LAUNCH Tyre Changer (TWC-502RMB)

4

Operation

Attention:

The use of this machine is reserved to specially

trained and authorized personnel. Use appropriate

equipment, tools and personal protective equipment,

such as eye-glasses, ear-plugs and working boots,

when operating the tyre changer. Make sure that the

power, air sources and the oil level in the oil cup are

in accordance with the requirements.

Principles

l To avoid damage when mounting and demounting

tyre, especially the alloy ones, use the tyre lever

offered by manufacturer.

l For easier demounting and better protection of the

tyre and rim, lubricate the area between the rim and

tyre bead, where the bead breaker shoe goes in,

with industrial lubricant or thick soap solution.

l Check for damages (distortions, surface damages,

excessive runout, erosion or overall wear) before

demounting.

l Pay special attention to rotary direction marked on

some flanges or tyres.

l Fit the tyre on the rim of matched size.

l Never ignore the mounting and demounting

requirements of the special wheel.

l When inflating the tyre, make sure the pressure

increases in an even way. Pay attention to status of

the tyre bead.

Demounting Tyre

Preparing

l Deflate the tyre thoroughly.

l Remove all the foreign substance and weights from

the rim (Fig. 03).

Fig.03

Demounting

Attention:

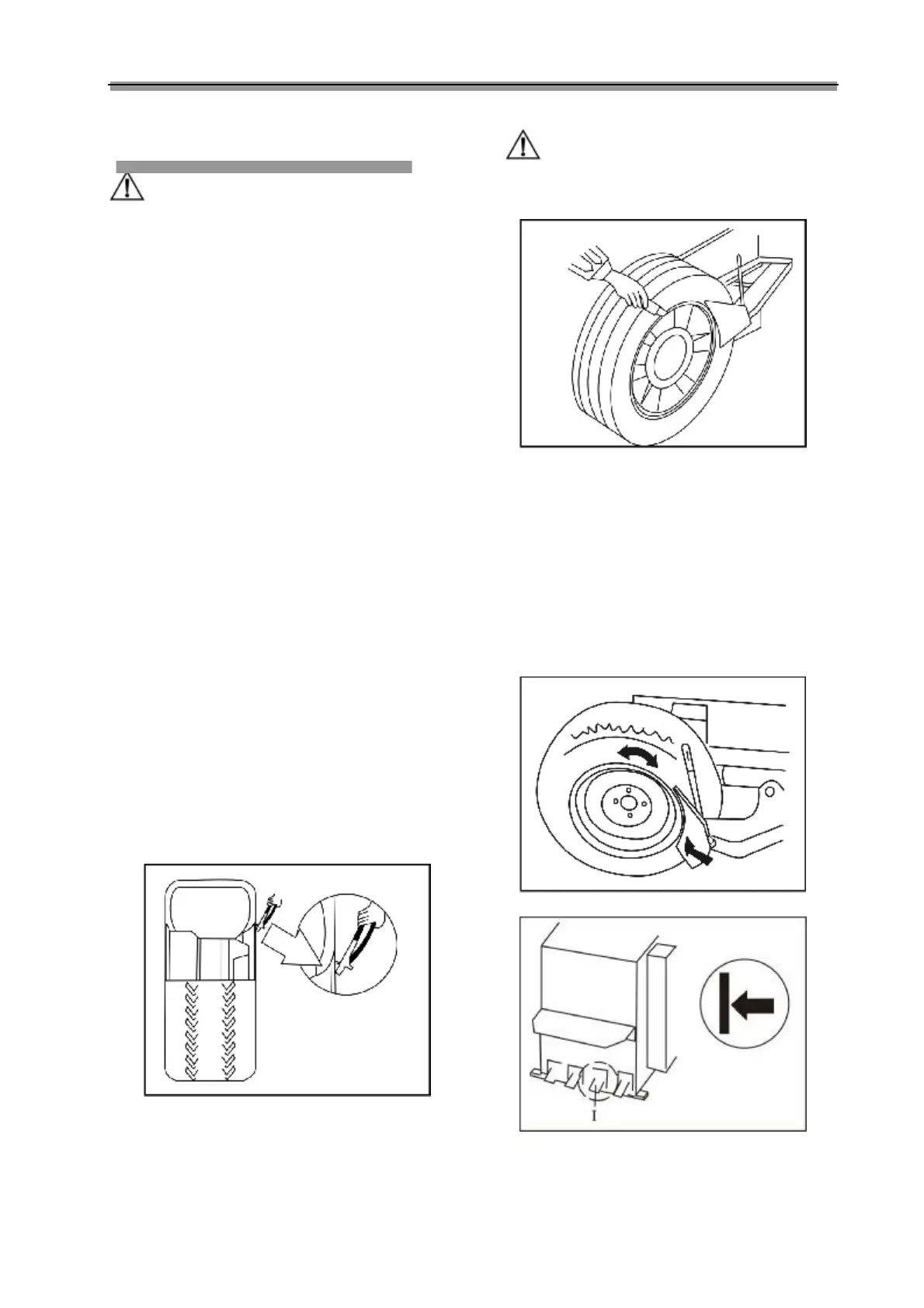

Lubricate the bead with a brush dipped in soap

solution before the shoe touches the bead.

Otherwise the tyre bead will be worn (Fig. 04).

Fig.04

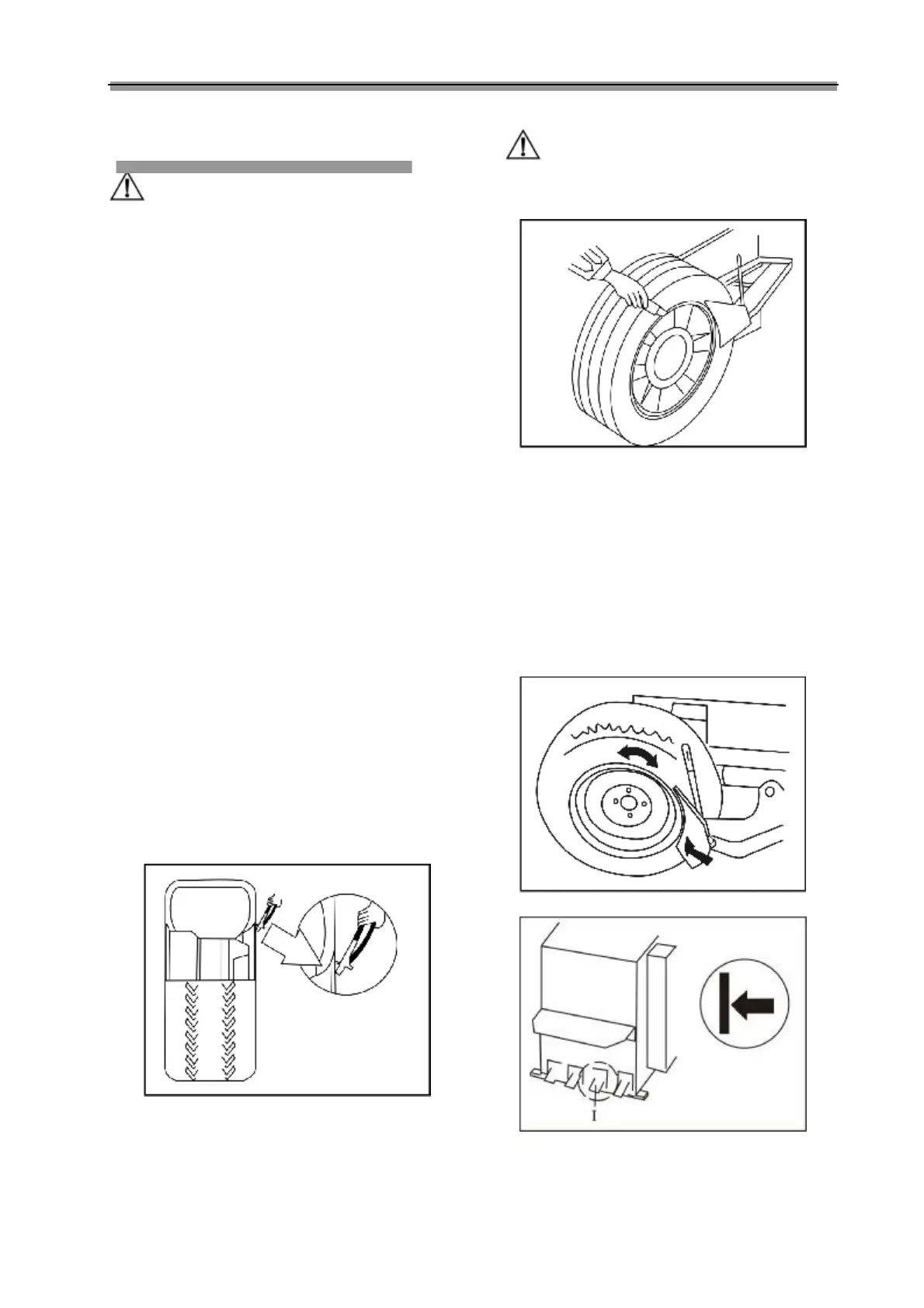

l Place the tyre between the bead breaker shoe and

rubber pad and keep the shoe between the tyre

bead and rim, about 1cm to the bead (Fig. 05).

Depress pedal (I)(Fig. 06) to separate the tyre from

rim.

l Repeat the above steps on other part of the tyre to

get the tyre separated thoroughly from the rim.

l Place the wheel on the turntable. For the asymmetric

deep groove rim, keep the narrow rim upward.

l Depress pedal H(Fig.07) to the end to clamp the rim.

Fig.05

Fig.06

Loading...

Loading...