Page 9

I−APPLICATION

12GCS 2 through 5 ton (7.0 through 17.6kW) model units

are single packaged heat/cool units designed for outdoor

installation on a slab or rooftop.The units are available in

three cabinet sizes. 12CHP 2 through 5 ton (7.0 through

17.6kW) model units are available in three cabinet sizes and

are designed for outdoor installation on a slab or rooftop.

Electric heat can be factory or field installed if required.

12GCS/12CHP units are single−phase and residential only.

Refer to the Engineering Handbook for more specific ap-

plication data.

II−UNIT COMPONENTS

12GCS components are shown in figure 1. 12CHP compo-

nents are in figure 2. Component description will be broken

down into three categories: Control box, Gas and Cooling.

Some control box and cooling components will be shared by

both 12GCSmodel units and 12CHP model units. These com-

ponents will be identified as all models . Other components

will be identified as either GCS only" or CHP only"

A−Control Box Components

12GCS control box components are shown in figure 3. 12CHP

control box components are shown in figure 4.

1−Compressor Contactor K1 (all models)

K1 is a 24VAC to line voltage two pole double break contactor,

which energizes the compressor and condenser fan in re-

sponse to thermostat demand.

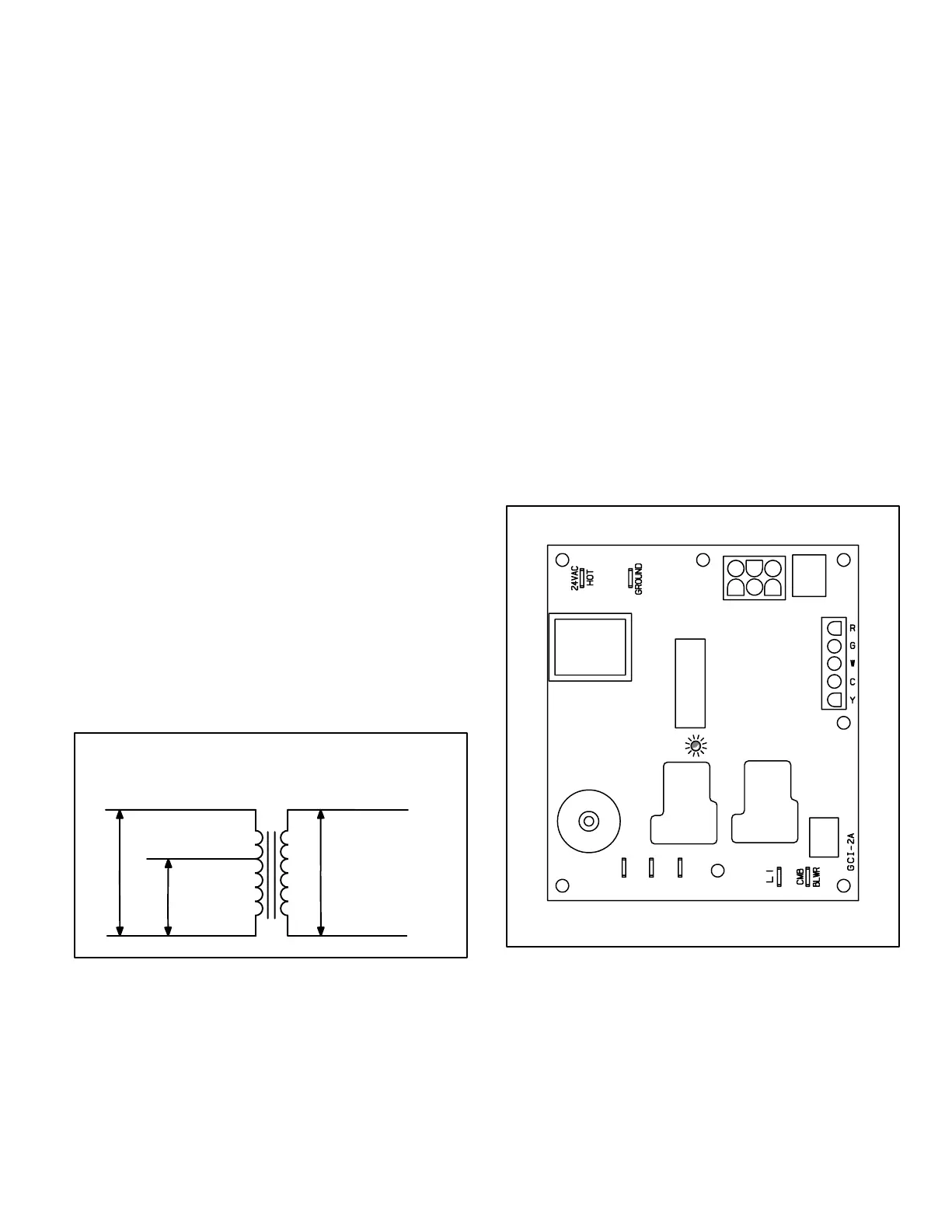

2−Control Transformer T1 (all models)

All 12GCS/12CHP series units use line voltage to 24VAC

transformer mounted in the control box. The transformer sup-

plies power to control circuits in the unit. Transformers use two

primary voltage taps as shown in figure 5.

FIGURE 5

240 VOLTS

208 VOLTS

PRIMARY

SECONDARY

208 / 240 VOLT TRANSFORMER

24 VOLTS

L1

L2

3−Dual Capacitor C12 (all models)

The compressor and condenser fan in the 12GCS/12CHP se-

ries units use permanent split capacitor motors. The capacitor

is located in the control box. A dual rated capacitor is used for

both the condenser fan motor and the compressor (see unit

wiring diagram per respective unit). The fan side and the com-

pressor side of the capacitor have different MFD ratings. See

side of capacitor for ratings.

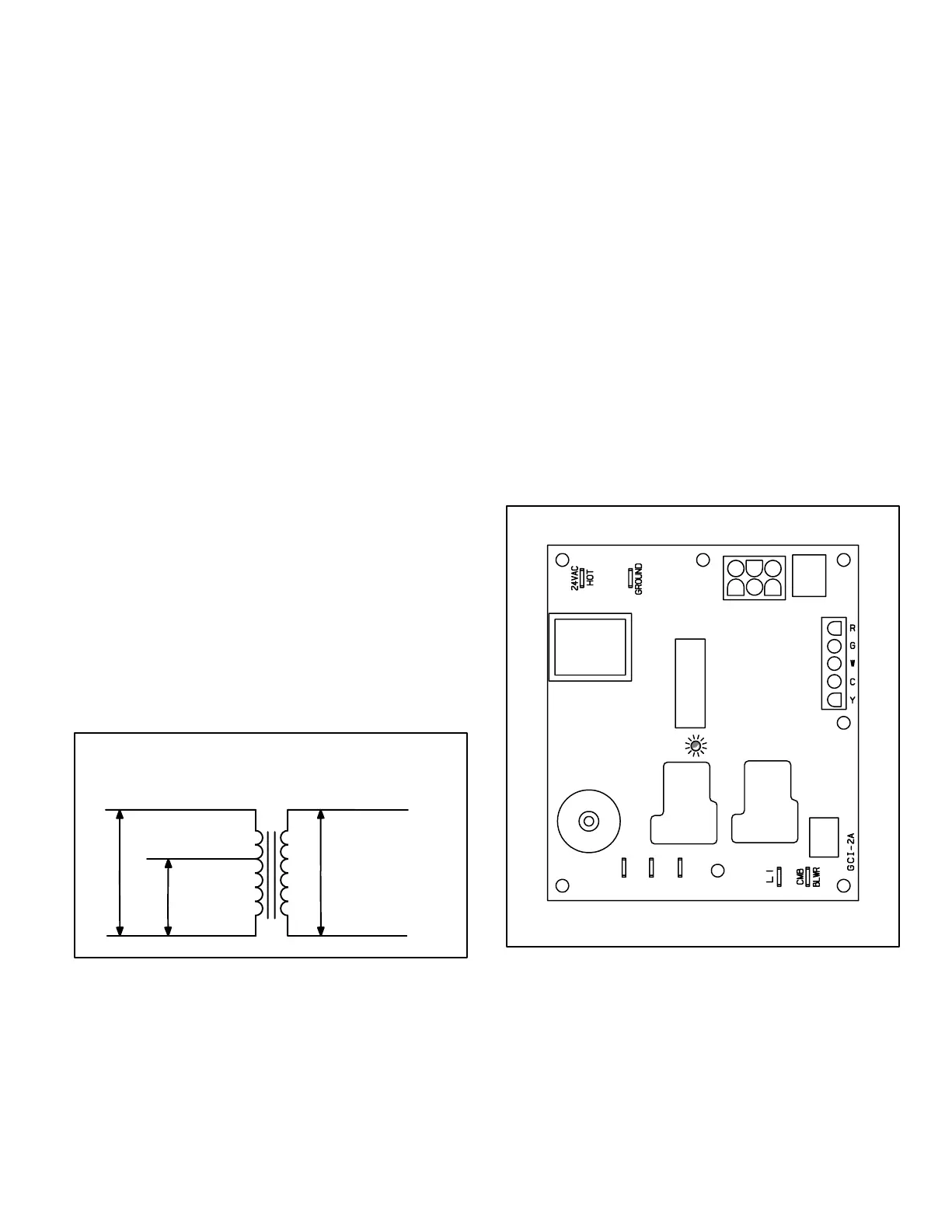

4−Ignition/Blower Control A3 (GCS only)

All 12GCS series units are equipped with an integrated ignition

/ blower board (A3) which controls ignition, safety circuits,

blower operation and fan off timing. See figure 6. Table 1

shows jack plug terminal designations.

Ignition control

All 12GCS units use direct spark ignition which is controlled by

an integrated ignition control board. On a call for heat the con-

trol monitors the combustion air prove switch. The control will

not begin the heating cycle if the prove switch is closed (by−

passed). Once the prove switch is determined to be open, the

combustion air inducer blower is energized. When the differen-

tial in the prove switch is great enough, the switch closes and a

30−second pre−purge begins. After the pre−purge period, the

gas valve opens and ignition (spark) is attempted for 10 sec-

onds. If the initial attempt for ignition fails, the sequence is re-

peated two more times. After a total of three failed attempts,

the board goes into Watchguard. During watchguard mode,

the board is de−energized for one hour. After one hour the con-

trol will repeat the ignition sequence. Watchguard may be

manually reset by breaking and remaking thermostat demand.

FIGURE 6

THERMOSTAT

CONNECTIONS

6 PIN PLUG 24VAC

LED DIAGNOSTIC

CONDITIONS

SPARK IGNITION

1

3

2

4

5

6

12GCS INTEGRATED CONTROL

BLOWER SPEED

TERMINALS

Safety Circuits

During the heating cycle the control monitors the safety circuits.

If the primary or secondary heating limits open, the control de−

energizes the gas valve and combustion air inducer blower

while the indoor blower remains energized. When the limit au-

tomatically resets the ignition sequence also resets.

If the rollout switch opens, the control de−energizes the gas

valve and the combustion air inducer blower. The unit will re-

main de−energized until the rollout switch is manually reset.

Loading...

Loading...