Page 15

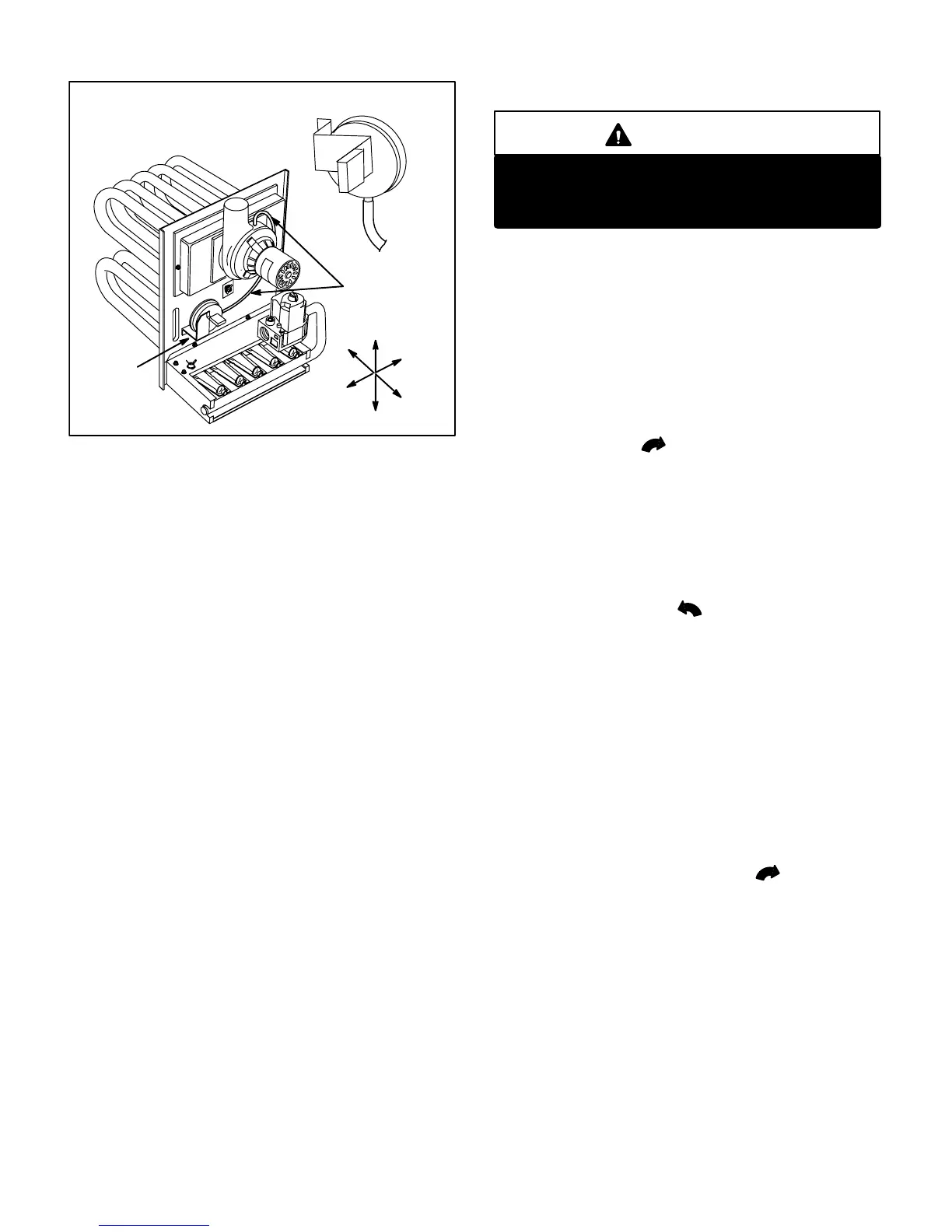

FIGURE 19

PROVE SWITCH

COMBUSTION AIR INDUCER

PROVE SWITCH

Normally Open

Closes on Negative Pressure

PROVE

SWITCH

Sensing Tube

Attaches to Top

Side Of Blower

Top

Bottom

Left

Right

Back

Front

On startĆup, the switch senses that the combustion air

blower is operating. It closes a circuit to the furnace control

when pressure inside the combustion air blower deĆ

creases to a certain set point. Set points vary depending

on unit size. The pressure sensed by the switch is relative

to atmospheric pressure. If the flue becomes obstructed

during operation, the switch senses a loss of negative

pressure (pressure becomes more equal with atmospherĆ

ic pressure) and opens the circuit to the furnace control

and gas valve. A bleed port on the switch allows dry relativĆ

ity air in the vestibule to purge switch tubing, to prevent

condensate build up. The switch also has an internal inline

orifice, designed to prevent nuisance shut downs due to

erratic vent pressure fluctuations.

The switch is factory set and is not field adjustable. It is a

safety shutĆdown control in the furnace and must not be

by-passed for any reason. If switch is closed or by-passed,

the control will not initiate ignition at start up.

II-PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

III-STARTĆUP

A-Preliminary and Seasonal Checks

1 - Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

2 - Check voltage at disconnect switch. Voltage must be

within range listed on the nameplate. If not, consult the

power company and have voltage condition corrected

before starting unit.

B-Heating StartĆUp

WARNING

Shock and burn hazard.

80UHG-1 units are equipped with a direct spark igniĆ

tion system. Do not attempt to light manually.

1 - STOP! Read the safety information at the beginning

of this section.

2 - Set thermostat to lowest setting.

3 - Turn off all electrical power to appliance.

4 - This appliance is equipped with an ignition device

which automatically lights the burners. Do not try to

light the burners by hand.

5 - Remove top access panel.

6 - White Rodgers 36E Gas Valve -- Switch lever to

OFF. See figure 15.

Honeywell VR8205 Gas Valve -- Turn knob on gas

valve clockwise to OFF. Do not force. See figĆ

ure 16.

7 - Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Close manual main shut-off valve to

the furnace. Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's instructions.

If you do not smell gas go to next step.

8 - White Rodgers 36E Gas Valve -- Switch gas valve lever

to ON.

Honeywell VR8205 Gas Valve -- Turn knob on gas

valve counterclockwise to ON. Do not force.

9 - Replace access panel.

10- Turn on all electrical power to unit.

11- Set thermostat to desired setting.

NOTE–When unit is initially started, steps 1 through 11

may need to be repeated to purge air from pilot line.

12- If the appliance will not operate, follow the instructions

To Turn Off Gas To Unit".

Turning Off Gas To Unit

1 - Set thermostat to lowest setting.

2 - Turn off all electrical power to unit if service is to be

performed.

3 - Remove access panel.

4 - Switch lever on White Rodgers gas valve to OFF; turn

knob on Honeywell valve clockwise to OFF. Do not

force.

5 - Replace access panel.

C-Safety or Emergency Shutdown

Turn off unit power. Close manual and main gas valves.

D-Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED" mode. Close

all gas valves (both internal and external to unit) to guaranĆ

tee no gas leak into combustion chamber. Turn off power

to unit. All access panels, covers and vent caps must be in

place and secured.

Loading...

Loading...