Page 19

4- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley clock

wise to increase CFM. Turn counterclockwise to de

crease CFM. See figure 7. Do not exceed minimum and

maximum number of pulley turns as shown in table 1.

TABLE 1

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt

Minimum

Turns Open

Maximum

Turns Open

A Section No minimum 5

B Section 1* 6

*No minimum number of turns open when B belt is used on

pulleys 6” O.D. or larger.

Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are main

tained. Tension new belts after a 24-48 hour period of op

eration. This will allow belt to stretch and seat grooves.

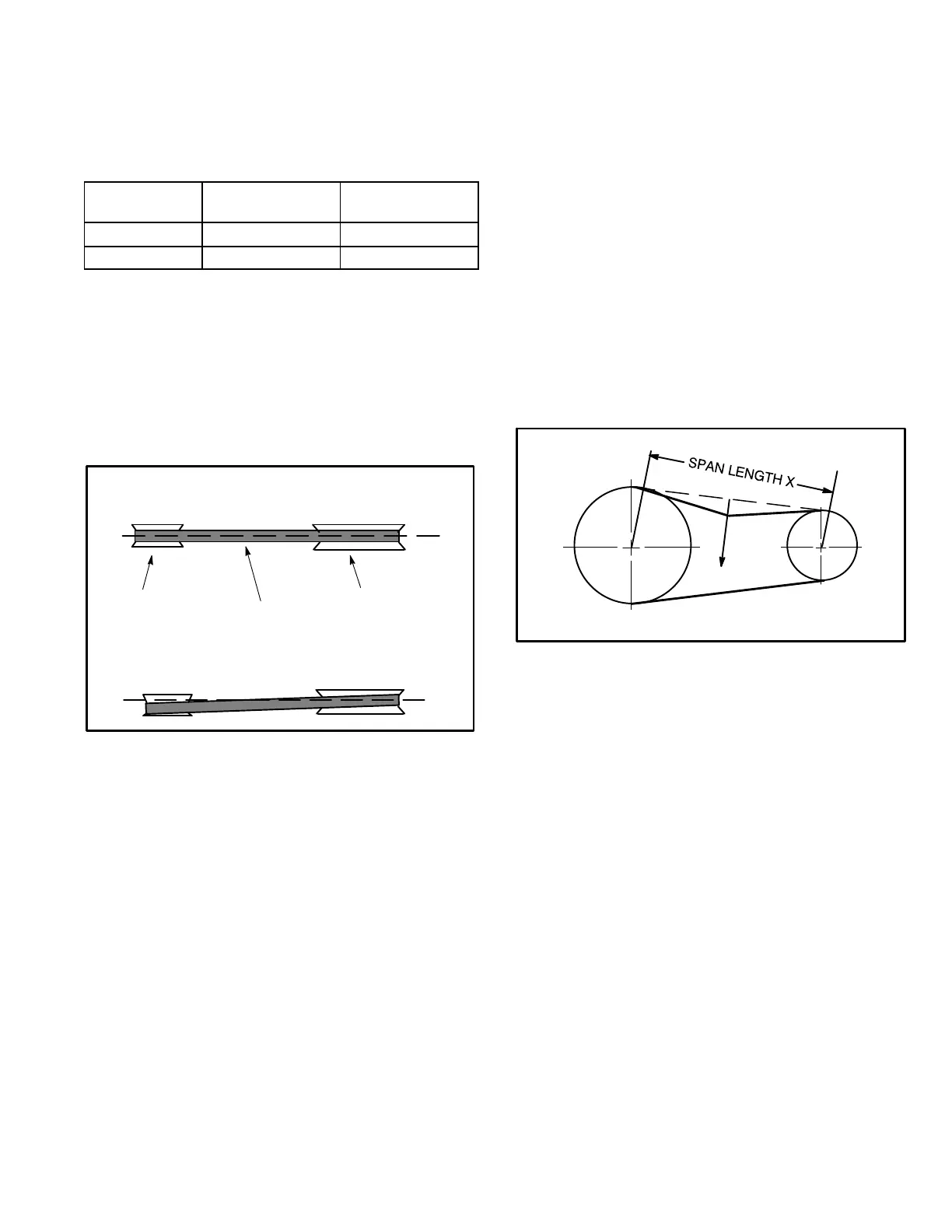

Make sure blower and motor pulley are aligned as shown in

figure 8.

FIGURE 8

PULLEY ALIGNMENT

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

1- Loosen four bolts securing motor base to mounting

frame. See figure 7.

2- To increase belt tension -

Turn adjusting bolt to the right, or clockwise, to move

the motor outward and tighten the belt. This increases

the distance between the blower motor and the blower

housing.

To loosen belt tension -

Turn the adjusting bolt to the left, or counterclockwise

to loosen belt tension.

IMPORTANT - Align top edges of blower motor base and

mounting frame base parallel before tightening two bolts on

the other side of base. Motor shaft and blower shaft must be

parallel.

3- Tighten bolts on side of base.

Check Belt Tension

Overtensioning belts shortens belt and bearing life. Check

belt tension as follows:

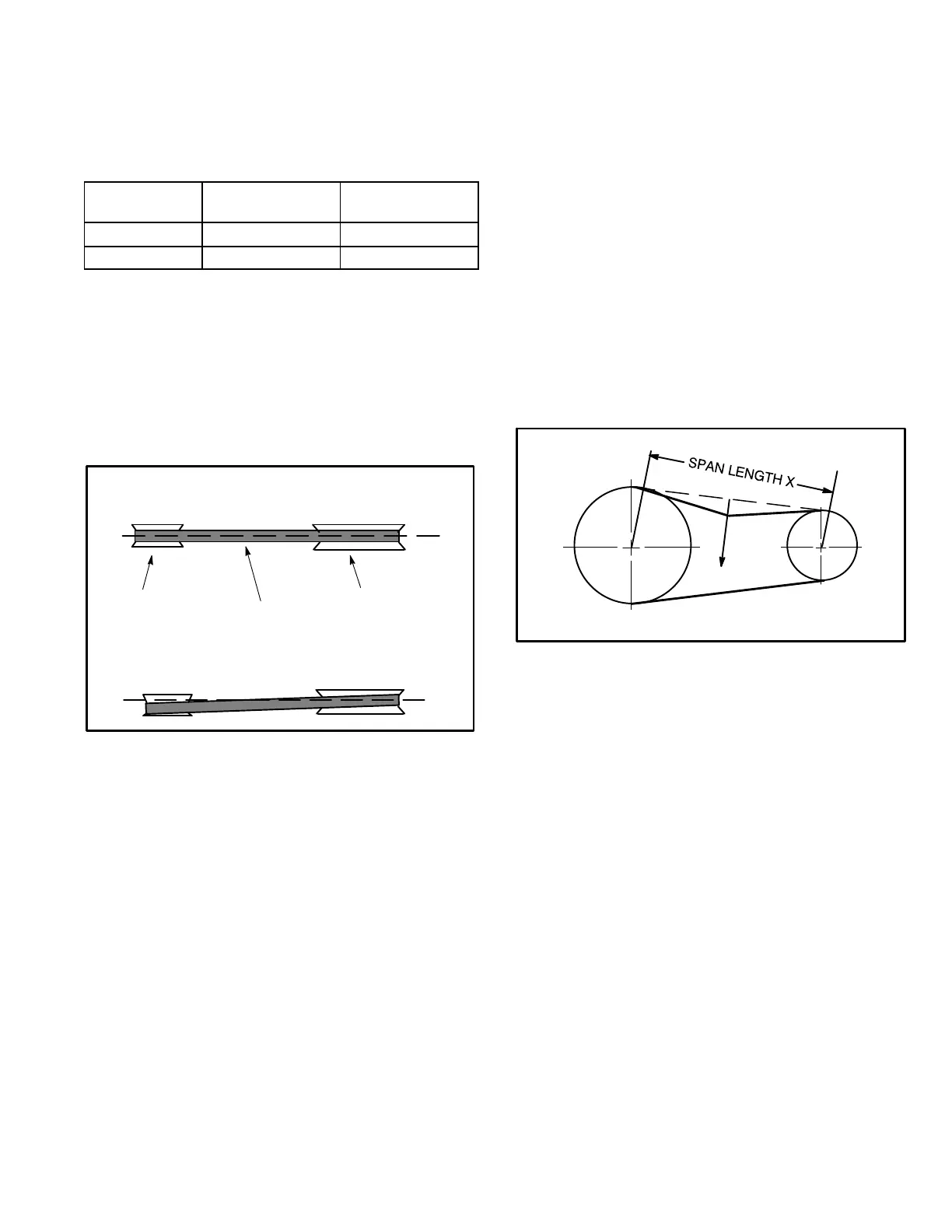

1- Measure span length X. See figure 9.

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch of

span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span would

be 6mm.

3- Measure belt deflection force. For a used belt, the

deflection force should be 5 lbs. (35kPa). A new belt

deflection force should be 7 lbs. (48kPa).

A force below these values indicates an underten

sioned belt. A force above these values indicates an

overtensioned belt.

MEASURE BELT TENSION

FIGURE 9

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FORCE

Loading...

Loading...