41

41

RTJ400 User Guide

Chapter 9

Half-Blind Dovetail Joint Procedures

9-33

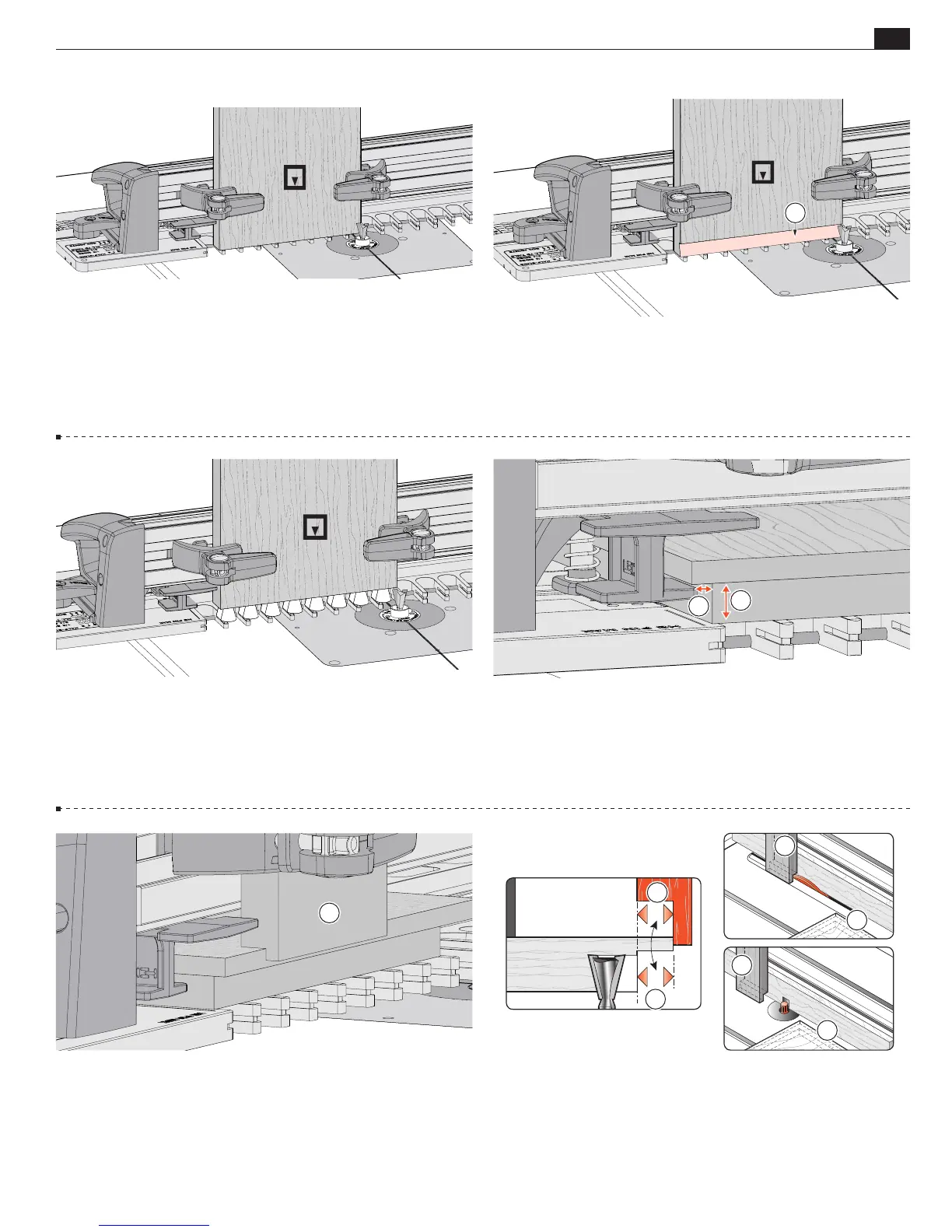

Rabbeted Drawer Fronts: Provided the rabbet on the

drawer front is less than ⅜" [9.5mm] wide

A

and more than

⅜" deep

B

, the sidestop, as previously set on the drawer side, is

correctly positioned for the rabbeted pin board.

A

C

C

D

D

A

B

9-34

Front Limit Stop: You will need to make a scrap limit

stop

A

. See the next step for instructions on how to make the

front limit stop.

9-30

Note: The pin board and tail board are routed separately

for rabbeted half-blind joints.

Center and clamp a

test

tail board

in the jig. Adjust the sidestop to touch the right edge of the board

and tighten. If you have already determined joint tightness for the

dovetail bit you’re going to use (in Step 9-22), you don’t need to

redo the test fit procedure.

Important note:

Choose a bit from

Step 9-2 with a depth of cut less than the rabbet thickness.

9-31 Make a very light, shallow climb cut, moving the jig

right to left

A

. This will leave a nice clean shoulder.

The bit will tend to drive the jig to the right, so make the

cut light and with a firm grip.

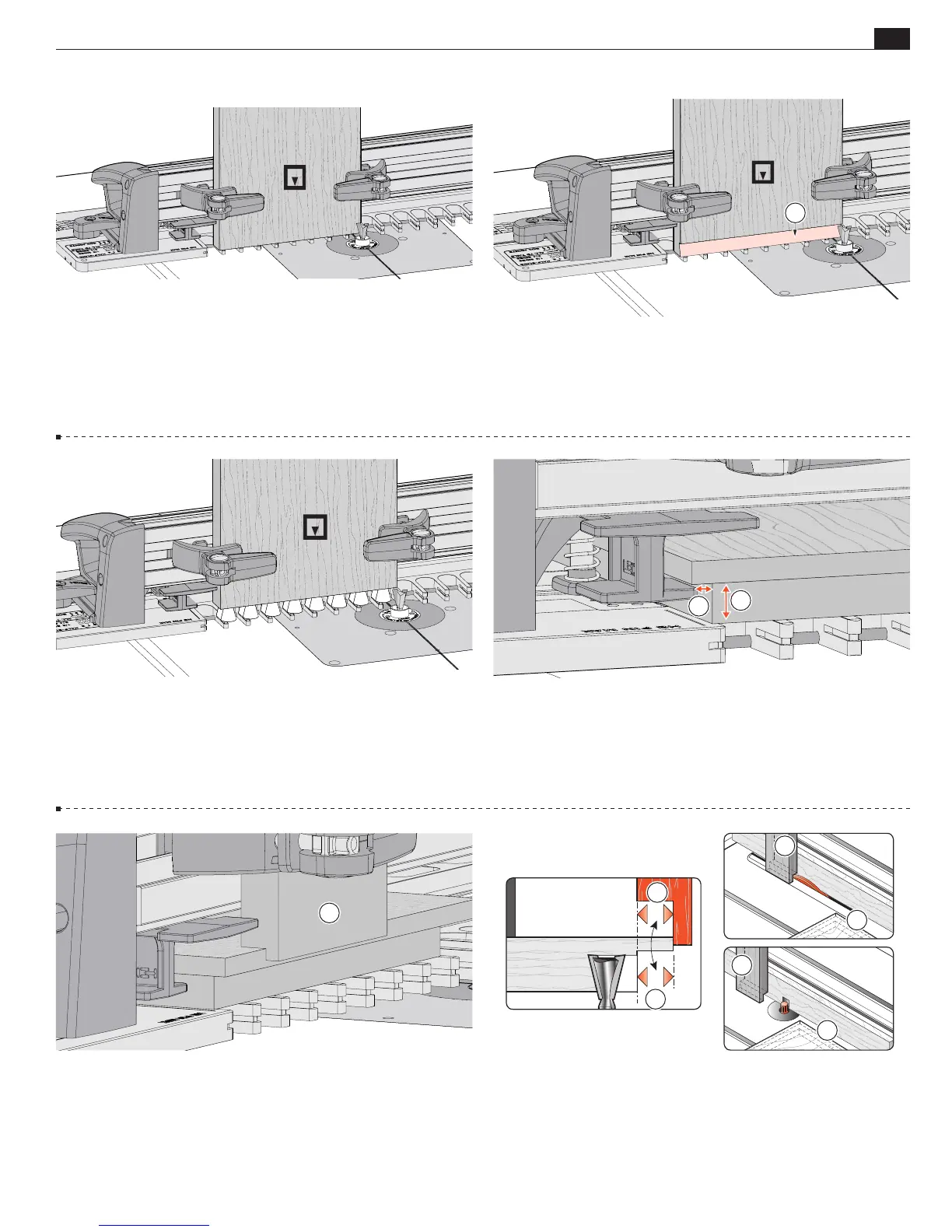

9-35 Left: The rabbet in the scrap limit stop

A

must be exactly

the same width as the rabbet on the drawer front

B

. An easy

and accurate way to make the limit stop, is to rabbet the end

vertically over the router bit or table saw blade

C

immediately

after horizontally machining the rabbet in the drawer front

D

.

A

9-32 Finish the tail board by routing in and out of each

template opening, keeping the guide bushing in contact with

all template finger surfaces. Remove the tail board.

Rabbeted Half-Blind Dovetails cont.

B

A

Loading...

Loading...