Do you have a question about the LEMKEN Solitair 9 and is the answer not in the manual?

Comprehensive safety guidelines for operating the implement, covering general precautions and specific risks.

Specific safety measures and considerations when the implement is operated in a trailed configuration.

Safety precautions and best practices for attaching and detaching implements.

Guidelines for safe mounting and dismounting of implements onto other machinery.

Critical safety information regarding the hydraulic system, including pressure and hose handling.

Safety advice and precautions related to the implement's tyres.

Essential safety rules and procedures to follow during maintenance operations.

Safety recommendations specific to the operation of seed drills.

Explanation of the purpose and importance of warning stickers on the implement.

Detailed explanation of the meaning and interpretation of various warning symbols.

Illustrates the specific locations of warning stickers on the Solitair implement.

Ensuring correct tractor tyre pressure and alignment for safe operation.

Procedure for adjusting lift rods to ensure proper implement attachment.

Adjusting check chains or sway blocks for implement stability.

Requirements for the tractor's drawbar when connecting the implement.

Calculations and considerations for maintaining safe tractor axle loads.

Formula and method for determining the minimum required front ballast.

Method for calculating the increase in rear axle load when the implement is attached.

Identification of necessary hydraulic spool valves and hose color codes.

Power supply requirements and voltage specifications for the implement.

Details on the electrical sockets needed for tractor connection.

Checks and adjustments for disc coulters and pressure rollers before initial operation.

Ensuring uniform pressure distribution on coulters and rollers.

Adjusting the frame height for single disc coulters.

Setting the position of the rear ground wheel relative to coulters.

Ensuring all stop slides are opened for operation.

Checking and preparing the seeding shaft seed wheels.

Adjusting bottom flaps based on the seed table settings.

Aligning track markers to the tractor's track width.

Verifying the functionality of various sensors via the on-board computer.

Testing the electric motors for tramline switch and seed wheel drive.

Adjusting tramline width to match tractor track width.

Setting the correct fan rotational speed for different seed types.

Encoding implement width and seed rate into the on-board computer.

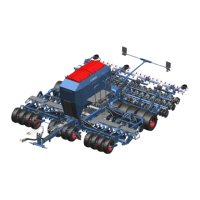

Using the Solitair with a chassis attached to the three-point linkage.

Attaching the Solitair to various LEMKEN soil cultivation implements.

Using the Solitair with semi-mounted LEMKEN soil cultivation implements.

Operating the Solitair in a trailed configuration with chassis and pole.

Operating the Solitair trailed with its own board hydraulic system.

Step-by-step guide for attaching the Solitair with chassis to a tractor's three-point linkage.

Procedures for safely detaching the Solitair from a tractor's three-point linkage.

Instructions for mounting the Solitair onto a mounted LEMKEN soil cultivation implement.

Procedures for safely dismounting the Solitair from a mounted implement.

Instructions for mounting the Solitair onto a semi-mounted LEMKEN soil cultivation implement.

Procedures for safely dismounting the Solitair from a semi-mounted implement.

Steps for correctly coupling the Solitair with chassis to a drawbar.

Procedures for safely uncoupling the Solitair from a drawbar.

How to fold the coulter bar in and out for transport or operation.

How to set the desired drilling depth for the seed.

Methods for adjusting coulter pressure for optimal soil engagement.

Adjusting coulter pressure using mechanical central adjustment.

Adjusting coulter pressure hydraulically from the tractor seat.

Adjusting the frame height for single disc coulter working position.

Setting the working depth for single disc coulters.

Detailed guide on seeding shafts, including seed wheel types and operation.

Table providing settings for various seed types, working widths, and seed rates.

Information on opening and operating slide plates for seed flow control.

How to adjust bottom flaps according to the seed table.

Procedures for emptying the implement's seed hopper.

Steps for regular cleaning of the seed dosage units.

Operation and adjustment of the tramline mechanism for creating seed paths.

When and how to perform a calibration test for accurate seeding.

Adjusting the rear ground wheel's position and sensor for accurate measurement.

Recommended fan speeds for different seed types and implement models.

How the cyclone separates dust and procedures for its cleaning.

Using slide plates to switch off specific working width sections.

Information on replacing worn double disc coulter scrapers.

Checking distributor heads and using plugs to close exits.

How to fill and close the seed hopper.

Procedure for disconnecting the agitator shaft using a securing pin.

General information about the standard equipment of track markers.

How to unlock, adjust, and operate the track markers.

Information on shear bolts protecting track markers from overload.

Overview of sensor positions and required adjustment for accurate measurement.

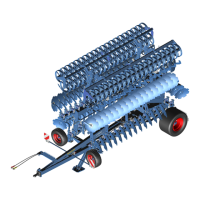

Fitting and adjusting single harrows for soil coverage.

Adjusting S-harrow position and pressure for optimal soil working.

Operation of the hydraulic lifting device for S-harrows.

Overview of available pre-emergence marker types and their fitting.

Operation and adjustment of hydraulic double-acting pre-emergence markers.

Operation and adjustment of hydraulic single-acting pre-emergence markers.

How to adjust the depth of the marking groove created by the markers.

Procedures for fitting and parking the Solitair chassis.

How to adjust and use track looseners to break soil compaction.

How to switch the working spot lights on and off using the control switch.

How seeding pipe control systems monitor seed flow and indicate alarms.

Table showing minimum and maximum allowed tyre operating pressures.

Details on the collecting box, its fuses, and the electrical connection plan.

Adhering to regulations for transporting the implement on public roads.

Table detailing key specifications for different Solitair 9 models.

Table detailing key specifications for Solitair 9 K and KA models.

List of part numbers, descriptions, and dimensions for spare parts.

Additional spare parts with their part numbers, descriptions, and dimensions.

Table detailing lubrication points and their required greasing frequency.

Guidelines for checking and tightening nuts and bolts during maintenance.

Regular checks for hydraulic hose damage and recommended replacement intervals.

Preparing seed wheels and bottom flaps for winter storage to prevent damage.

Greasing disc coulters and rollers to prevent rust and wear.

Safe procedures for cleaning the implement using a pressure washer.

How to check and clean the air tube before and after the season.

Regularly checking the function of end stops on mounted implements.

Information on the implement's noise level and recommended protective measures.

Notes on potential variations in equipment and the right to modify design.

Conditions for the guarantee period to commence, requiring product registration.

| Number of Rows | 24 - 96 |

|---|---|

| Transport Width | 3 m |

| Working Width | 3-12 m |

| Row Spacing | 12.5 / 15 cm |

| Weight | 4, 480 - 9, 300 kg (depending on equipment) |

Loading...

Loading...