39

39

RTJ400 User Guide

Chapter 9

Half-Blind Dovetail Joint Procedures

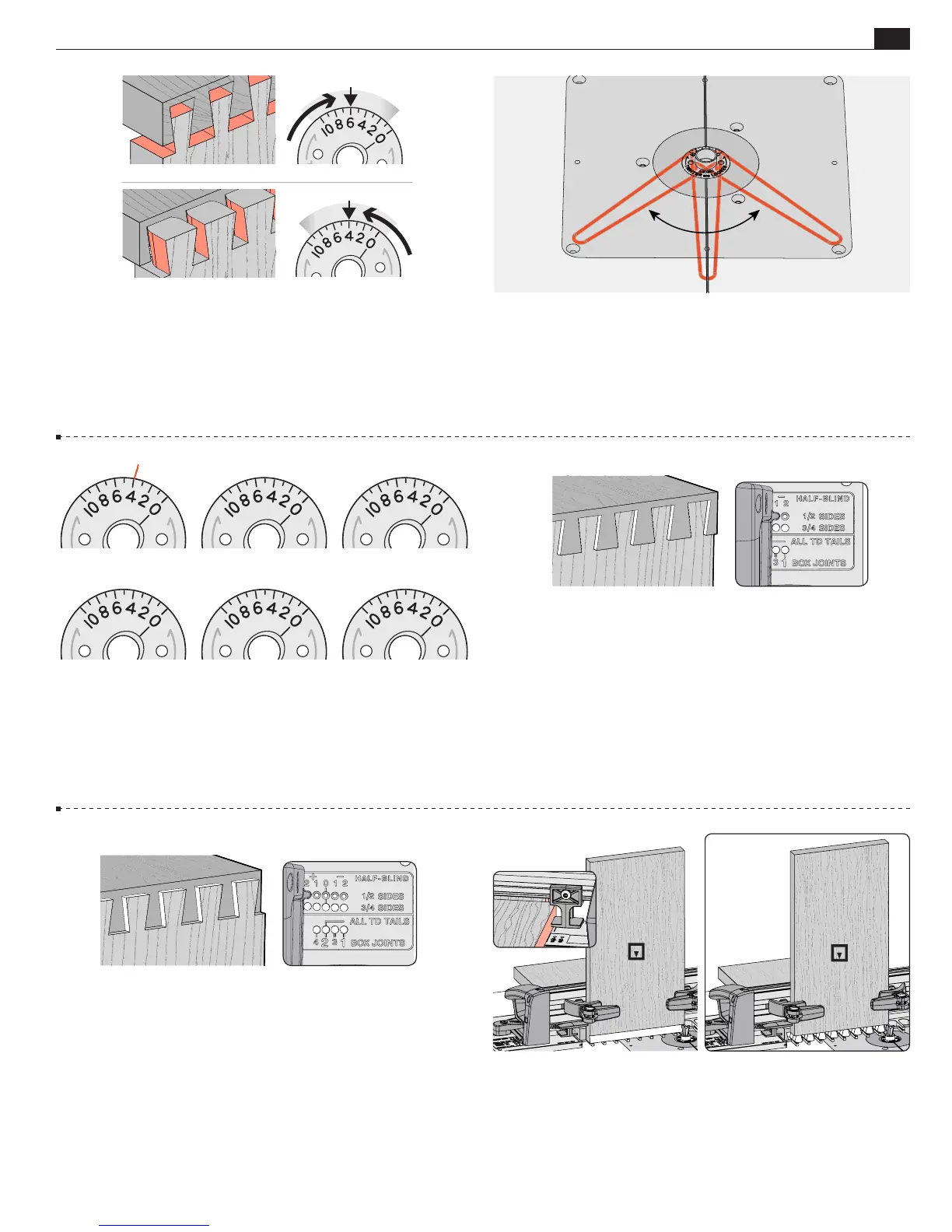

9-20 Test for Fit If the joint is too loose, turn the eBush to a

higher number with the pin wrench as shown in the next step, and

rout two fresh boards.

If the joint is too tight, turn the eBush to

a lower number and

rout two fresh boards

.

9-21

Each increment on the eBush changes the joint glue line

fit by 0.002" [0.05mm]. Half an increment, a mere 1000th inch!

Re-tighten the eBush nut after each guide bushing adjustment.

TOO LOOSE TIGHTEN

TOO TIGHT LOOSEN

9-22 Record your perfect fit eBush setting on one of the drawings

provided above.

OVER FLUSH

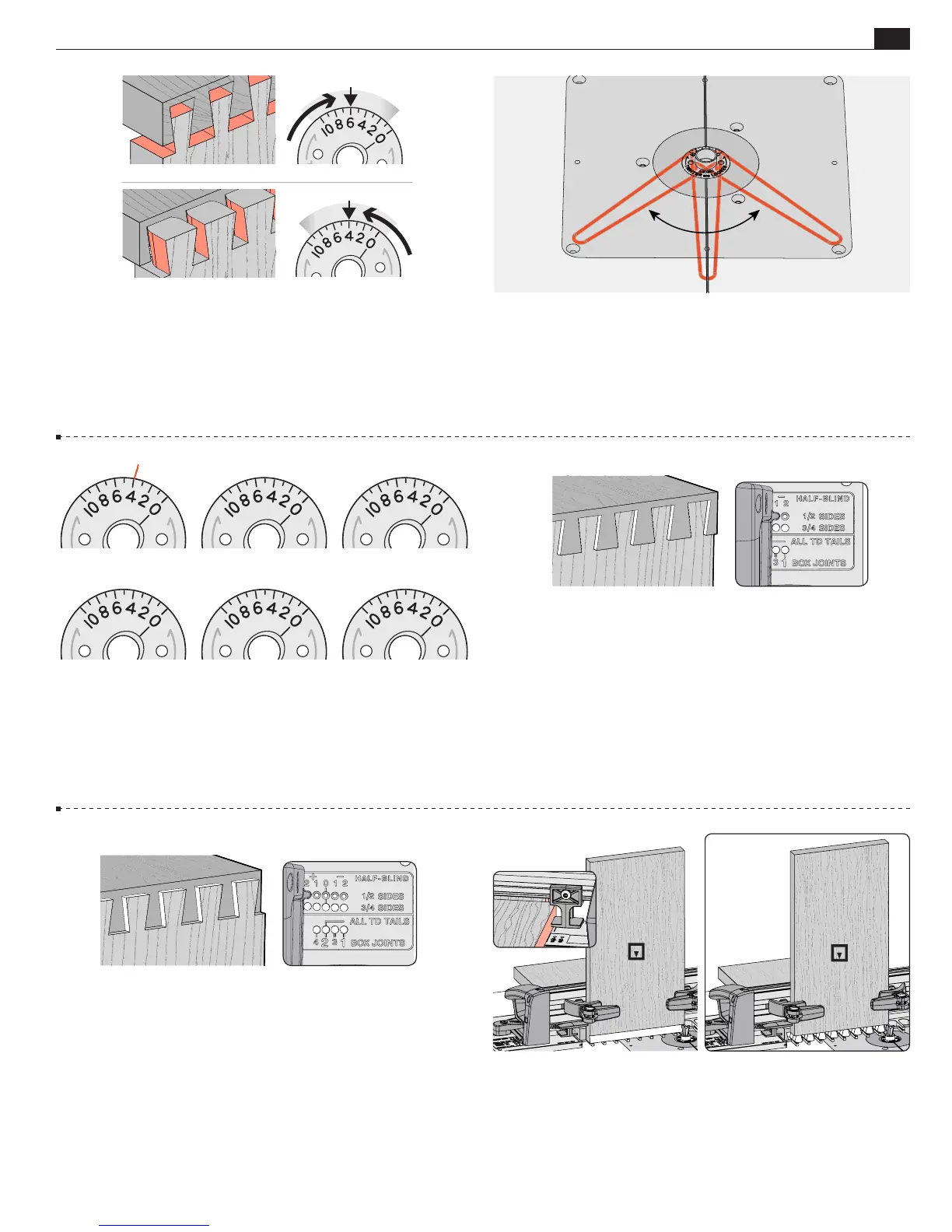

9-23 Flushness IMPORTANT NOTE: Do not adjust flushness

until correct joint tightness in previous steps is achieved.

For over flush pins

,

move the frame pin to a minus (“–”) pin

position and rout a new test joint.

You must re-center the

tail board and reposition the sidestop every time a reset for

flushness is made

. Each pin position changes the joint flushness

by 0.013"[0.33mm] Record the pin setting for future use.

Note:

Tail board thickness will not affect flushness.

UNDER FLUSH

9-24 Flushness IMPORTANT NOTE: Do not adjust flushness

until correct joint tightness in previous steps is achieved.

For under flush pins, move the frame pin to a plus (“+”) pin

position and rout a new test joint.

You must re-center the

tail board and reposition the sidestop every time a reset for

flushness is made

. Each pin position changes the joint flushness

by 0.013"[0.33mm] Record the pin setting for future use.

Note:

Tail board thickness will not affect flushness.

Sample

Leigh 120-500 Bit

9-25 Now rout the box. Left: Insert tail board 1 (corner A).

Inset: Insert pin board 1 (corner A) . Right: Rout in all openings.

Tail board 1

and pin board 1

are half complete

.

A

B

A

B

A

Loading...

Loading...