Page 9

Downflow Applications

The Lennox G24M furnace is shipped in the upflow config

uration and must be converted for downflow installation.

Refer to figure 6 and the following steps to convert the unit

for downflow installation:

1 - Place unit on its back and remove access panel.

2 - Disconnect wire harness jackplugs from control

board.

3 - Disconnect sensor lead from control board.

4 - Remove four screws securing cabinet top cap to cabi

net.

5 - Remove four screws holding heat exchanger assem

bly in place. Slide heat exchanger out through top of

cabinet.

6 - Rotate heat exchanger 180

o

and slide back into cabi

net through top. Resecure using four screws.

7 - Remove four screws securing cabinet bottom piece

to cabinet. Replace with cabinet top cap.

8 - Use four screws to install cabinet bottom piece where

cabinet top was.

9 - Reconnect sensor lead to control board.

10- Reconnect wire harness jackplugs to control board.

11- Replace unit access panel.

12- Use cord clip located on right side of furnace to

hold wiring away from hot surfaces in heating

compartment. Install two #10 sheet metal screws in

cabinet top to provide a better air seal.

In downflow applications, the unit can be installed in three dif

ferent ways: on noncombustible flooring, on combustible

floor using an additive base, or on a reverseflow cooling cab

inet. Do not drag unit across floor.

Allow clearances to combustible materials as indicated on

unit rating plate. Minimum clearances for closet or alcove

installations are shown in figure 7.

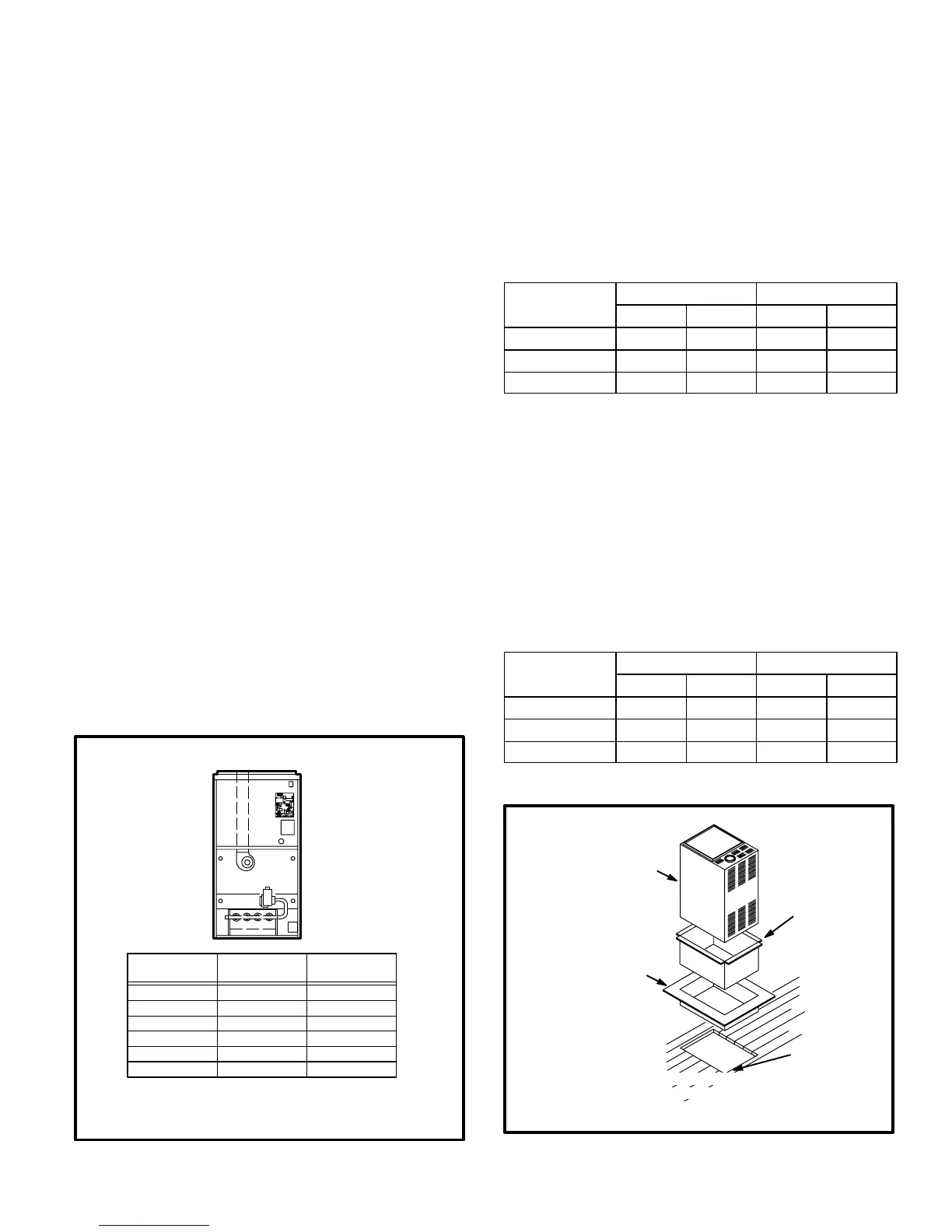

DOWNFLOW INSTALLATION CLEARANCES

VENT

CONNECTOR

TYPE C TYPE B1

TOP 1" (25mm) 1" (25mm)

*FRONT 2" (51mm) 2" (51mm)

BACK 00

SIDES 00

VENT 6" (152mm) 1" (25mm)

TOP

BOTTOM

RIGHT

SIDE

LEFT

SIDE

NC - Non-combustible floor

*Front clearance in alcove installation must be a min. of 24" (610mm)

for front service access.

**With additive base on combustible floor.

FLOOR NC** NC**

(60 Hz. only)

FIGURE 7

A separate downflow filter kit is available for use in down

flow applications.

A-Installation on Non-Combustible Flooring

1 - Cut floor opening keeping in mind the clearances

listed on the unit rating plate. Also, keep in mind gas

supply and electrical supply, vent connections and

sufficient installation and service clearances. See

table 1 for correct floor opening size.

TABLE 1

NONCOMBUSTIBLE FLOOR OPENING

Front to Rear Side to Side

UNIT

in mm in mm

G24M-45/60/75 19-3/4 502 15-1/4 388

G24M-100/120 19-3/4 502 18-3/4 477

G24M-140 19-3/4 502 21-1/2 546

NOTE - Floor opening dimensions listed are 1/4" (6mm) larger than unit

openings.

2 - Flange warm air plenum and lower into opening.

3 - Set unit over plenum.

4 - Check to see that an adequate seal is made.

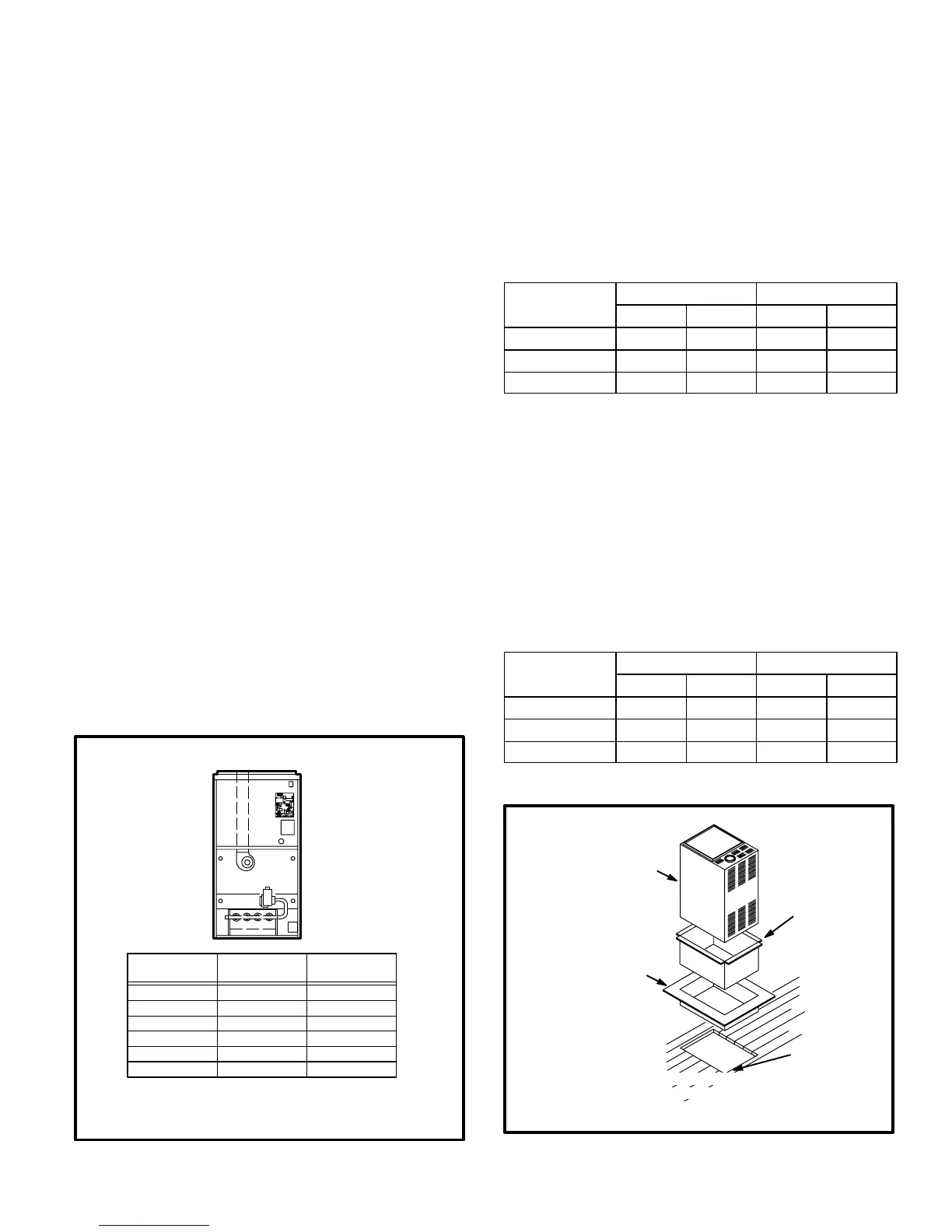

B-Installation on Combustible Flooring

1 - When unit is installed on a combustible floor, an addi

tive base (ordered separately) must be installed be

tween the furnace and the floor. See table 2 for open

ing size to cut in the floor.

TABLE 2

ADDITIVE BASE FLOOR OPENING

Front to Rear Side to Side

UNIT

in mm in mm

G24M-45/60/75 21-7/8 556 17-5/16 440

G24M-100/120 21-7/8 556 20-3/4 528

G24M-140 21-7/8 556 23-1/2 597

NOTE - Floor opening dimensions listed are 1/4" (6mm) larger than addi

tive base openings.

G24M UNIT

SUPPLY AIR

PLENUM

ADDITIVE

BASE

PROPERLY

SIZED FLOOR

OPENING

1. Cut correct size floor opening

2. Set additive base into opening.

3. Set supply air plenum into additive base.

4. Set unit.

COMBUSTIBLE FLOORING INSTALLATION

FIGURE 8

Loading...

Loading...