Page 50

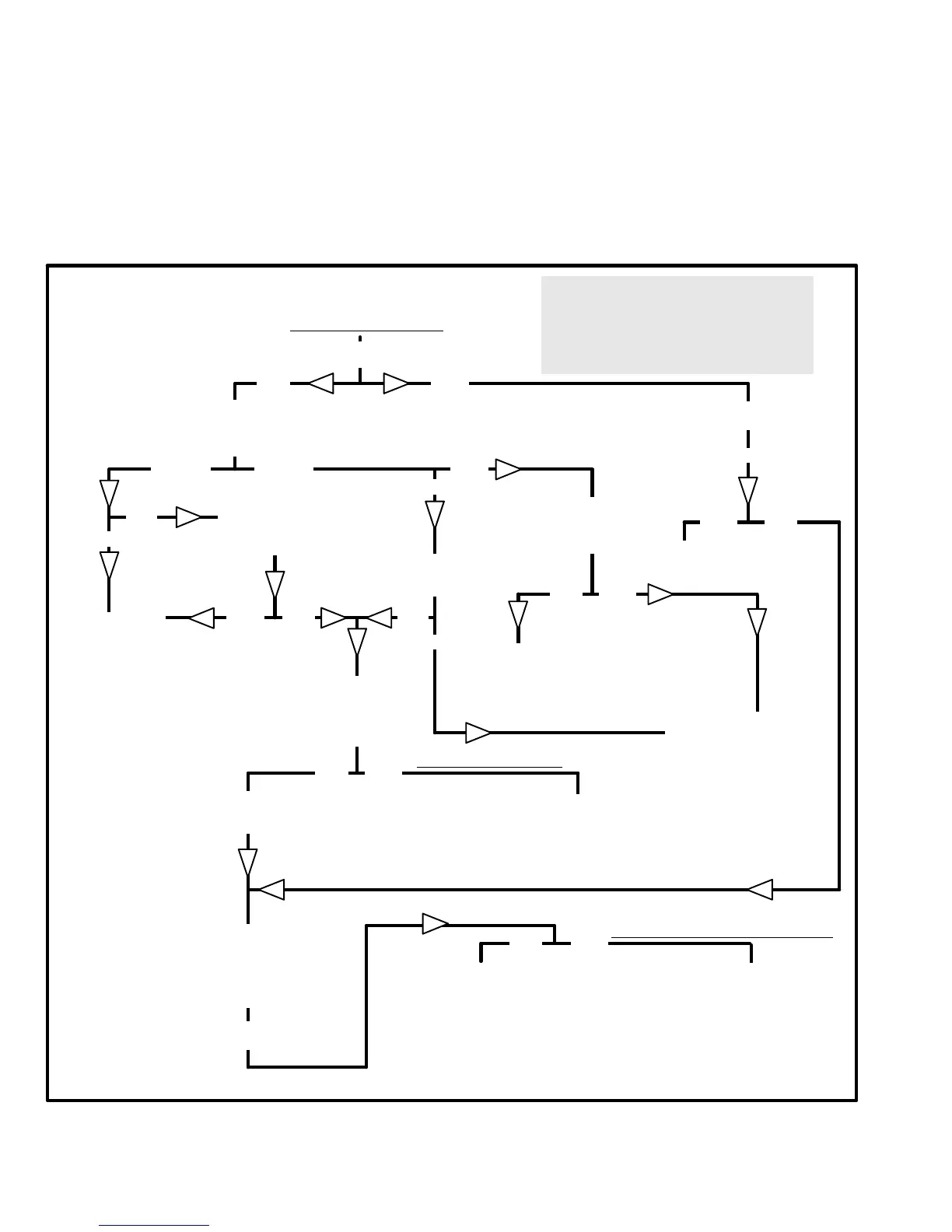

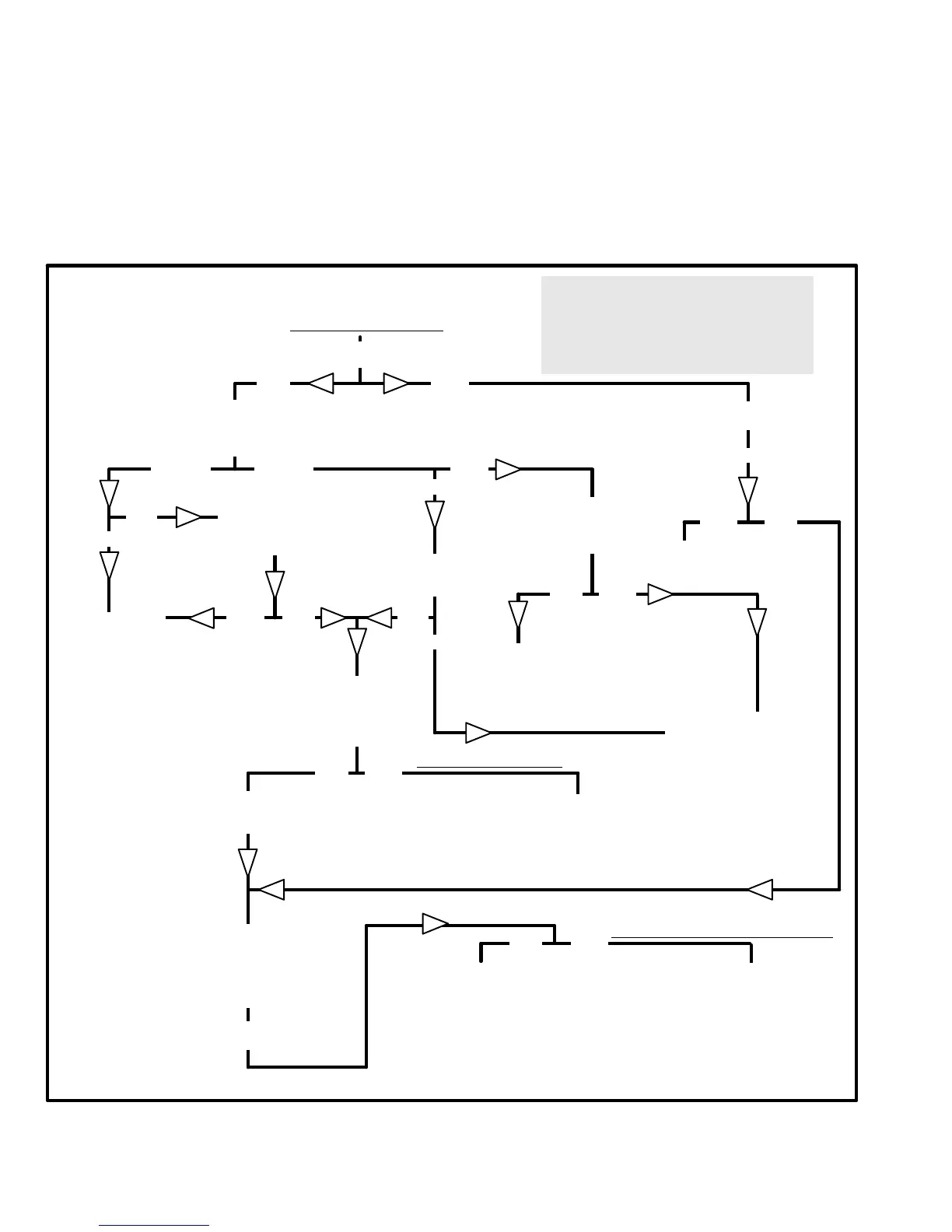

VIII−TROUBLESHOOTING FLOWCHARTS

The following flowcharts show how to diagnose problems

in two-speed heat pumps equipped with TSC control.

Table 19 shows how to determine if the TSC is functioning.

Tables 20a and 20b show how to correlate TSC diagnostics

to the unit.

Follow the flowcharts step by step. Disconnect as few

wires as possible. Any time a repair is made, reassemble

the unit and retest for operation. If the unit does not oper-

ate, recheck up to that point and then continue through the

chart. Occasionally more than one specific problem may

exist. Do as little disassembly as possible and double

check your diagnosis before replacing components.

Be sure to remove all jumper wires and replace all wire con-

nections and access panels before placing unit back in

service.

UNIT WILL NOT RUN

NORMAL LOCKOUT

SAFETY DORMANT LOCKOUT

CHECK VOLTAGE ACROSS COMPRES-

SOR CONTACTOR COILS. IS THERE 24

VAC ACROSS HIGH-SPEED CONTACTOR

COIL?

CONTROL MAY BE LOCKED OUT. TURN

POWER OFF AT DISCONNECT FOR 3 SEC.

IS DIAGNOSTIC LED STILL LIT?

NO YES

TWO-SPEED CONTROL

TROUBLESHOOTING FLOWCHART

TABLE 19

IS DIAGNOSTIC LED

LIT?

SINGLE-

PHASE

THREE-

PHASE

YES

YES

NOYESHIGH−SPEED OR

LOW-SPEED

CONTACTOR IS

FAULTY.

IS THERE 24 VAC

ACROSS LOW-

SPEED CONTACTOR

COIL?

IS THERE 24 VAC

ACROSS LOW-SPEED

CONTACTOR COIL?

NO

IS THERE 24 VAC

ACROSS LOW-

SPEED CONTACTOR

COIL?

CONTROL MAY BE

LOCKED OUT. BREAK

AND REMAKE THERMO-

STAT DEMAND. DOES

COMPRESSOR START?

NO YES

HIGH-SPEED AUXILIARY

SWITCH IS NOT MAKING

PROPERLY. REPLACE

CONTACTOR.

NO

REPLACE

CONTROL

NOYES

YES

HIGH−SPEED OR LOW-

SPEED CONTACTOR

IS FAULTY.

NO

NO YES

CONTROL WAS LOCKED OUT DUE TO UNIT PROB-

LEMS. CONTINUE THROUGH TROUBLESHOOT-

ING FLOWCHART IN THE UNIT INFORMATION

MANUAL TO LOCATE REASON FOR LOCKOUT.

TURN OFF UNIT POWER AT DISCONNECT FOR AT

LEAST 3 SECONDS. TURN POWER ON AND ALLOW

3 SECONDS FOR CONTROL TO POWER-UP.

APPLY THERMOSTAT DEMAND.

CHECK UNIT VOLTAGE AND

MANUALLY RESET CONTROLS.

TRY TO START COMPRESSOR

BY PRESSING AND RELEASING

MANUAL OVERRIDE BUTTON.

DOES COMPRESSOR

START?

NO YES

CONTROL IS PROBABLY GOOD

AND THE PROBLEM IS LOCATED

ELSEWHERE IN THE UNIT. PRO-

CEED THROUGH TROUBLE-

SHOOTING FLOWCHART IN THE

UNIT INFORMATION MANUAL TO

LOCATE THE PROBLEM. START

BY CHECKING ALL MANUALLY

RESET CONTROLS.

CONTROL IS NOW OUT OF SAFE-

TY DORMANT LOCKOUT AND HAS

RESUMED NORMAL OPERATION.

DO NOT REPLACE CONTROL..

SAFETY DORMANT LOCKOUT

WAS PROBABLY CAUSED BY A

SELF-TEST FAILURE OR LINE

VOLTAGE SPIKE.

NOTE−Before beginning this troubleshooting pro-

cedure make sure that 1) primary side of contactor

is supplied with line voltage 2)indoor and outdoor

transformers are delivering 24vac and 3)line volt-

age is supplied to compressor terminals when

contactors engage.

Loading...

Loading...