Page 13

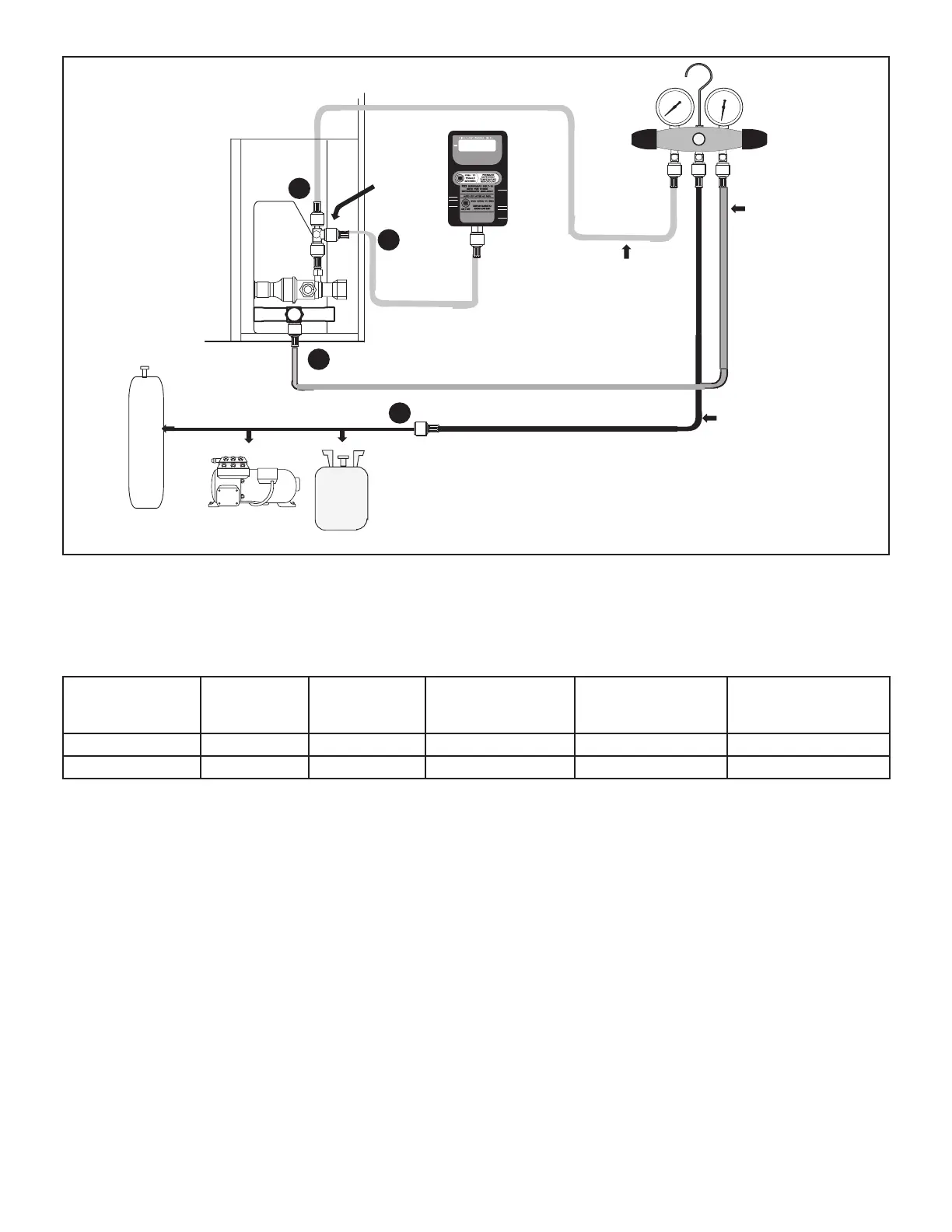

OUTDOOR UNIT

TO SUCTION

SERVICE VALVE

TO LIQUID

LINE SERVICE

VALVE

MICRON GAUGE

VACUUM PUMP

A34000 1/4 SAE

TEE WITH

SWIVEL

COUPLER

NITROGEN

50

MANIFOLD

GAUGE SET

HFC-410A

RECOMMEND MINIMUM

3/8” HOSE

A Connect low side of manifold gauge set with 1/4 SAE in-line tee to suction line

service valve

B Connect high side of manifold gauge set to liquid line service valve

C Connect micron gauge available connector on the 1/4 SAE in-line tee.

D Connect the vacuum pump (with vacuum gauge) to the center port of the

manifold gauge set. The center port line will be used later for both the

HFC-410A and nitrogen containers.

A

B

C

D

NOTE - Remove cores from service valves if not already done.

FIGURE 14

C-Charging

ELP units have a factory holding charge of 2 pounds of HFC-410A. Additional refrigerant will need to be added during

installation (table 4).

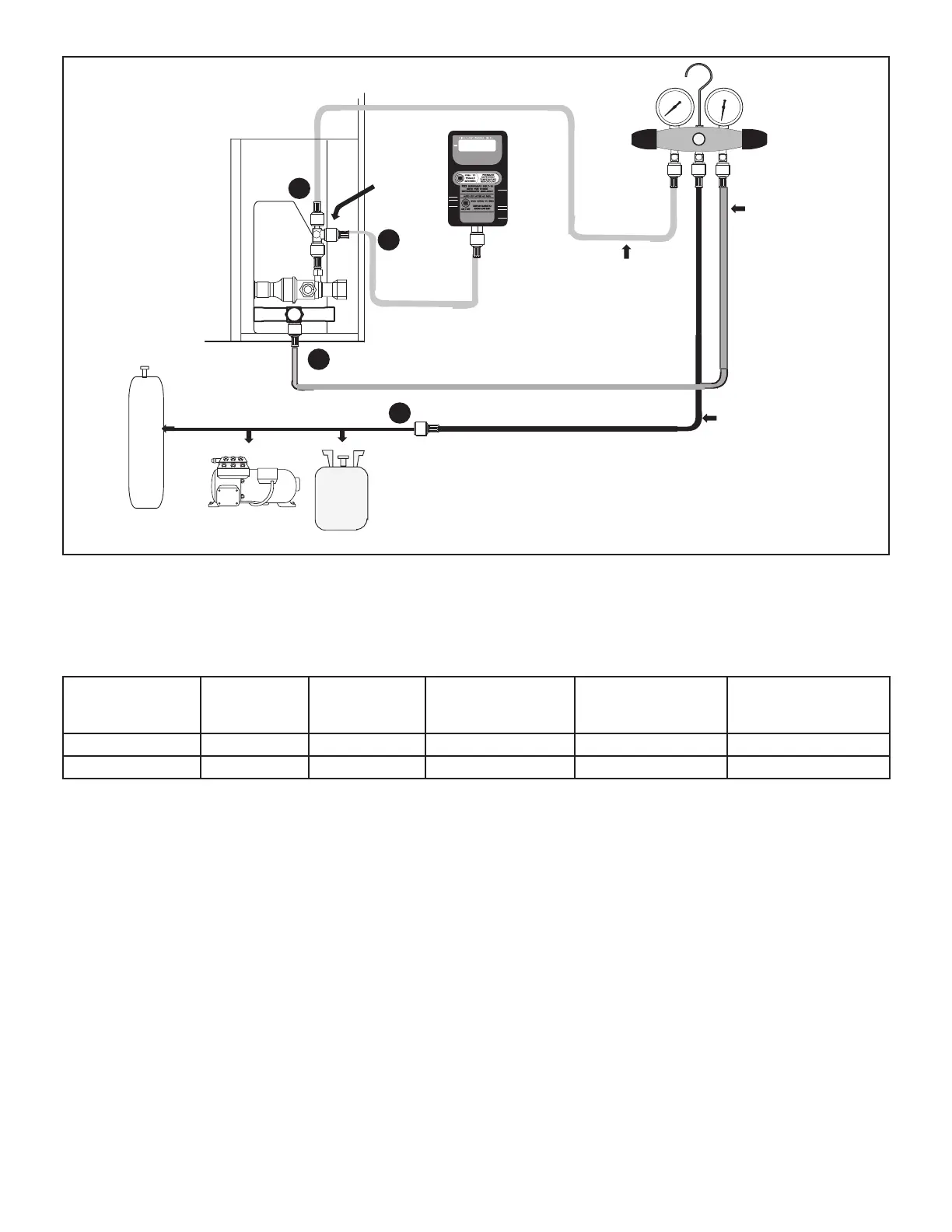

TABLE 4. Adding Refrigerant

Models

Total lbs –

Stage 1 with

25 ft line set

Liquid line

diameter

(inches)

Ounces adjustment

per ft of liquid line

Suction line diameter

(inches)

Ounces adjustment

per ft of suction line

ELP090S4S 23.25 5/8 1.5 1-1/8 0.2

ELP120S4S 32.5 5/8 1.5 1-1/8 0.2

To charge the system, use the following procedure:

1 - Measure actual length of liquid and vapor lines for

each circuit.

2 - Add refrigerant to each circuit based on measured

liquid and suction line lengths.

A - If the measured line length is greater than 25 feet,

add refrigerant (refer to table 2).

B - If the measured line length is less than 25 feet,

remove refrigerant (refer to table 2).

3 - Check normal operating pressures:

A - Connect a manifold gauge set to the service valves:

• Low pressure gauge to vapor valve service port

• High pressure gauge to liquid valve service port

B - Operate the system until pressures and

temperatures stabilize (5 minutes minimum).

C - Use a thermometer to measure the outdoor ambient

temperature.

D - If the outdoor temperature is greater than 65ºF (18ºC):

• Apply the outdoor ambient temperature to tables

4 or 5 to determine normal operating pressures.

Compare the normal operating pressures to the

pressures obtained from the connected gauges. If

liquid pressure is high, remove refrigerant from the

system. If liquid pressure is low, add refrigerant to

the system.

• Add or remove charge in increments.

• Allow the system to stabilize at least 5 minutes each

time refrigerant is added or removed.

• Minor variations in these pressures may be expect-

ed due to dierences in installations. Signicant dif-

ferences could mean that the system is not properly

charged or that a problem exists with some compo-

nent in the system.

Loading...

Loading...