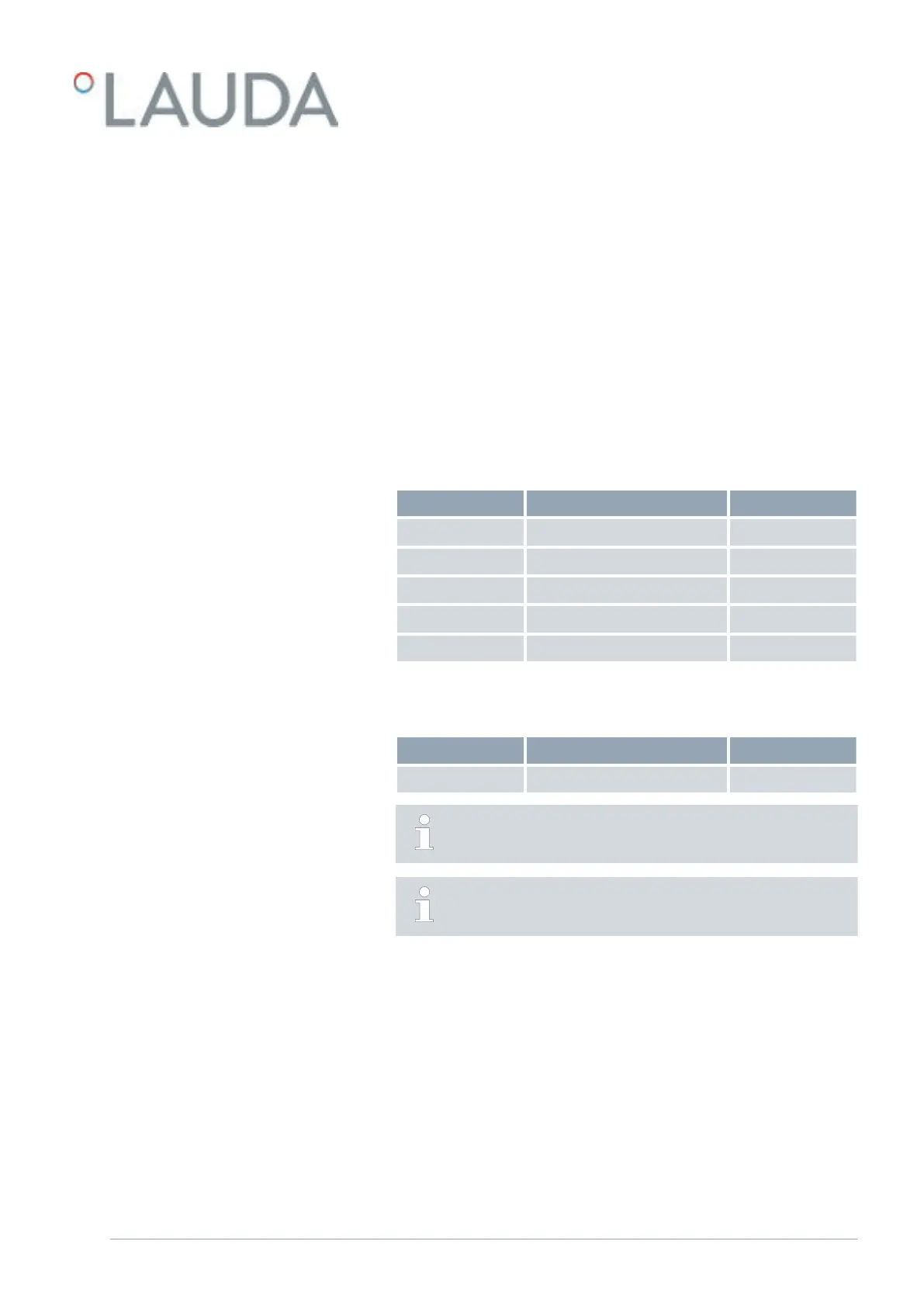

Table 34: The following control parameters can be adapted on the slave

controller (internal controller):

Characteristics Designation Unit

Xpf Proportional range K

If Tv manual/auto is set to auto , Tv and Tde cannot be modified. In

this case, they are derived with fixed factors of Tne.

The temperature limits Tih and Til also have an eect on the

control.

If a temperature jump is specified via set temperature T

set

, the control may

set an outflow temperature which is considerably higher (e.g. 50 K, possible

problem with enamel reactors) than the temperature T

ext

required in the

external application. Therefore, there is a correction limitation that specifies

the maximum permitted deviation between the temperature at the outflow

T

int

and the temperature in the external consumer T

ext

.

1. Press the [Enter key] to open the menu.

2.

Select the menu items Setup Control Correction limit..

An entry window opens for the numerical value.

Correction limitation

V6 Integral Process Thermostats and High-Temperature Thermostats 83 / 198

Loading...

Loading...