Page 19

FIGURE 14

TO PLACE CONTROL IN TEST MODE:

1− Make sure all control terminals are connected as shown

on unit wiring diagram before attempting to place control

in test mode. See NOTE.

2− Turn indoor thermostat to heat mode and adjust to high-

est temperature setting.

NOTE − Control will not go into test mode when discon-

nected from unit. Unit load must be applied to control termi-

nals before the control will go into test mode.

3− With unit operating, momentarily short across TEST"

pins as shown.

4− LED should light and unit should operate in defrost mode

for at least 30 seconds or until normal termination.

5− To leave test mode, momentarily short across TEST"

terminals again.

WARNING − AVOID CONTACT WITH OTHER CONTROL

TERMINALS OR CONTROL COMPONENTS.

8− TEST" Pins

Each board is equipped with a set of test pins for use in

troubleshooting the unit. When momentarily shorted

together, these pins initiate a conventional defrost peri-

od. Because the defrost period was initiated by

momentarily shorting the two TEST" pins, the defrost

period must last a minimum of 30 seconds (see fig-

ure 14).

A defrost initiated by shorting the defrost pins together

can be terminated by shorting the defrost pins again.

Otherwise, defrost will be terminated as in normal op-

eration.

The defrost control continually self-tests its internal cir-

cuits. If an internal failure occurs, test mode will not

function and defrost LED will not light.

IMPORTANT − CONTROL WILL BEGIN TEST MODE

ONLY IF NORMAL LOAD IS APPLIED TO CONTROL

TERMINALS. DO NOT ATTEMPT TO OPERATE OR

TEST CONTROL OUT OF UNIT.

HP21−3 Units

HP21−3 units are equipped with a demand defrost system

which initiates a defrost cycle based on temperature differ-

ential and compressor run time. The control board includes

two permanently attached sensors which monitor coil and

outdoor ambient temperatures. The coil temperature sen-

sor is equipped with a spring clip which allows proper

positioning on the outdoor coil return bend. The ambient

temperature sensor is installed in a sampling tube at the

base of the unit. These sensors must not be detached from

the control board and must be replaced as part of the con-

trol board. Do not attempt to cut or splice the temperature

sensor wires.

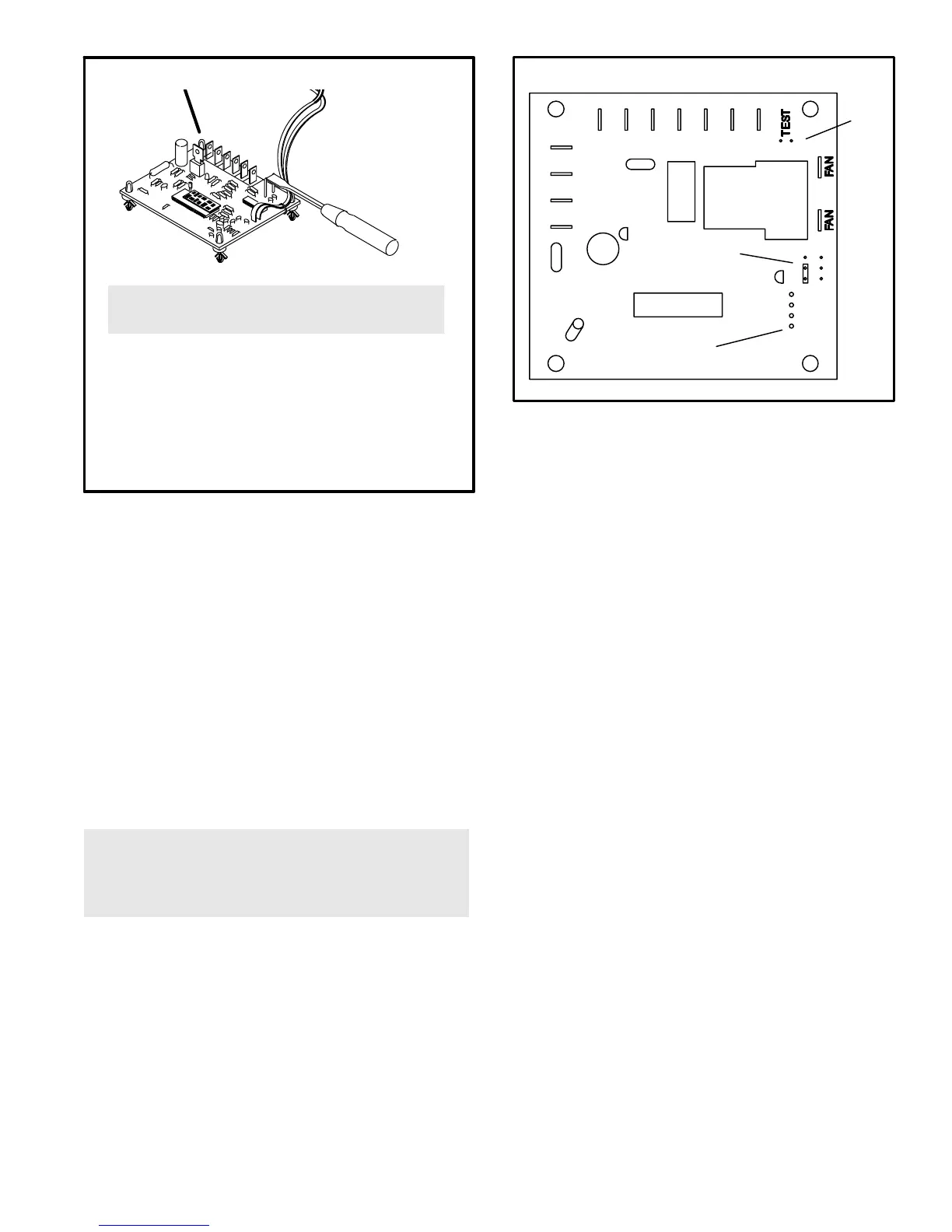

Figure 15

CCWY ORR

Yout

CC

RV

C

AMB

COIL

SENSOR

CONNECTIONS

TEST

PINS

TERMINATION

TEMPERATURE

PINS

HP21−3 DEFROST CONTROL

Operation

When the reversing valve is de−energized, the Y1 circuit is

energized, and the coil temperature is below 35°F (2°C),

the board logs the compressor run time. When the unit is

initially started and the control is not calibrated, a defrost

cycle will be initiated after 34 minutes of heating mode com-

pressor run time. The control will terminate the defrost

cycle when the coil temperature rises above the preset ter-

mination temperature or after 14 minutes of defrost

operation. The termination temperature is factory set at

70°F. This setting may be adjusted in the field to 50°F

(10°C), 60°F (16°C), 70°F (21°C), or 80°F (27°C). The con-

trol will attempt to self−calibrate after this (and all other)

defrost cycle(s). Calibration success depends on stable

system temperatures during the 20−minute calibration peri-

od. If the board fails to calibrate, another defrost cycle will

be initiated after 34 minutes of heating mode compressor

run time. Once the defrost board is calibrated, it will use de-

mand defrost logic to initiate a defrost cycle. A demand

defrost system initiates defrost when the difference be-

tween the clear coil and frosted coil temperatures exceeds

the maximum difference allowed by the control.

If the control determines an ambient temperature sensor

failure and the coil temperature is 35°F (2°C) or lower, the

control will repeatedly initiate a defrost cycle after 34 min-

utes of heating mode compressor run time. If the control

determines that the coil temperature sensor has failed, the

control will not initiate a defrost cycle.

Test Mode

When Y1 is energized and 24V power is being applied to

the board, a test cycle (approximately 12 seconds) can be

initiated by placing the termination temperature jumper

across the Test" pins. If the jumper is applied to the test

pins before power is applied, or if the jumper is left across

the Test" pins longer than 5 minutes, the control will ignore

the test jumper and will revert to normal operation. The test

jumper will initiate continuous defrost cycles until the test

jumper is removed or the 5−minute test period ends.

Loading...

Loading...