Page 9

TABLE 2

REFRIGERANT LINE SIZES

ELP Unit Liquid Line Vapor Line

090 5/8" (16mm) 1-1/8" (29mm)

120 5/8" (16mm) 1-1/8" (29mm)

B-Service Valves

When servicing or repairing HVAC components, ensure

caps and fasteners are appropriately tightened. Table 3

lists torque values for typical service and repair items.

TABLE 3

Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.-lb. 11 NM

Sheet metal screws 16 in.-lb. 2 NM

Machine screws #10 28 in.-lb. 3 NM

Compressor bolts 90 in.-lb. 10 NM

Gauge port seal cap 8 ft.-lb. 11 NM

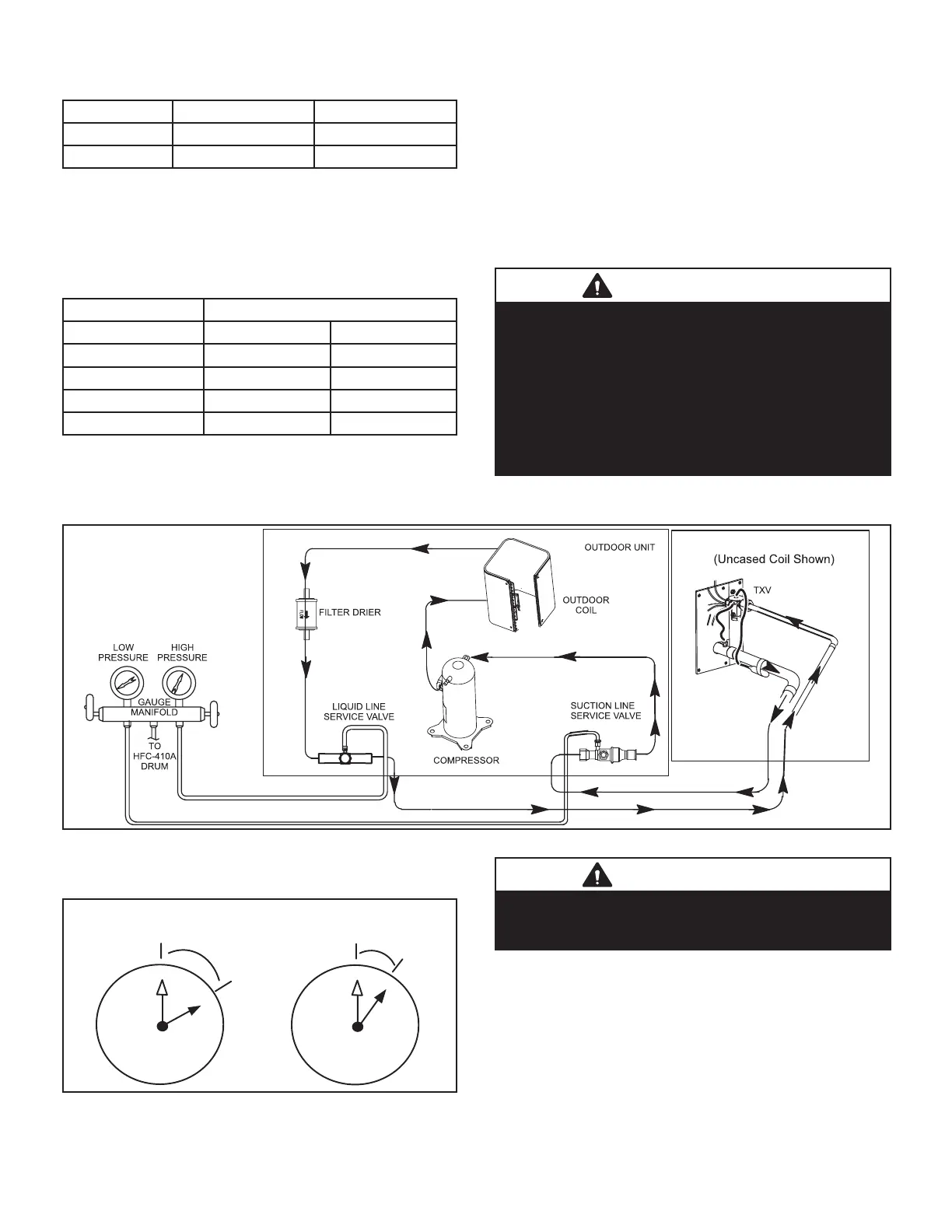

USING MANIFOLD GAUGE SETS

When checking the system charge, use a manifold gauge

set that features low-loss anti-blow back ttings. See g-

ure 9 for a typical manifold gauge connection setup.

Manifold gauge sets used with HFC-410A refrigerant sys-

tems must be capable of handling the higher system oper-

ating pressures. The gauges should be rated for use with

pressures of 0 - 800 on the high side and a low side of 30"

vacuum to 250 psi with dampened speed to 500 psi.

Gauge hoses must be rated for use at up to 800 psi of

pressure with a 4000 psi burst rating.

OPERATING SERVICE VALVES

The liquid and vapor line service valves are typically used

for removing refrigerant, ushing, leak testing, evacuating,

checking charge and charging.

IMPORTANT

Only use Allen wrenches of sucient hardness (50Rc

- Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory-torqued (from 9 ft-lbs

for small valves, to 25 ft-lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using an

Allen wrench rated at less than 50Rc risks rounding

or breaking o the wrench, or stripping the valve stem

recess.

FIGURE 9

Each valve is equipped with a service port which has a

factory-installed valve stem.

1

2

3

4

5

7

8

9

10

11

12

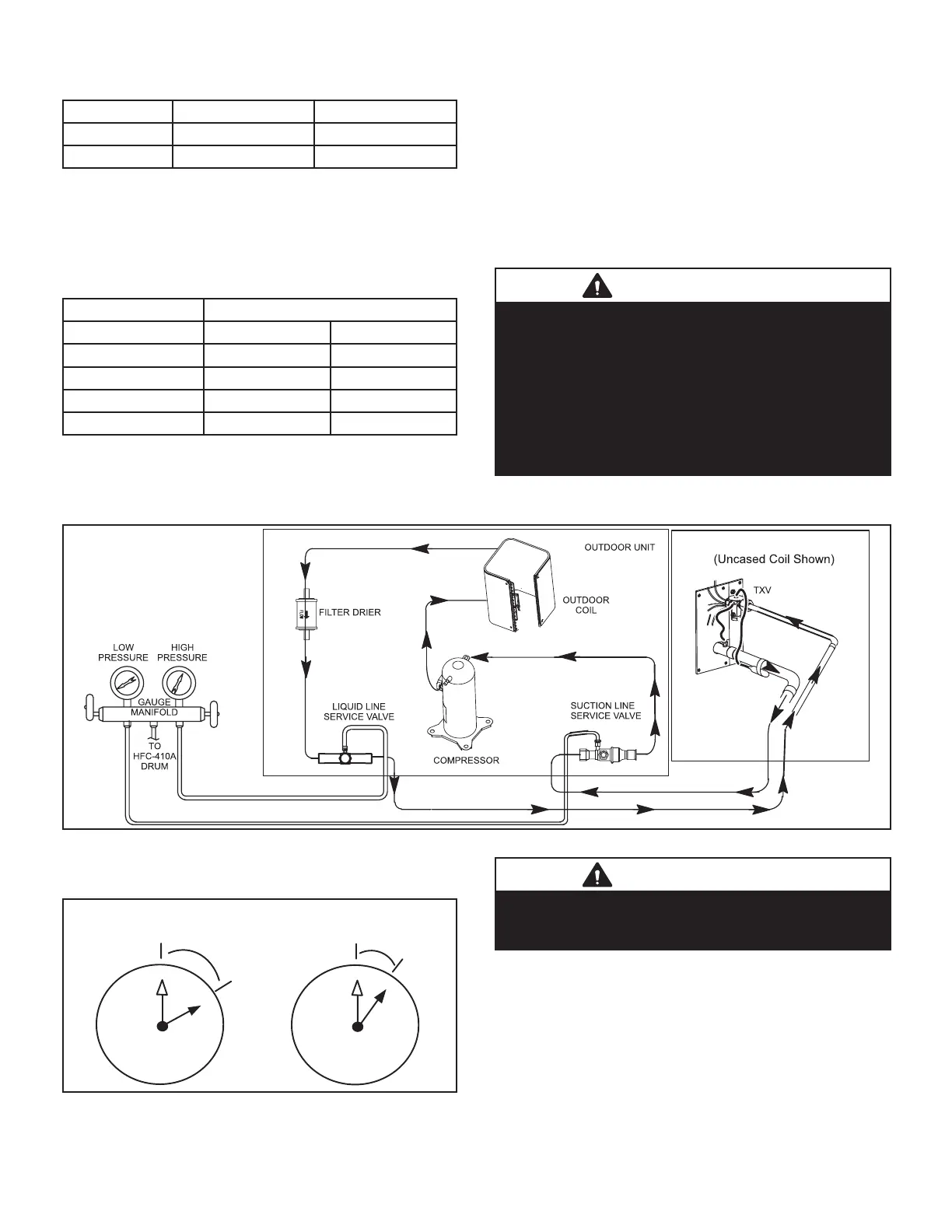

1/6 TURN

1

2

3

4

5

7

8

9

10

11

12

1/12 TURN

FIGURE 10

IMPORTANT

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and tted

snugly over the cap before tightening.

To Access Angle-Type Service Port:

A service port cap protects the service port core from con-

tamination and serves as the primary leak seal.

1 - Remove service port cap with an appropriately

sized wrench.

2 - Connect gauge to the service port.

Loading...

Loading...