Page 10

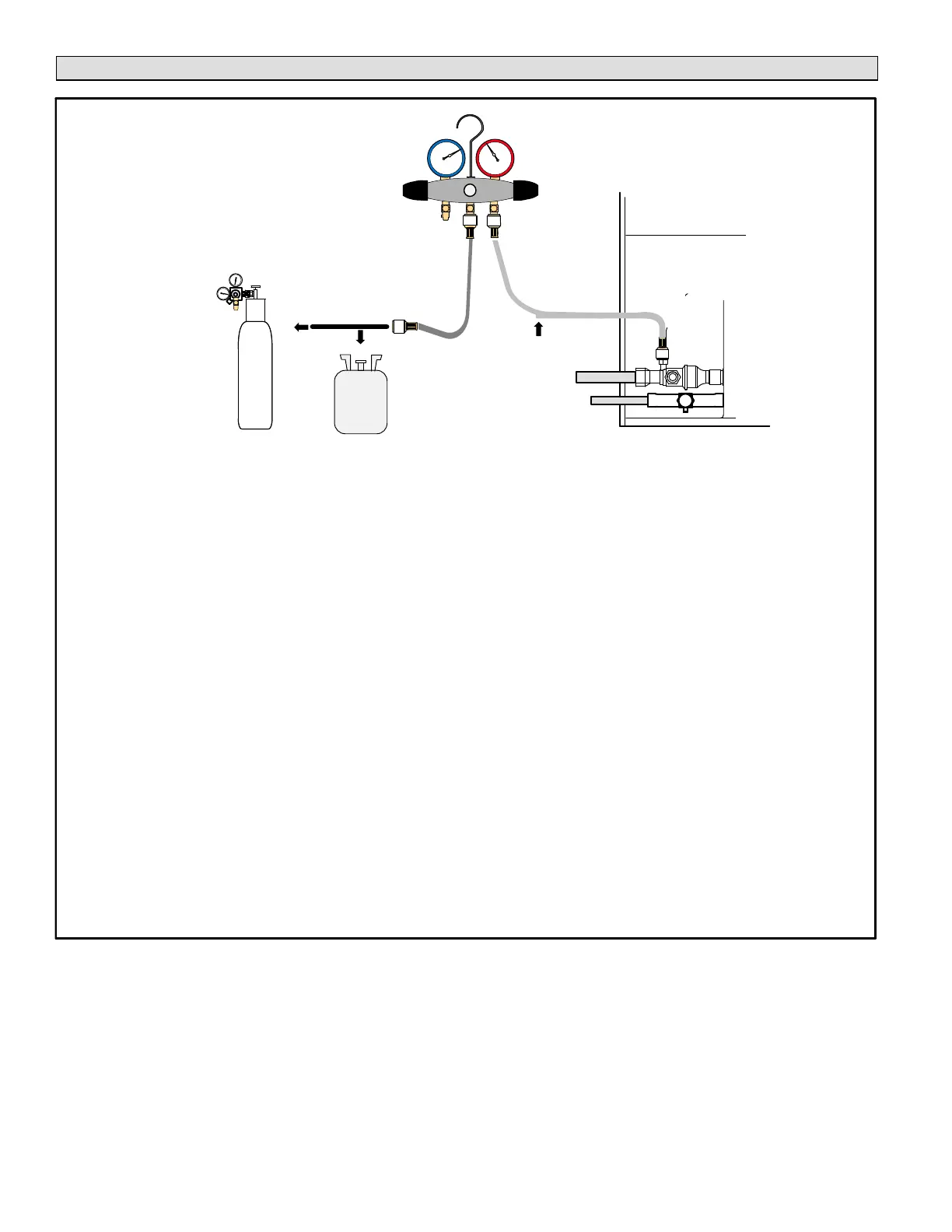

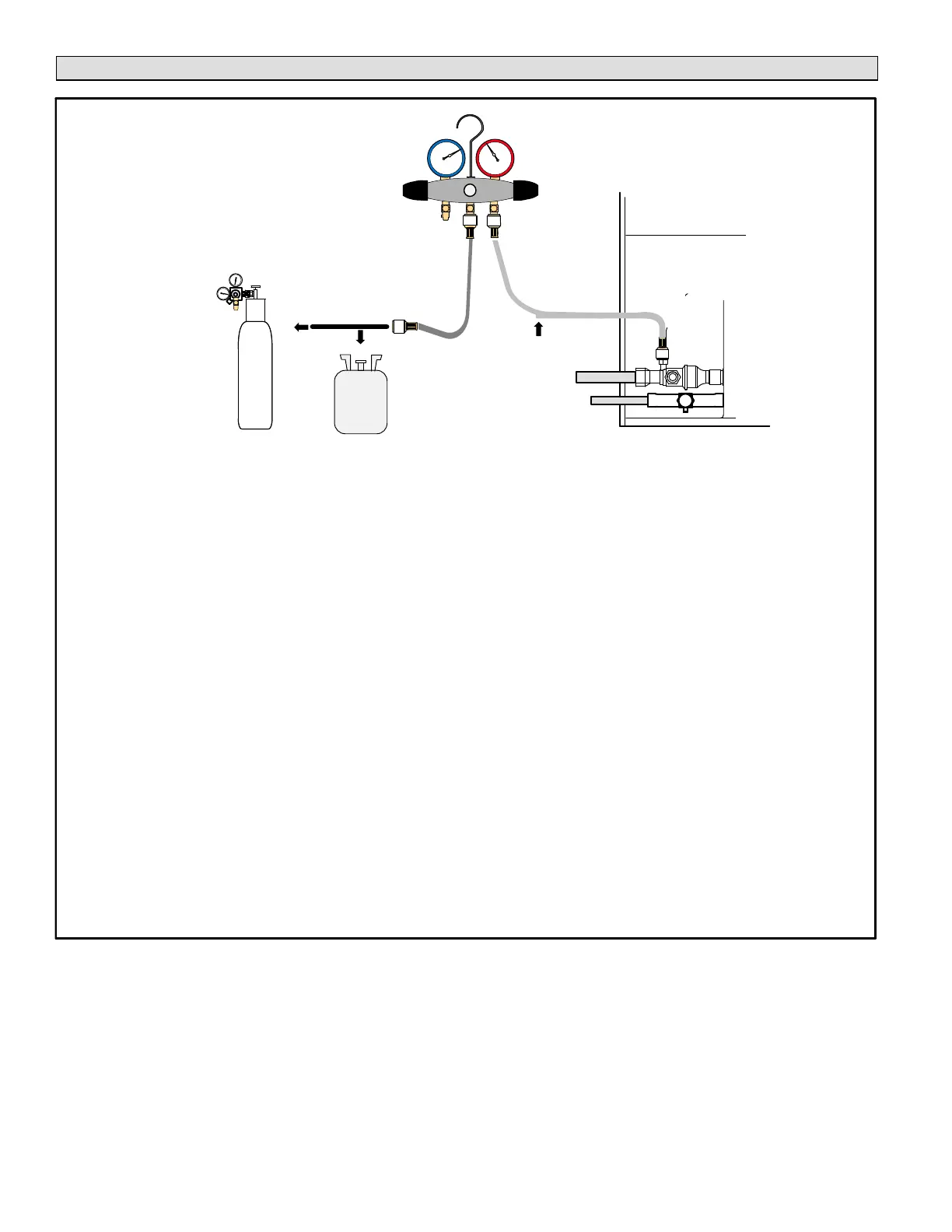

STEP 4 -- LEAK TEST AND EVACUATION

TO VAPOR

SERVICE VALVE

HFC-410A

MANIFOLD GAUGE SET

OUTDOOR UNIT

HIGHLOW

CONNECT GAUGE SET

A. Connect the high pressure hose of an HFC-410A manifold gauge set to the vapor valve service port.

NOTE — Normally, the high pressure hose is connected to the liquid line port. However, connecting it

to the vapor port better protects the manifold gauge set from high pressure damage.

B. With both manifold valves closed, connect the cylinder of HFC-410A refrigerant to the center port of

the manifold gauge set.

NOTE — Later in the procedure, the HFC-410A container will be replaced by the nitrogen container.

TEST FOR LEAKS

After the line set has been connected to the indoor and outdoor units, check the line set connections

and indoor unit for leaks. Use the following procedure to test for leaks:

A. With both manifold valves closed, connect the cylinder of HFC-410A refrigerant to the center port of

the manifold gauge set. Open the valve on the HFC-410A cylinder (vapor only).

B. Open the high pressure side of the manifold to allow HFC-410A into the line set and indoor unit.

Weigh in a trace amount of HFC-410A. [A trace amount is a maximum of two ounces (57 g) refriger

ant or three pounds (31 kPa) pressure.] Close the valve on the HFC-410A cylinder and the valve on

the high pressure side of the manifold gauge set. Disconnect the HFC-410A cylinder.

C. Connect a cylinder of nitrogen with a pressure regulating valve to the center port of the manifold

gauge set.

D. Adjust nitrogen pressure to 150 psig (1034 kPa). Open the valve on the high side of the manifold gauge

set in order to pressurize the line set and the indoor unit.

E. After a few minutes, open one of the service valve ports and verify that the refrigerant added to the

system earlier is measurable with a leak detector.

F. After leak testing, disconnect gauges from service ports.

1

2

A

B

NITROGEN

NOTE - Position

canister to deliver

liquid refrigerant.

FIGURE 7

38 of 44 B17-0056

01/19/2017

Loading...

Loading...