5

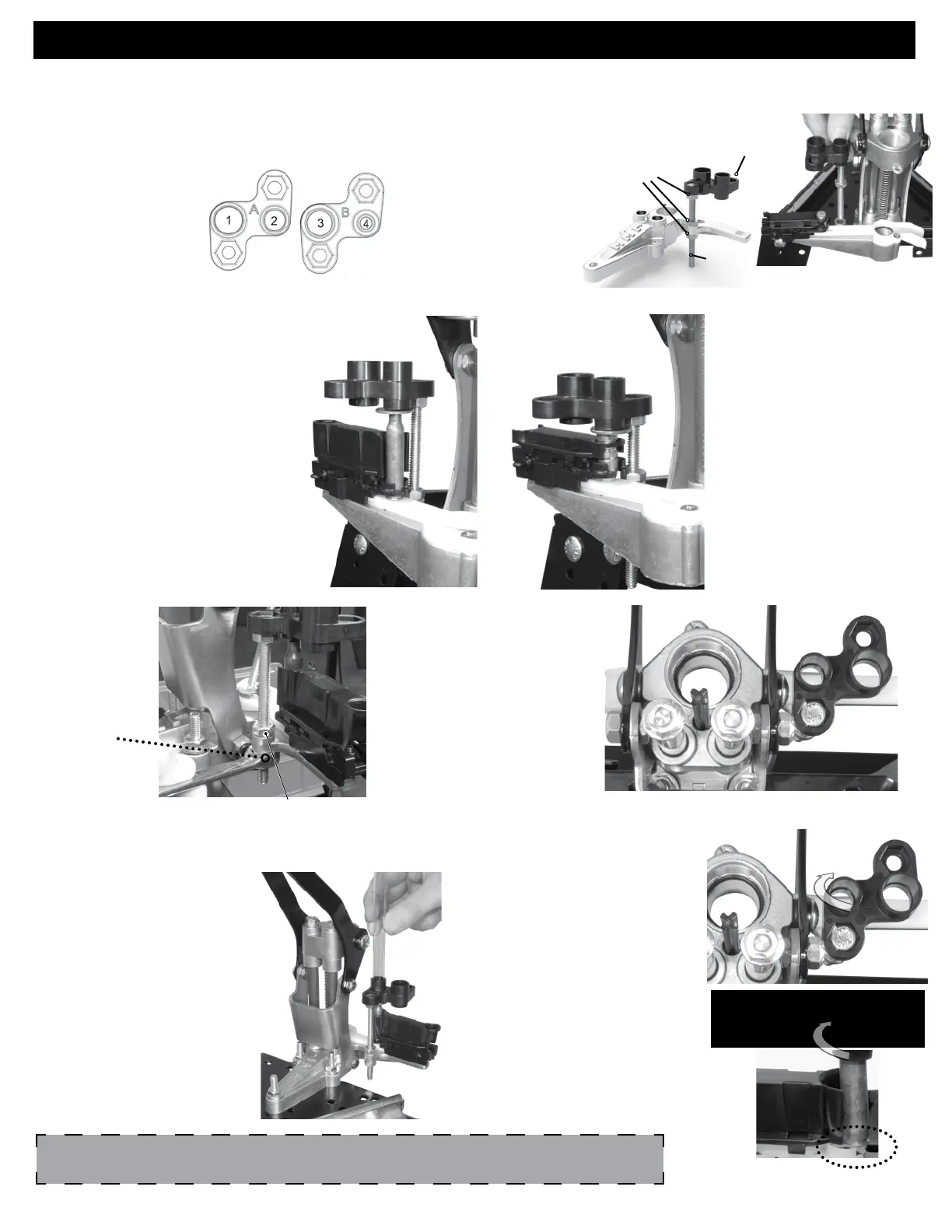

Place empty case|bullet into your

previously configured and adjusted

case inserter and position as shown.

Adjust the nut up or down on the tube

support bolt so there is approximately

a coins thickness between the bottom

of the tube support and the top of the

case. Minimizing the clearance gives

the best results.

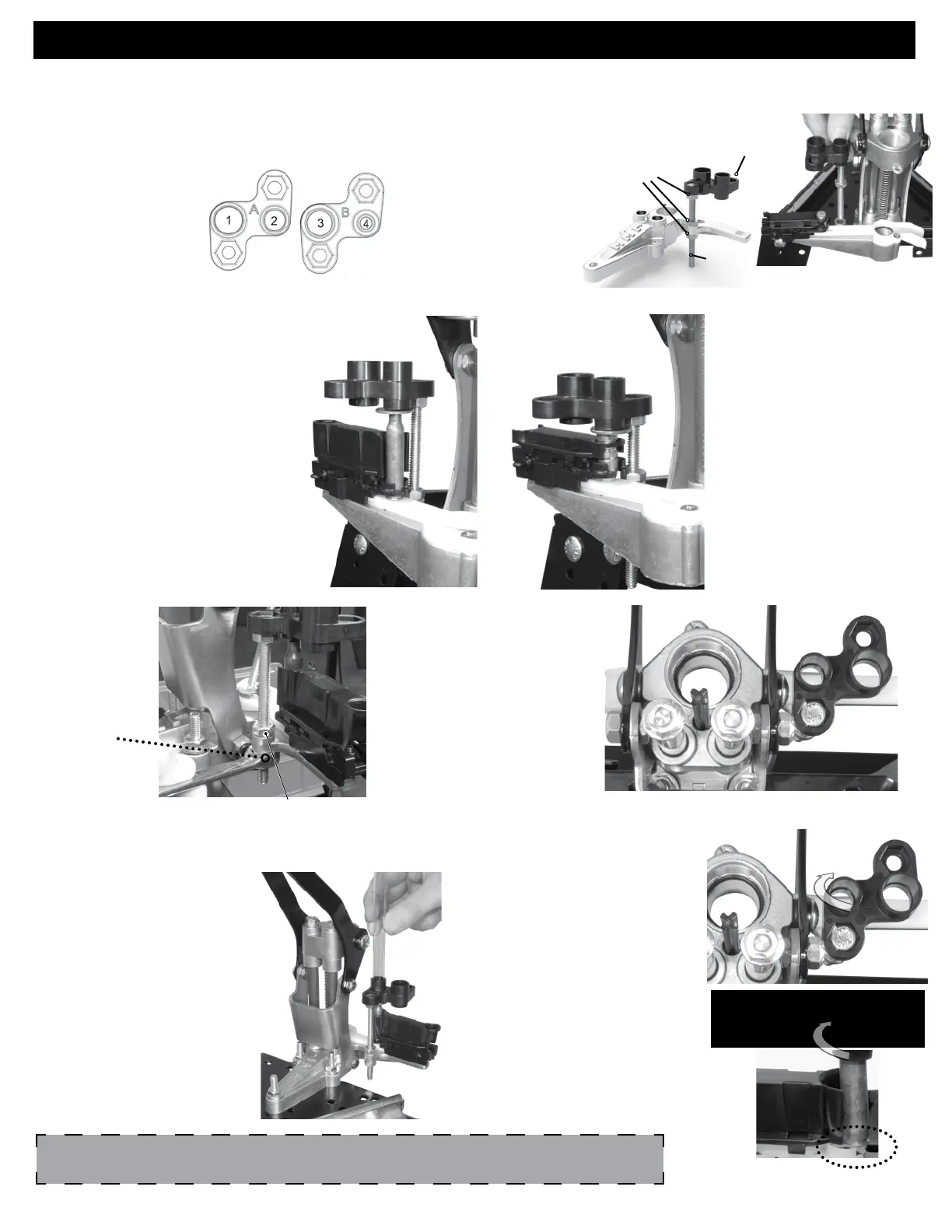

Select appropriate tube

support PA4360A or

PA4360B by passing

your bullet or case

through. Select the

smallest hole that the

case or bullet will flow

through unrestricted.

Insert ¼” support bolt

into the adjacent hole

you just selected. Secure

bolt with nut. Thread

another nut onto bolt

about half way. Slide the

bolt into the APP base

casting as shown.

FIG. 2

PA4360A PA4360B

Orientation of tube support

FT2457

¼ support bolt

FT1994 (qty. 3)

¼-20 x 7/16 nuts

PA4360A or B

Tube Support

INSTALLING TUBE SUPPORTS

When you secure

the nut, hold and

orientate the tube

support so it does

not interfere with

the press handle

during operation

as shown.

Install clear feed tube for the

appropriate size hole in tube

support.

Note: due to the large

manufacturer’s tolerance on

these tubes, some may fit

loosely in the tube support.

This does not aect anything,

you can tighten the fit with a

round or two of clear tape.

Install the

last nut on

to the tube

support bolt

underneath

base casting,

and tighten nut

above rail with

7

/

16

” wrench.

Lower handle. Re-attach spring to

case inserter actuator. Cycle a few

cases. If the cases drop too soon,

they may rest on top of feed fingers.

Rotate the feed tube support

farther away (clockwise) from

the press to delay the dropping.

Because of the wide range of

diameters and rim configurations,

you will have to fine tune this

position to provide reliable feeding.

Tighten nut above rail

with

7

/

16

” wrench.

Note: while decapping mixed range brass, you may encounter cases with damaged rims that won’t

feed into shell holder. Remove this case and discard or repair rim damage to allow easy entry.

Case rests on fingers. Rotate feed

tube support clockwise from

press to delay the drop.

Loading...

Loading...