Page13

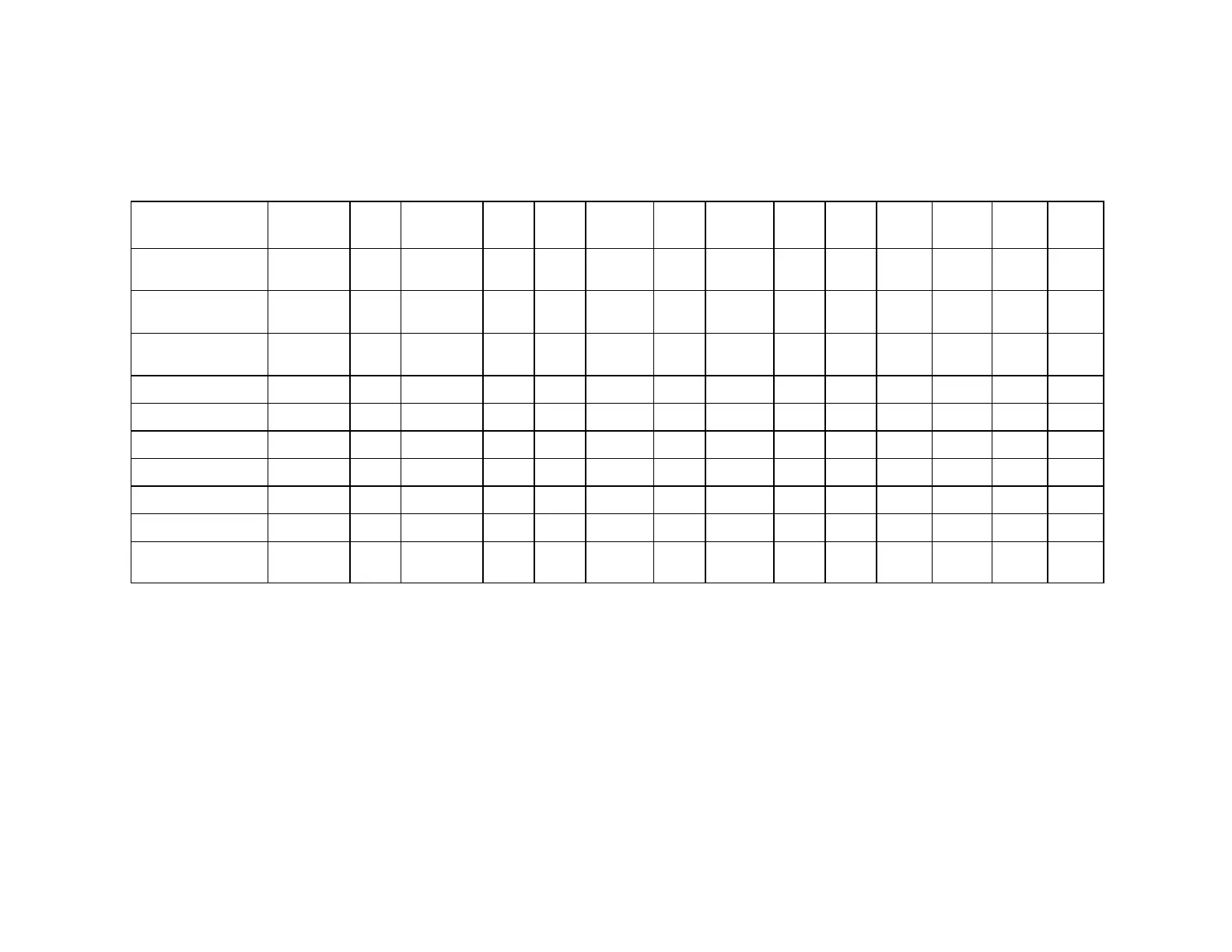

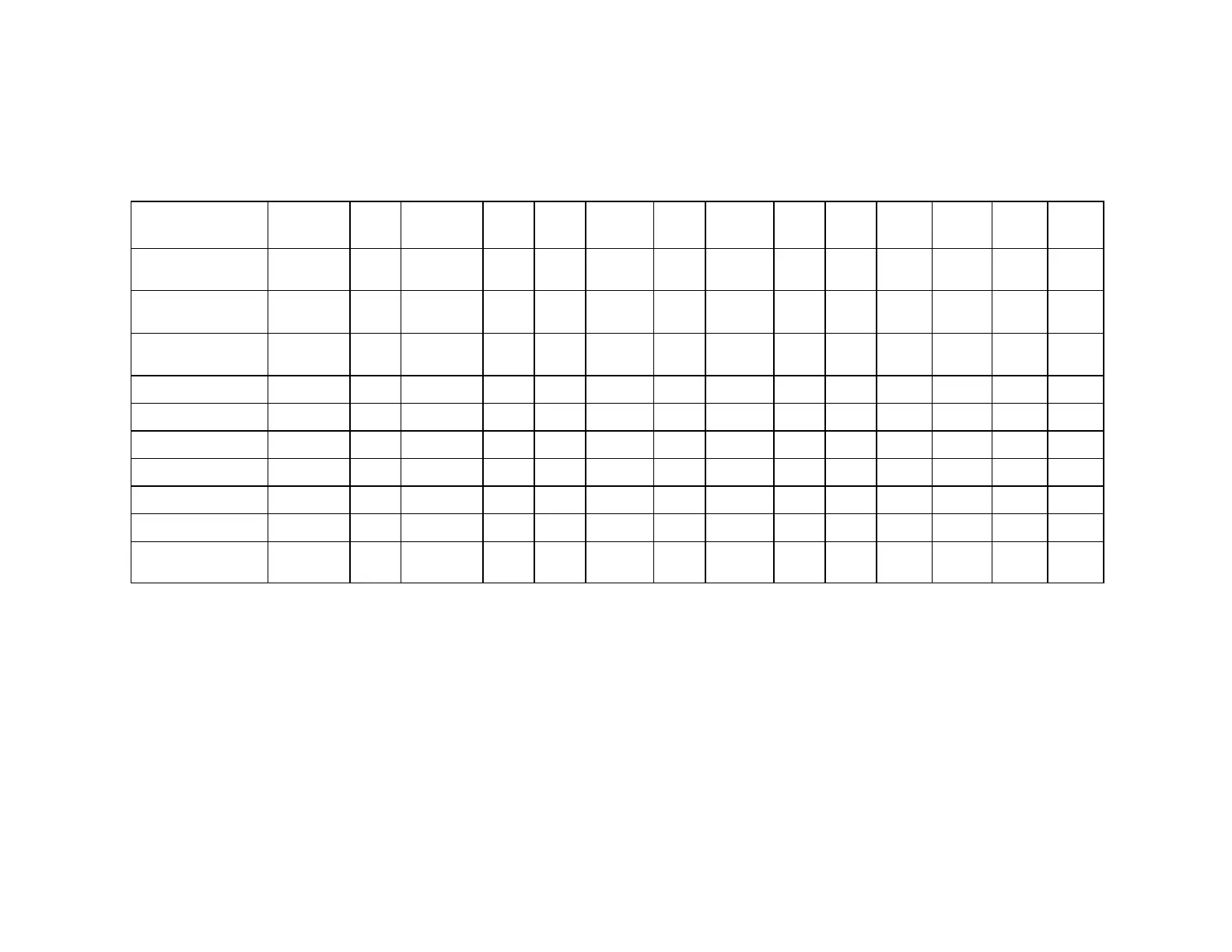

TABLE 3

12CHP060 with Variable Speed Motor

Mode of

Operation

Common W1 Common R O R R R Y G

Ramp

up

Ramp

up

Ramp

down

Ramp

down

25 Sec

After 7.5

Min

2 Sec 90 Sec

Motor Plug in

Terminals

Pin 1 Pin 2 Pin 3 Pin 5 Pin 9 Pin 10 Pin 11 Pin 12 Pin 14 Pin 15 CFM CFM CFM CFM

24 V motor wire Blue White Lt Blue Violet

Orang

e

Ta n Pink Red Yellow Green 82% 100% 94% 0%

Cooling X X X X X X X X X 1558 1900 1786 0

Continuous Fan X X X X X X X 590 590 590 0

Heat Pump X X X X X X X X 1558 1900 1786 0

Aux Heat (stage two) X X X X X X X X X 1558 1900 1786 0

Aux Heat (stage two) X X X X X X X X 1558 1900 1786 0

Emergency Heat X X X X X X X X 1558 1900 1786 0

Defrost Tempering

Heat

X X X X X X X X X X

NOTES:

Pins not used 4, 6, 7, 8, 13, 16

All motor times are approximate.

At start up, the motor runs at 82% of air flow for 7.5 minutes, then ramps up to 100%

At shut down, the motor runs at 94%of air for 60 seconds before a 30 second ramp off.

Continuous fan is 31% of total CFM−transition time from continuois fan to heat/cool air flow is 20 seconds.

SPEED CHANGES:

To increase COOLING CFM by 5%: Cut violet wire (PIN 5) to motor and tape off ends.

To increase HEATING CFM by 5%: Cut pink wire (PIN 11) to motor and tape off ends.

The above changes will increase the continuous fan speed to 620 CFM.

HUMIDITY CONTROL

The CFM of the motor can be reduced by 15% by wiring a standard humidity contol in series with the TAN (PIN 10) wire. The humidity control

must be closed when the humidity is below its setpoint and open when the humidity is above its setpoint. When the humidity control opens,

R is interupted to PIN 10 and the CFM is reduced 15% from full speed.

Loading...

Loading...