Page 7

III - REFRIGERANT SYSTEM

A - Plumbing

Field refrigerant piping consists of liquid and suction lines

from the condensing unit (sweat connections) to theindoor

evaporator coil (flare or sweat connections). Use Lennox

L10 (flare) or L15 (sweat, non-flare) series line sets as

shown in table 1 or use field-fabricated refrigerant lines.

Separate discharge and suction service ports are pro-

vided outside the unit for connection of gauge manifold

during charging procedure.

TABLE 1

Model Liquid

Line

Suction

Line

L15

Line Sets

10ACC-018

10ACC-024

5/16 in*

(8 mm)

5/8 in

(16 mm)

L15-21

20 ft.- 50 ft.

(6m - 15m)

10ACC-030

10ACC-036

3/8 in

(10 mm)

3/4 in.

(19 mm)

L15-41

20 ft.- 50 ft.

(6m - 15m)

10ACC-042

10ACC-048

3/8 in

(10 mm)

7/8 in.

(22 mm)

L15-65

30 ft.- 50 ft.

(9m - 15m)

10ACC-060

3/8 in

(10 mm)

1-1/8 in.

(29 mm)

Field

Fabricated

*Field fabricate. See Corp. 9351-L9 Refrigerant Piping Nabual

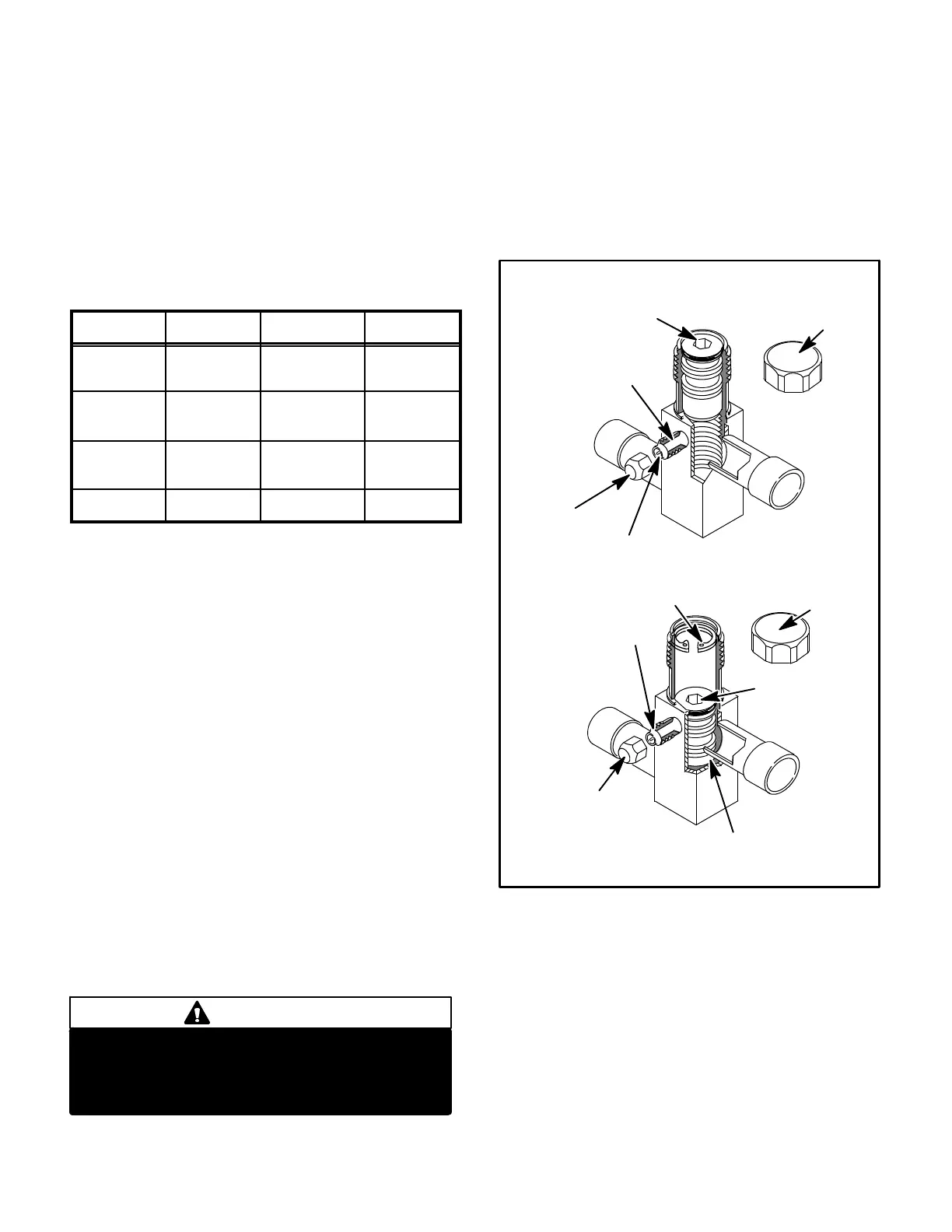

B - Service Valves

The liquid and suction line service valves (figures 10 and 11)

and gauge ports are accessible from outside the unit.

The valve is equipped with a service port. The service ports

are used for leak testing, evacuating, charging and checking

charge.Aschradervalveisfactoryinstalled. A service portcap

is supplied to protect the schrader valve from contamination

and serve as the primary leak seal.

NOTE-Always keep valve stem caps clean.

To Access Schrader Port:

1 - Remove service port cap with an adjustable wrench.

2 - Connect gauge to the service port.

3 - When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Liquid or Suction Line Service Valve:

1 - Remove stem cap with an adjustable wrench.

2 - Using service wrench and hex head extension (3/16 for

liquid line and 5/16 for suction line) back the stem out

counterclockwise until the valve stem just touches the

retaining ring.

3 - Replace stem captighten firmly. Tighten fingertight, then

tighten an additional 1/6 turn.

Do not attempt to backseat this valve. Attempts to

backseat this valve will cause snap ring to explode

from valve body under pressure of refrigerant.

Personal injury and unit damage will result.

DANGER

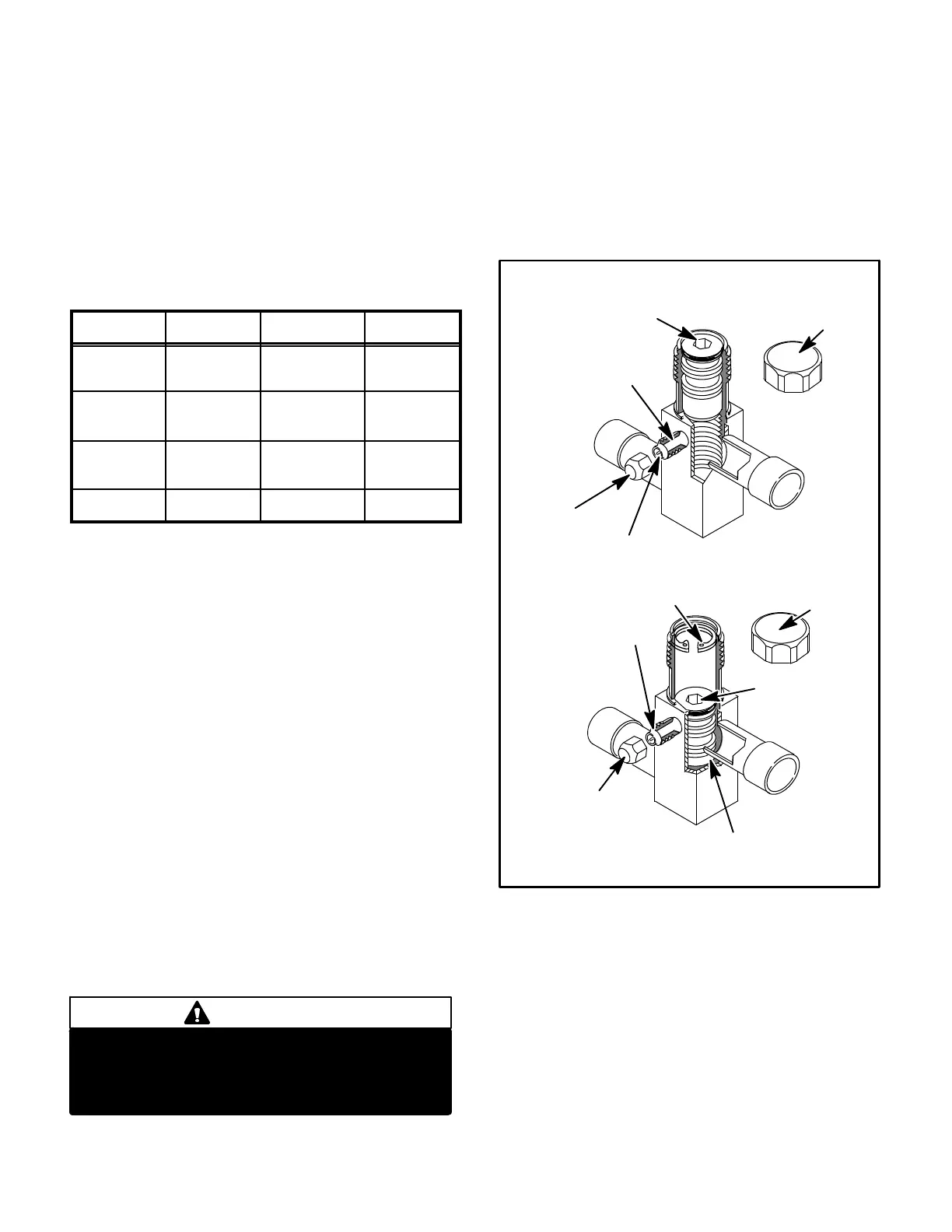

To Close Liquid or Suction Line Service Valve:

1 - Remove stem cap with an adjustable wrench.

2 - Using service wrench and hex head extension (3/16 for

liquid line and 5/16 for suction line), turn stem clockwise

to seat the valve. Tighten firmly.

3 - Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

FIGURE 10

LIQUID LINE SERVICE VALVE (VALVE OPEN)

SCHRADER

VALVE

SER-

VICE

PORT

SERVICE

PORT

CAP

INSERT HEX

WRENCH HERE

INLET (TO

INDOOR COIL)

OUTLET (TO

COMPRESSOR)

STEM CAP

SCHRADER VALVE OPEN

TO LINE SET WHEN VALVE

IS CLOSED (FRONT

SEATED)

SERVICE

PORT

SERVICE

PORT CAP

RETAINING RING

STEM CAP

OUTLET (TO

COMPRESSOR)

INSERT HEX

WRENCH HERE

LIQUID LINE SERVICE VALVE (VALVE CLOSED)

(VALVE FRONT

SEATED)

INLET

(TO INDOOR COIL)

Loading...

Loading...