Page 18

F- Proper Gas Flow

Furnace should operate at least 5 minutes before checkĆ

ing gas flow. Determine time in seconds for two revoluĆ

tions of gas through the meter. (Two revolutions assures

a more accurate time.) Divide by two and compare to time

in table 10 below. Adjust manifold pressure on gas valve

to match time needed.

NOTE- To obtain accurate reading, shut off all other

gas appliances connected to meter.

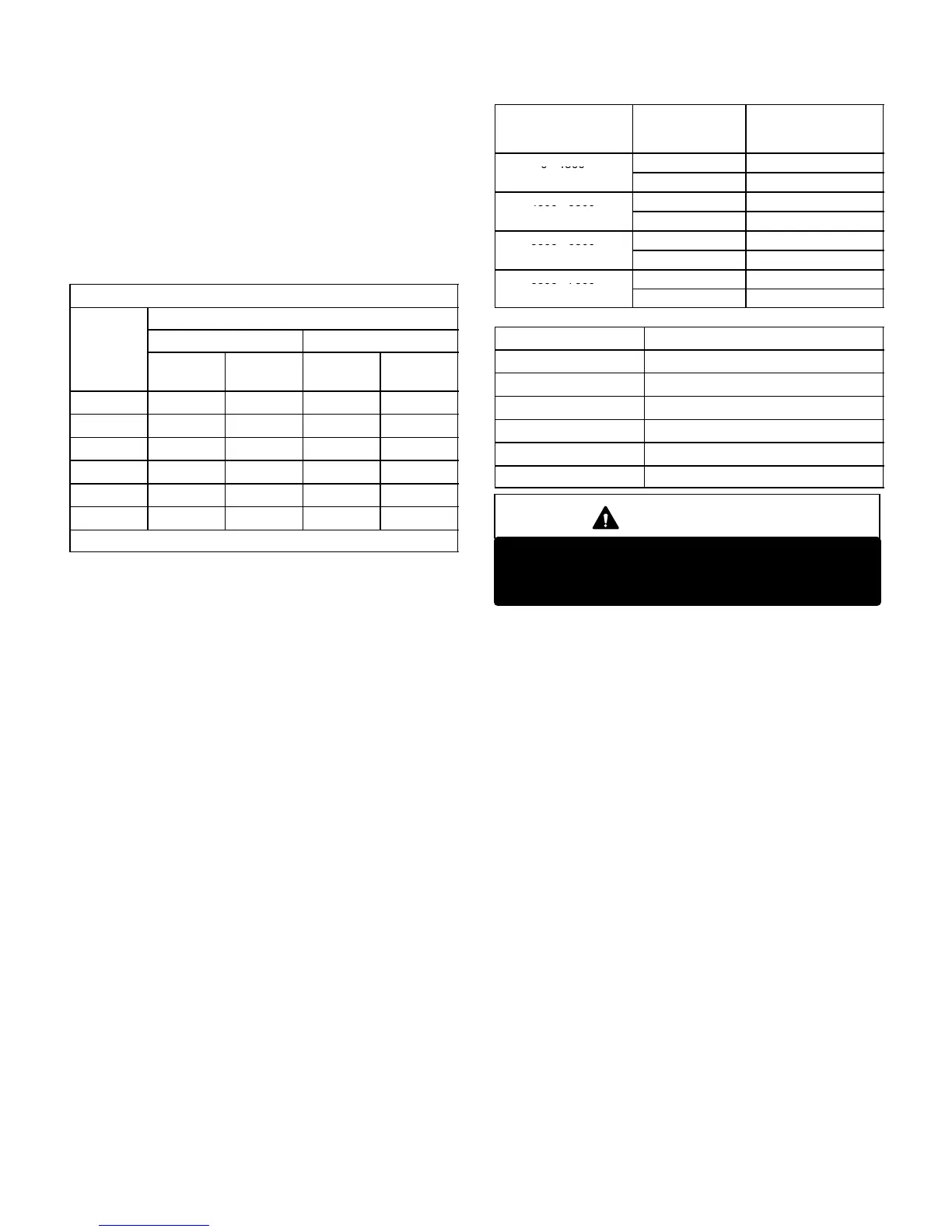

TABLE 10

GAS METER CLOCKING CHART

Seconds for One Revolution

G24M

Natural LP

Unit

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

-45 80 160 200 400

-60 60 120 150 300

-75 48 96 120 240

-100 36 72 90 180

-120 30 60 75 150

-140 26 52 64 128

Natural-1000 btu/cu ft LP-2500 btu/cu ft

NOTE- To obtain accurate reading, shut off all other

gas appliances connected to meter.

G-High Altitude Derate

NOTE-In Canada, certification for installation at altiĆ

tudes over 4500 ft. (1372m) above sea level is the jurisĆ

diction of the local authorities.

G24M-1 through -9 Models

This unit does not require gas pressure adjustment, or

pressure switch change when operating at elevations of 0

to 7500 ft. (0 to 2248m). Check gas line pressure with unit

firing. The minimum pressure as shown on the nameplate

for natural and propane gases must be maintained. No oriĆ

fice change is required.

NOTE-This is the only permissible field derate for this

appliance.

G24M-10 and -11 Models

Table 11 shows manifold pressure settings for installations

at different altitudes. Refer to table 12 for pressure switch

replacement for models at elevations of 4500 feet (1372m)

and greater.

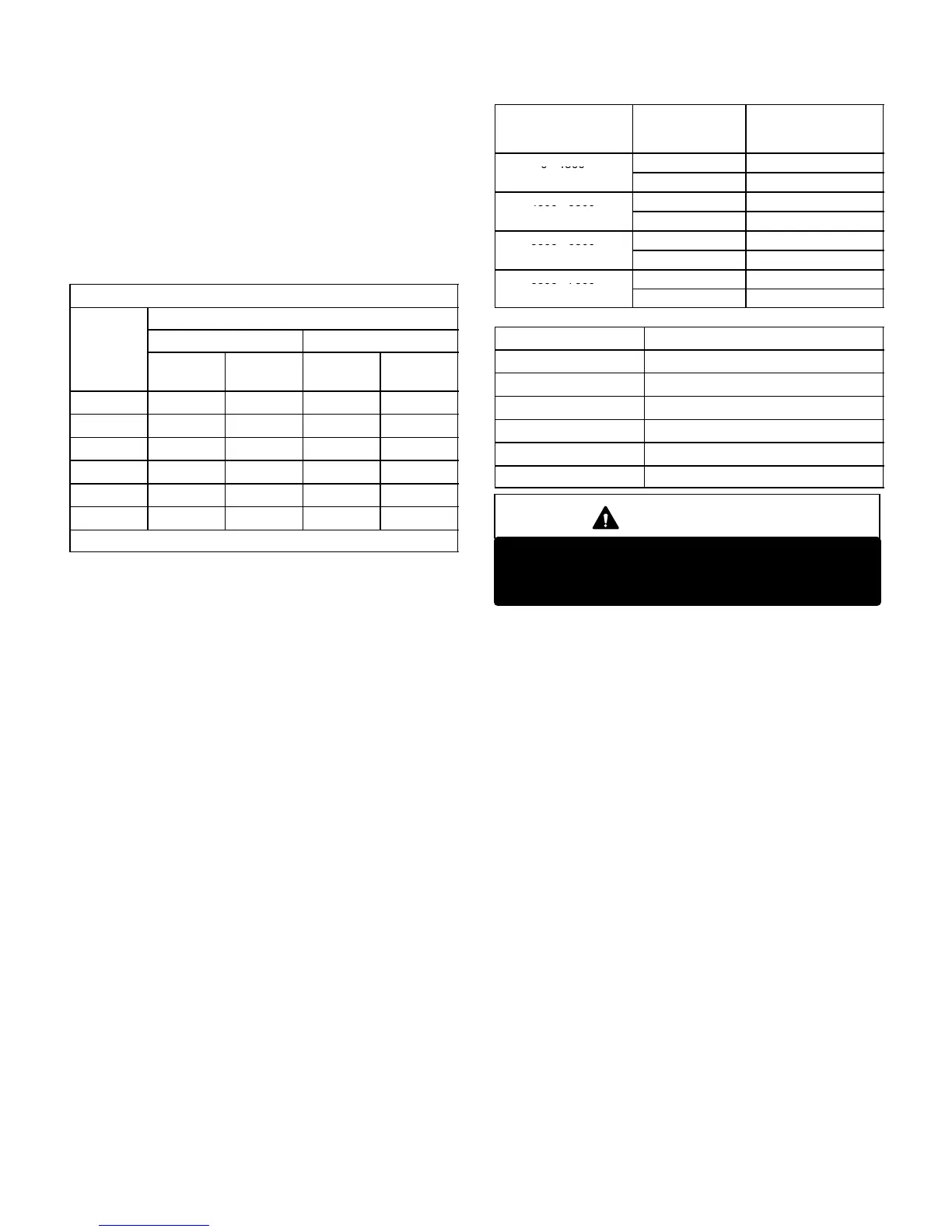

TABLE 11

ALTITUDE

feet (m)

GAS FUEL

MANIFOLD

PRESSURE

in. W.C. (kPa)

0 - 4500

Natural 3.5 (0.87)

(0 - 1372)

Propane/LP 9.5 (2.36)

4500 - 5500

Natural 3.4 (0.86)

(1372 - 1676)

Propane/LP 9.2 (2.29)

5500 - 6500

Natural 3.3 (0.82)

(1676 - 1981)

Propane/LP 8.9 (2.21)

6500 - 7500

Natural 3.2 (0.80)

(1372 - 2286)

Propane/LP 8.6 (2.14)

TABLE 12

Unit Model Pressure Switch Part Number

G24M-45 No Change

G24M-60 No Change

G24M-75 88J8001

G24M-100 18L2401

G24M-120 18L2401

G24M-140 No Change

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

H-Flame Signal

A microamp DC meter is needed to check the flame signal

on the primary ignition control.

Flame (microamp) signal is an electrical current which

passes from the furnace control through the sensor elecĆ

trode during unit operation. Current passes from the senĆ

sor through the flame to ground to complete a safety cirĆ

cuit.

To Measure Flame Signal:

1 - Place meter in series between furnace control and

sensor wire. Connect the positive (+) lead of meter to

the ignition control sensor connection and the negaĆ

tive (-) lead of the meter to the sensor wire. See figure

21.

2 - Set thermostat for a heating demand and check flame

signal with unit operating. For G24M series with a RAM

control, a reading of 1 to 5 microamps DC should occur.

The furnace control must see at least 1.0 microamps in

order to keep the gas valve energized. G24M units with

the SureLight control should read 0.7 microamps or

more.

Loading...

Loading...