Page 22

9. Combustion Air Inducer (B6)

All G60UH(X) units use a two−stage combustion air inducer

to move air through the burners and heat exchanger during

heating operation. The blower uses a 120VAC motor. The

motor operates during all heating operation and is con-

trolled by furnace / blower control A92. The inducer also

operates for 15 seconds before burner ignition (pre-purge)

and for 5 seconds after the gas valve closes (post-purge).

The inducer operates on low speed during first−stage heat,

then switches to high speed for second stage heat.

A proving switch connected to the combustion air inducer ori-

fice plate is used to prove inducer operation. The combustion

air inducer orifice will be different for each model. See table 11

for orifice sizes. The switch monitors air pressure in the induc-

er housing. During normal operation, the pressure in the

housing is negative. If pressure becomes less negative (sig-

nifying an obstruction) the proving switch opens. When the

proving switch opens, the furnace control (A92) immediately

closes the gas valve to prevent burner operation.

TABLE 11

G60UH(X) Unit

C.A.I. Orifice Size

−045−1, −2 1.25"

−070−1, −2, −3 1.5"

−070−4 and later 1.438"

−090 all units 1.75"

−110−1, −2, −3 2.0"

−110−4 and later 1.875"

−135−1, −2, −3 2.25"

−135−4 and later 2.156"

Horizontal Applications

The G60UH(X) furnace can be installed in horizontal ap-

plications.

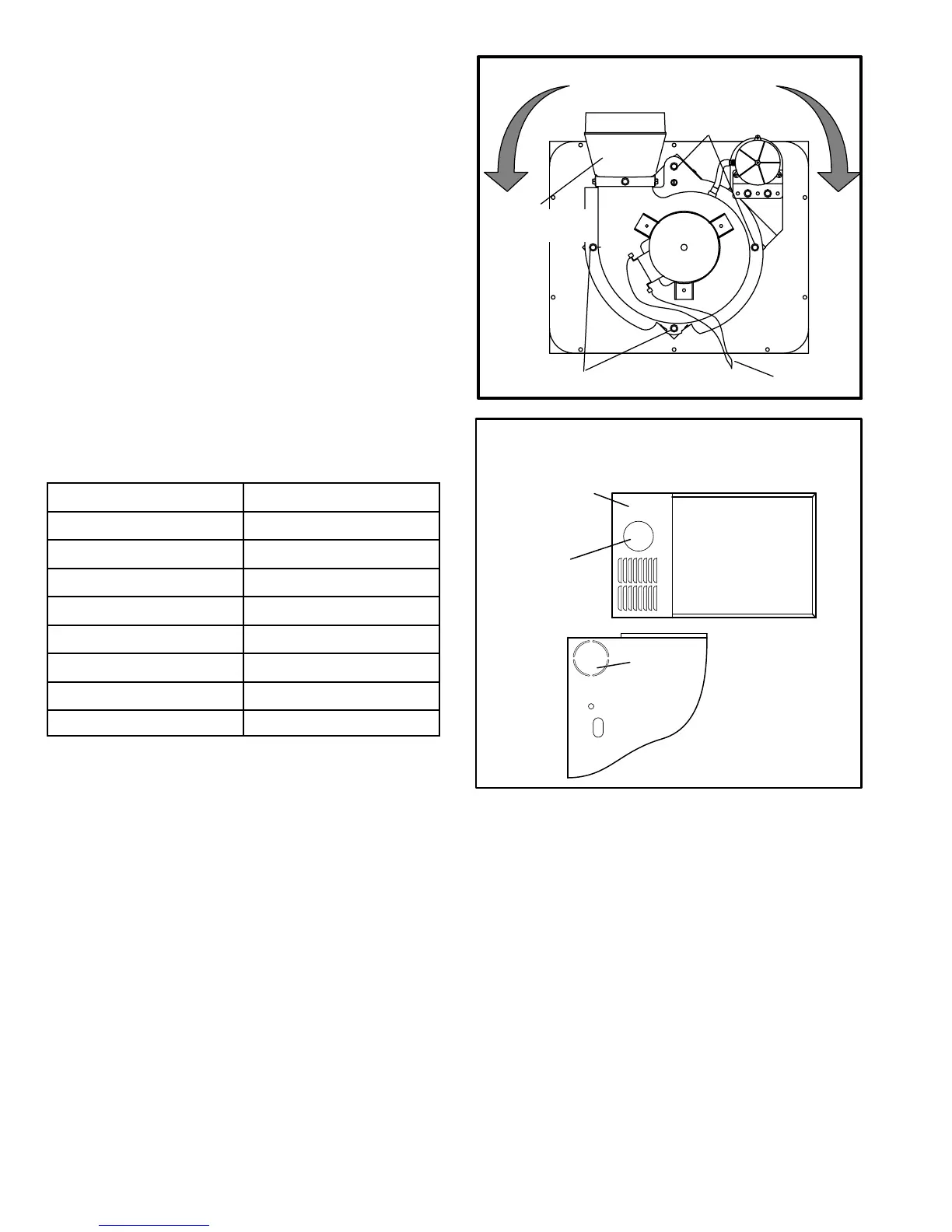

The combustion air inducer may be rotated clockwise or

counterclockwise by 90° to allow for vertical vent discharge

in a horizontal application. Remove the four mounting

screws, rotate the assembly (assembly consists of orifice

plate, proving switch, gasket and combustion air inducer),

then reinstall the mounting screws. See figure 11. Use the

provided wire tie to bundle the pressure switch wires with

the inducer motor power leads. Route the wires away

from moving parts and the heat of the inducer motor to

prevent damage to the wires. Use sheet metal shears to

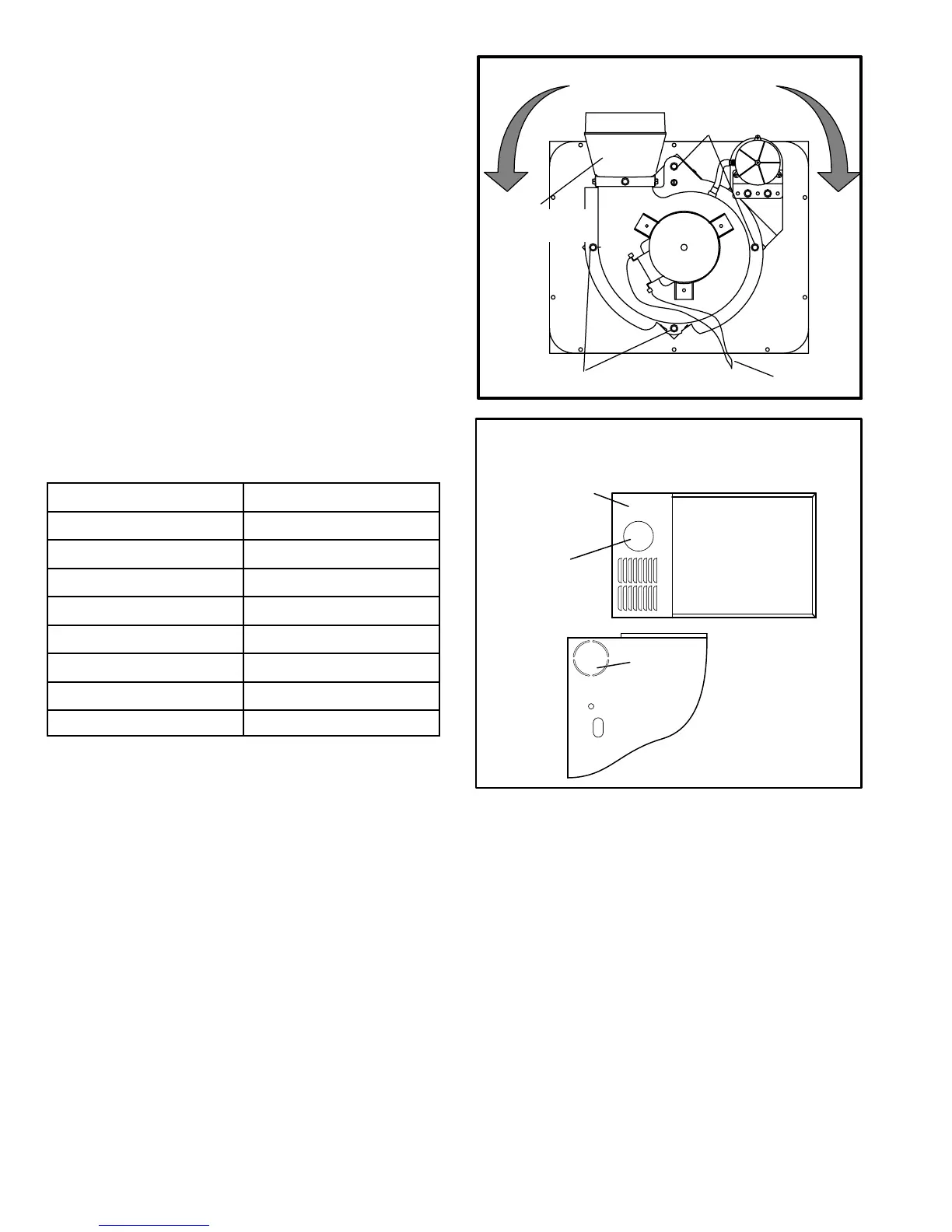

remove the cut out from the side of the cabinet. See figure

12. Use the two provided sheet metal screws to install the

cut out on the top cap to cover the original flue outlet open-

ing.

Combustion Air Inducer

(Upflow Position)

Mounting Screws

MOUNTING SCREWS

90°

90°

(Remove)

(Remove)

Power Leads

Flue Transition

(Do not remove

)

FIGURE 11

Flue Outlet Hole

(

Reattach

Cutout Here)

Supply Air

Opening

Top View of Furnace

Top Cap

Cut out

Optional

Flue Outlet

Optional Flue Outlet

(Horizontal Installation)

FIGURE 12

10. Flame Rollout Switches (S47)

On all G60UH −1, −2 and −3 units, flame rollout switch is a

high temperature limit located on top of the burner box.

Each furnace is equipped with two identical switches. One

switch is located over the leftmost burner and the other

switch is located over the rightmost burner. On G60UH−4

and later model units, the switches are located on a bracket

inside the burner box. The limits are N.C. SPST manual-re-

set limits. When S47 senses rollout, the circuit breaks and

the ignition control immediately stops ignition and closes

the gas valve.

If unit is running and flame rollout is detected, the gas valve

will close and ignition control will be disabled. Rollout can

be caused by a blocked heat exchanger, flue or lack of

combustion air. The switch is factory set to trip (open) at

210°F and cannot be adjusted. The switch can be manually

reset. To manually reset a tripped switch, push the reset but-

ton located on the control.

Loading...

Loading...