Page 13

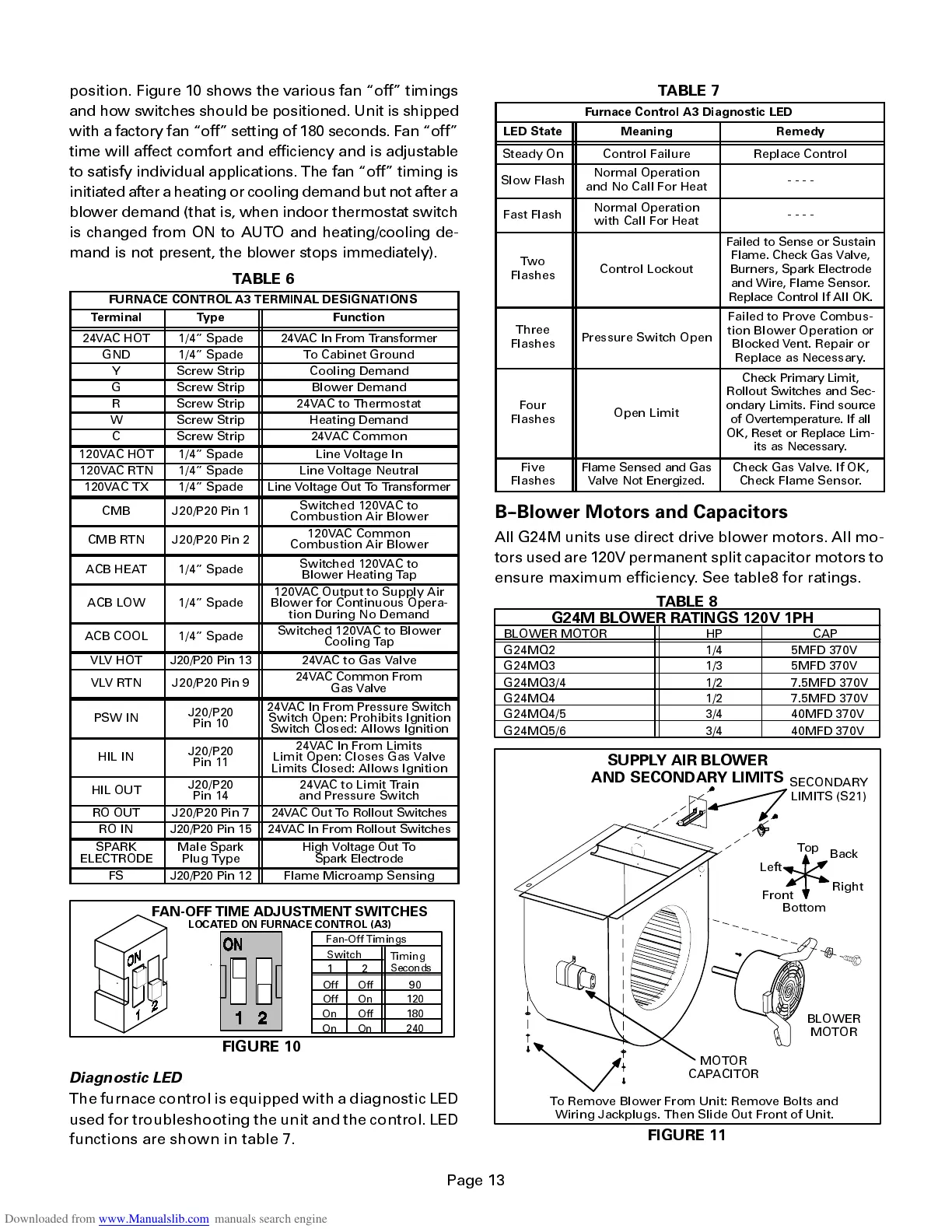

position. Fig u r e 10 show s th e va r i ous fan of f tim i ngs

and how switches should be positioned. Unit is shipped

with a factory fan off setting of 180 seconds. Fan off

time will affect comfo rt and efficiency and is adjustable

to satisfy individual applicatio ns. The fan off timing is

initiat ed after a heating or cooling demand but not after a

blower demand (that is, when indoor therm ostat switch

is changed from ON to AUTO and heating/cooling de-

mand is not present, the blower stops immediate ly).

TABLE 6

FURNACE CONTROL A3 TERMINAL DESIGNATIONS

Terminal Type Function

24VAC HOT 1/4 Spade 24VAC In From Transformer

GND 1/4 Spade To Cabinet Ground

Y Screw Strip Cooling Demand

G Screw Strip Blower Demand

R Screw Strip 24VAC to Thermostat

W Screw Strip Heating Demand

C Screw Strip 24VAC Common

120VAC HOT 1/4 Spade Line Voltage In

120VAC RTN 1/4 Spade Line Voltage Neutral

120VAC TX 1/4 Spade Line Voltage Out To Transformer

CMB J20/P20 Pin 1

Switched 120VAC to

Combustion Air Blower

CMB RTN J20/P20 Pin 2

120VAC Common

Combustion Air Blower

ACB HEAT 1/4 Spade

Switched 120VAC to

Blower Heating Tap

ACB LOW 1/4 Spade

120VAC Output to Supply Air

Blower for Continuous Opera-

tion During No Demand

ACB COOL 1/4 Spade

Switched 120VAC to Blower

Cooling Tap

VLV HOT J20/P20 Pin 13 24VAC to Gas Valve

VLV RTN J20/P20 Pin 9

24VAC Common From

Gas Valve

PSW IN

J20/P20

Pin 10

24VAC In From Pressure Switch

Switch Open: Prohibits Ignition

Switch Closed: Allows Ignition

HIL IN

J20/P20

Pin 11

24VAC In From Limits

Limit Open: Closes Gas Valve

Limits Closed: Allows Ignition

HIL OUT

J20/P20

Pin 14

24VAC to Limit Train

and Pressure Switch

RO OUT J20/P20 Pin 7 24VAC Out To Rollout Switches

RO IN J20/P20 Pin 15 24VAC In From Rollout Switches

SPARK

ELECTRODE

Male Spark

Plug Type

High V oltage Out To

Spark Electrode

FS J20/P20 Pin 12 Flame Microamp Sensing

FIGURE 10

FAN-OFF TIME ADJU

STMENT SWITCHES

LOCATED ON FURNACE CONTROL (A3)

Fan-Off Timings

Switch

12

Timing

Seconds

Off

OnOff

Off

OffOn

On On

120

90

180

240

Diagnostic LED

The furnace control is equipped with a diagnostic LED

used for troubleshooting the unit and the control. LED

functions are shown in table 7.

TABLE 7

Furnace Control A3 Diagnostic LED

LED State Meaning Remedy

Steady On Control Failure Replace Control

Slow Flash

Normal Operation

and No Call For Heat

----

Fast Flash

Normal Operation

with Call For Heat

----

Two

Flashes

Control Lockout

Faile d to Sense or Sustain

Flame. Check Gas V a lv e ,

Burners , Spark Electrode

and Wire, Flame Sensor.

Repla ce Control If All OK.

Three

Flashes

Pressure Switch Open

Failed to Prove Combus-

tion Blower Operation or

Blocked Vent. Repair or

Replace as Necessary.

Four

Flashes

Open Limit

Check Primary Limit,

Rollout Switches and Sec-

ondary Limits. Find source

of Overtemperature. If all

OK, Reset or Replace Lim-

its as Necessary .

Five

Flashes

Flame Sensed and Gas

Valve Not Energized.

Check Gas Valve. If OK,

Check Flame Sensor.

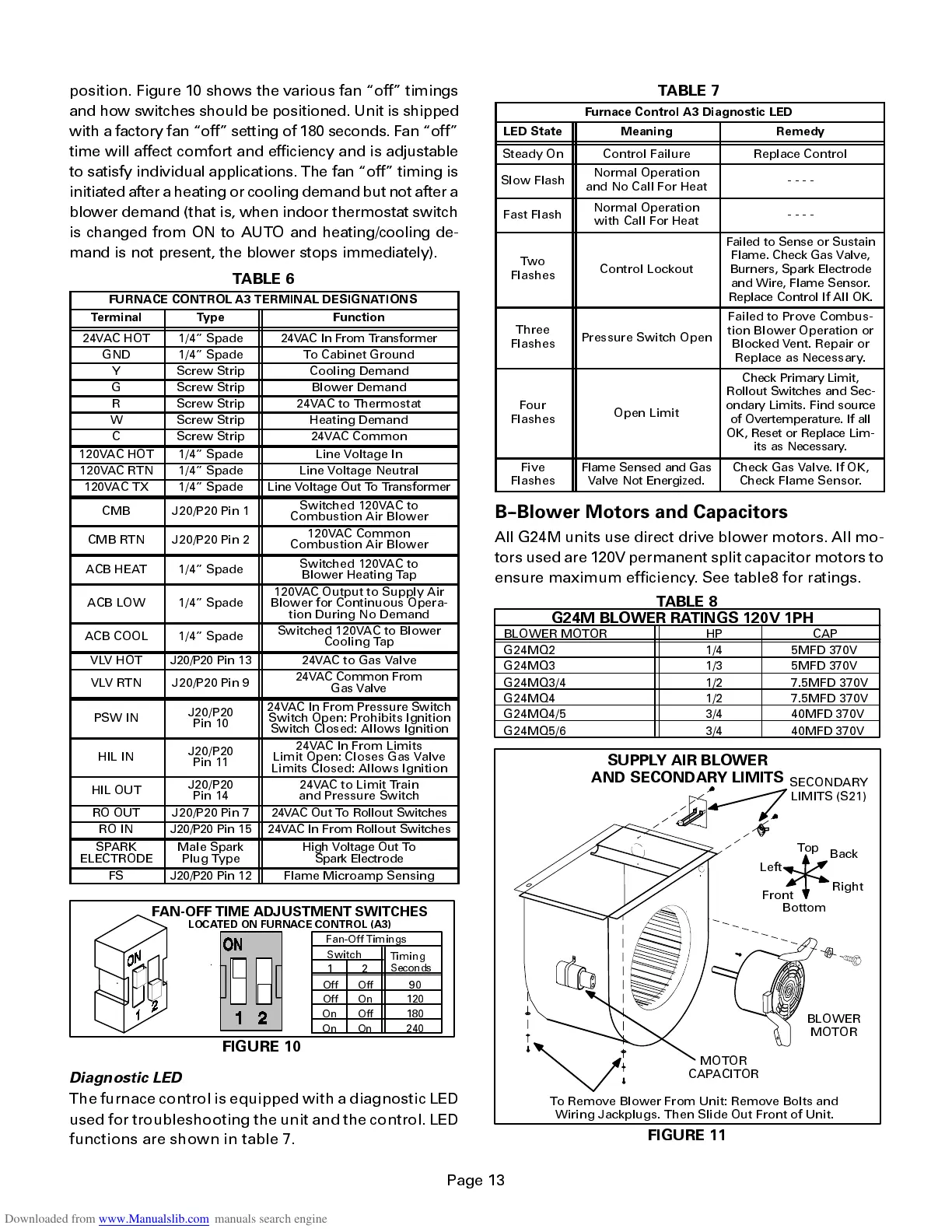

B--Blower Motors and Capacitors

All G24M units use direct drive blower motors. All mo-

tors used are 120V permanent split capacitor motors to

ensure maximum efficiency. See table8 for ratings.

TABLE 8

G24M BLOWER RATI

NGS 120V 1PH

BLOWER MOTOR HP

G24MQ2

G24MQ3

G24MQ3/4

CAP

1/2

1/3

1/4 5MFD 370V

5MFD 370V

7.5MFD 370V

G24MQ5/6

G24MQ4

G24MQ4/5

1/2 7.5MFD 370V

3/4 40MFD 370V

3/4 40MFD 370V

FIGURE 11

SUPPLY AIR BLOWER

AND SECONDARY LIMITS

Front

Bottom

Right

Left

Top

Back

BLOWER

MOTOR

To Remove Blower From Unit: Remove Bolts and

Wiring Jackplugs. Then Slide Out Front of Unit.

MOTOR

CAPACITOR

SECONDARY

LIMITS (S21)

Loading...

Loading...