VENTILATION : AIRFLOW BALANCING

FLEXYII_WSHP-IOM-0909-E Page 52

EXAMPLE

The unit used for this example is a FGM170ND with standard supply and return airflow configuration. It is also fitted with an

economiser and an electric heater type H.

It is fitted with 2 ADH450 L fans which curve is shown on page 36 and 2x 5.5 kW motors..

- Motor rpm: 1447 rpm

- cosϕ = 0.83

- Voltage = 400V

- Current = 9.00A (per fan)

P

mech fan

= V x I x √3 x cosϕ x η

mech motor

x η

Transmission

= 400 x 9.00 x √3 x 0.83 x 0.86 x 0.9 = 4.00kW

The unit is also fitted with 2 transmission kits 3.

- Fixed Fan pulley: 200mm

- Motor adjustable pulley type “8550” opened 4 turns from fully closed or measured distance between pulley end plates is

29.1mm: from table_1 it can be determined that each motor pulley has a diameter of 114.2mm

rpm

FAN

= rpm

MOTOR

x D

M

/ D

F

= 1447 x 114.2 / 200 = 826 rpm

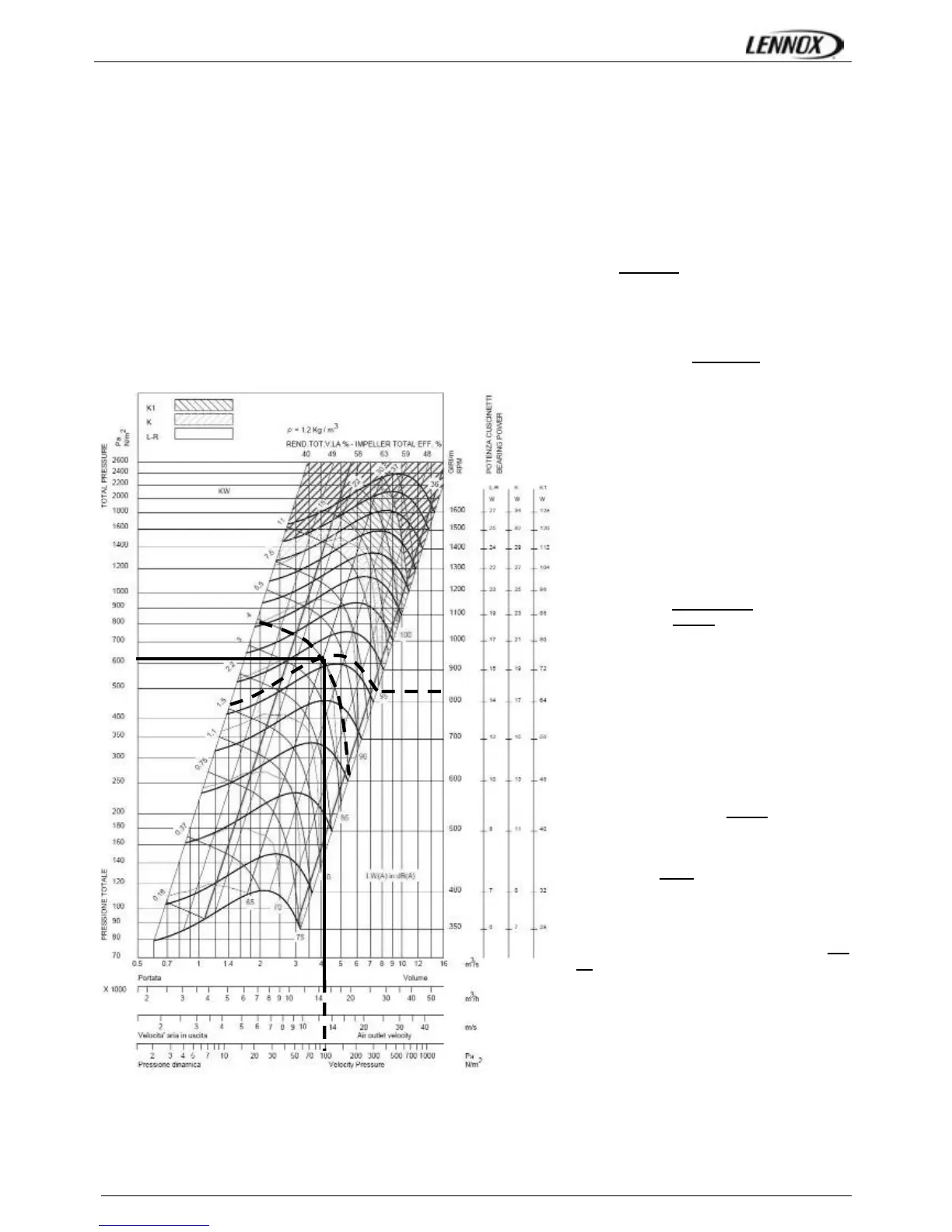

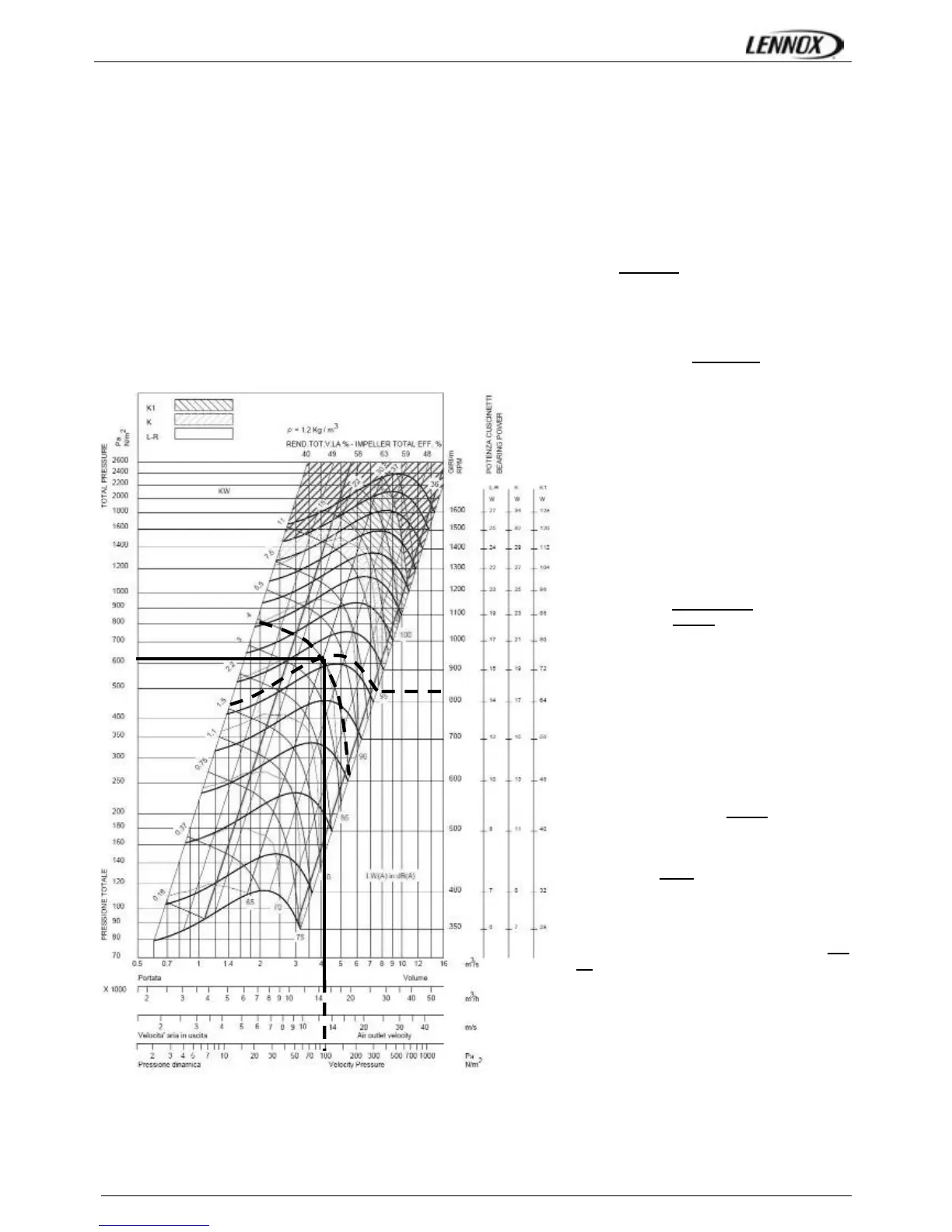

Using the fan curve, the operating point can

be located.

In order to facilitate the calculation, you

won’t make any mistake by considering

that the external static pressure available is

the one calculated with one fan providing

the half of the nominal flow (here

15000m3/h).

It can be determined that the fan is providing

approximately 15000 m3/h

with a total

pressure P

TOT

= 630 Pa

The pressure losses in the unit are the sum of

all pressure drops across the different parts of

a unit:

- Coil and filter (measured) = 89 Pa

- Inlet into the unit = 50 Pa

- Options = 16 Pa for economiser and 15

Pa for electric heater H

∆P = 89 + 16 + 15 +50 = 170 Pa

The dynamic pressure at 15000m

3

/h is given

at the bottom of the fan curve.

Pd = 81 Pa

The external static pressure available is

therefore

ESP = P

TOT

- Pd - ∆P

INT

=630 - 91 - 170 = 369

Pa

826rpm

630Pa

Loading...

Loading...