Page 23

11. Primary Limit Control (S10)

The primary limit (S10) on G60UH(X) units is located in the

heating vestibule panel. When excess heat is sensed in the

heat exchanger, the limit will open. If the limit is open, the fur-

nace control energizes the supply air blower and closes the

gas valve.The limit automatically resets when unit temperature

returns to normal. The switch must reset within three minutes

or the SureLight board will go into Watch guard for one hour. If

the limit opens during a second stage heat call, the blower

will operate on high heat for 30 seconds and then switch to

low heat speed for the remainder of the 3 minute period. The

switch is factory set (see face of switch) and cannot be ad-

justed. Replace switch with exact length and set point.

12. Secondary Limit Controls (S21)

The secondary limit (S21) on G60UH(X) units is located in the

blower compartment on the back side of the blower housing.

See figure 6. Blower speed chart on the wiring diagram show

secondary limit quantities per unit. When excess heat is

sensed in the blower compartment, the limit will open. If the

limit is open, the furnace control energizes the supply air blow-

er and closes the gas valve. The limit automatically resets

when unit temperature returns to normal. G60UH−1 through −4

units use surface type limts factory set to open at 125°F.

G60UH−5 units and later use air stream type limts factory set

to open at 135°. The secondary limit cannot be adjusted.

13. Gas Valve

The G60UH(X) uses a two−stage gas valve manufactured

by Honeywell (figure 14). The valve is internally redundant

to assure safety shut−off. If the gas valve must be replaced,

the same type valve must be used.

24VAC terminals and gas control knob or switch are located

on the valve. All terminals on the gas valve are connected to

wires from the electronic ignition control. 24V applied to the ter-

minals energizes the valve.

Inlet and outlet pressure taps are located on the valve. A regu-

lator adjustment screw is located on the valve.

LPG change over kit s are available from Lennox. Kits include

burner orifices and a gas valve regulator conversion kit.

14. Combustion Air Inducer

Prove Switch (S18)

G60UH(X) series units are equipped with a dual combustion

air proving switch (first and second stage) located on the

combustion air inducer orifice bracket. The switch is con-

nected to the combustion air inducer housing by means of a

flexible silicone hose. It monitors negative air pressure in the

combustion air inducer housing.

The switches are a single-pole single-throw proving switch

electrically connected to the furnace control. The purpose of

the switch is to prevent burner operation if the combustion

air inducer is not operating or if the flue becomes obstructed.

On heat demand (first or second stage) the switch senses

that the combustion air inducer is operating. It closes a cir-

cuit to the furnace control when pressure inside the com-

bustion air inducer decreases to a certain set point.

Set points vary depending on unit size. See tables 12, 13

and 14. The pressure sensed by the switch is negative rela-

tive to atmospheric pressure. If the flue becomes ob-

structed during operation, the switch senses a loss of neg-

ative pressure (pressure becomes more equal with atmo-

spheric pressure) and opens the circuit to the furnace con-

trol and gas valve. A bleed port on the switch allows rela-

tively dry air in the vestibule to purge switch tubing, to pre-

vent condensate build up.

The switch is factory set and is not field adjustable. It is a

safety shut-down control in the furnace and must not be by−

passed for any reason. If switch is closed or by−passed, the

control will not initiate ignition at start up.

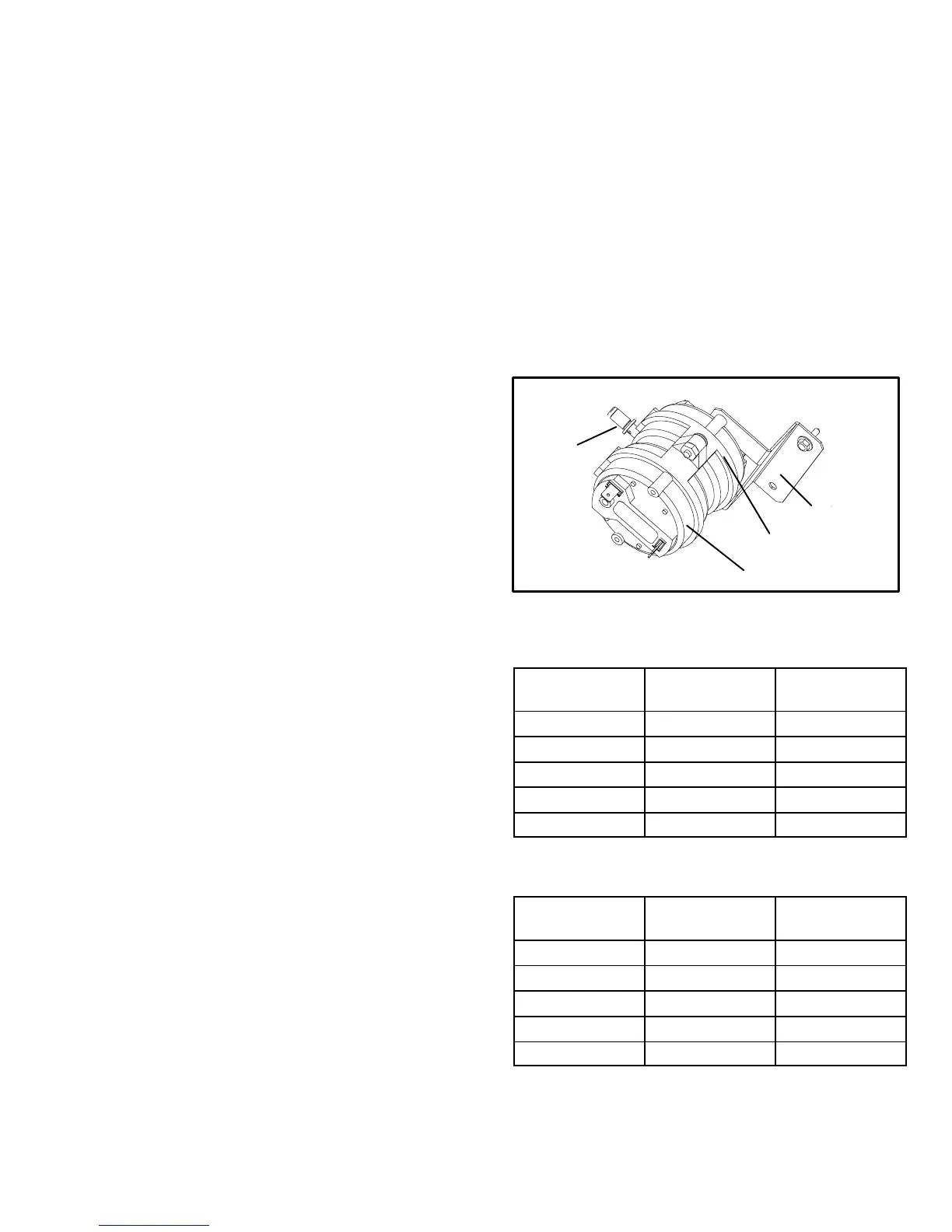

FIGURE 13

DUAL COMBUSTION AIR PROVE SWITCH

BRACKET

TAP

LOW FIRE SWITCH

HIGH FIRE SWITCH

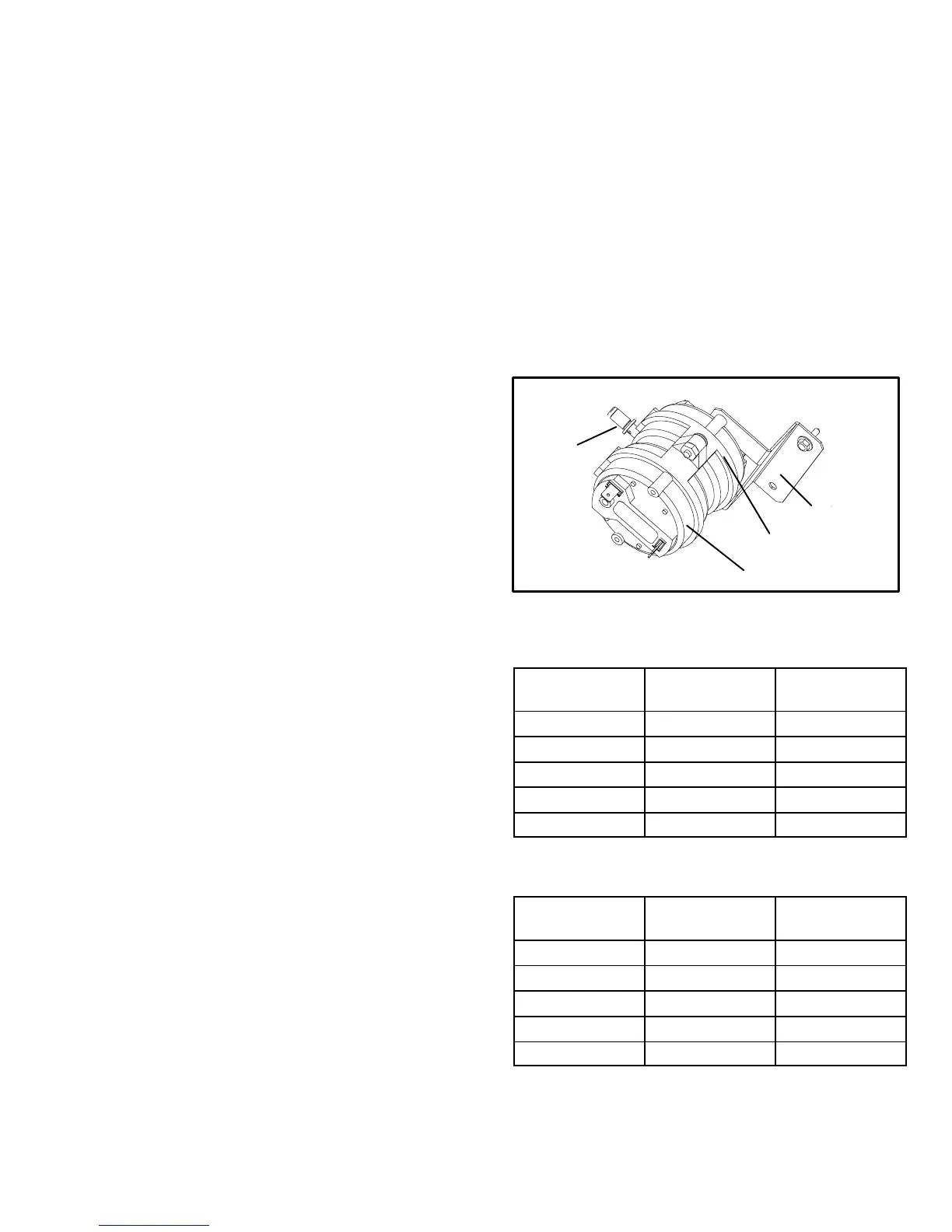

TABLE 12

0’ to 4500’

G60UH(X) Unit

Set Point High

Heat

Set Point Low

Heat

−045 0.40" 0.20"

−070 0.40" 0.20"

−090 0.45" 0.20"

−110 0.50" 0.20"

−135 0.50" 0.20"

TABLE 13*

4501’ to 7500’

G60UH(X) Unit

Set Point High

Heat

Set Point Low

Heat

−045 0.40" 0.20"

−070 0.40" 0.20"

−090 0.40" 0.20"

−110 0.45" 0.20"

−135 0.45" 0.20"

*Unit requires conversion kit at this altitude. See High Altitude table.

Loading...

Loading...