Page 41

1 - -

scribed in section D.

2 -

required.

3 - Clean tubes with a wire brush.

4 -

and combustion air inducer gasket should also be

replaced during reassembly.

F-Evaporator Coil

Inspect and clean coil at beginning of each cooling season.

Clean using mild detergent or commercial coil cleaner.

G-Condenser Coil

Clean condenser coil annually with water and inspect

monthly during the cooling season.

Clean the coil by spraying the coil steadily and uniformly

nozzle must be at least 12 inches from the coil face.

prevent damage.

H-Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

access panel or to clean blower wheel.

I-Electrical

1 - Check all wiring for loose connections.

2 -

3 - Check amp-draw on both condenser fan motor and

blower motor.

VII-OPTIONAL ACCESSORIES

The accessories section describes the application of most

of the optional accessories which can be installed to the

KGC units.

A-LP / Propane Kit

the natural to LP gas changeover kit installation instruc-

tions.

when excessive condensate collects in the drain pan.

will be energized.

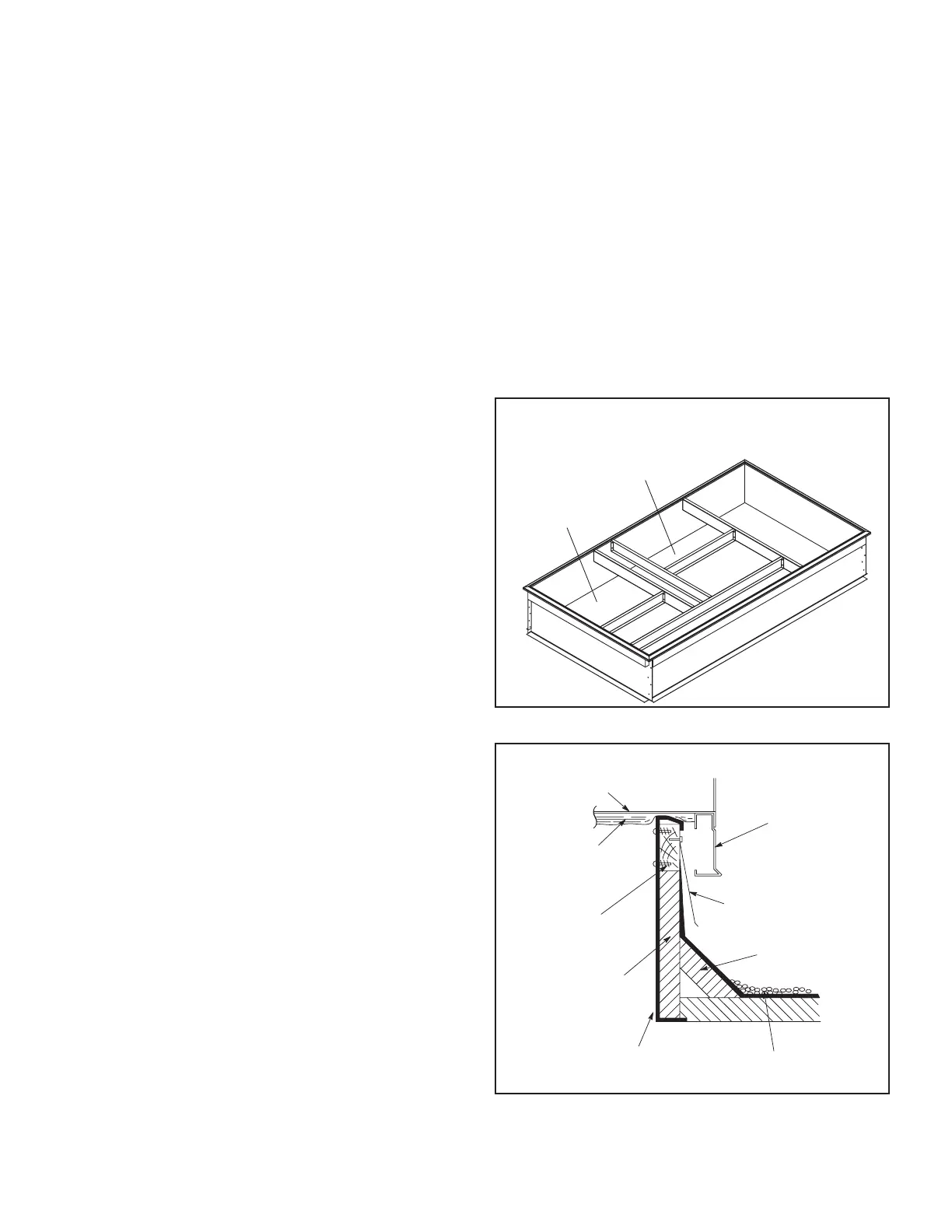

C-C1CURB Mounting Frames

is used. The roof mounting frames are recommended in

all other applications but not required. If the KGA/KGB

be supported under all edges and under the middle of

the unit to prevent sagging. The units MUST be installed

direction.

instructions for details of proper assembly and installation.

The roof mounting frame MUST be squared to the roof

and level before installation. Plenum system MUST be

installed before the unit is set on the mounting frame.

for proper plenum construction and attachment.

ASSEMBLED ROOF MOUNTING FRAME

SUPPLY AIR

OPENING

RETURN AIR

OPENING

FIGURE 28

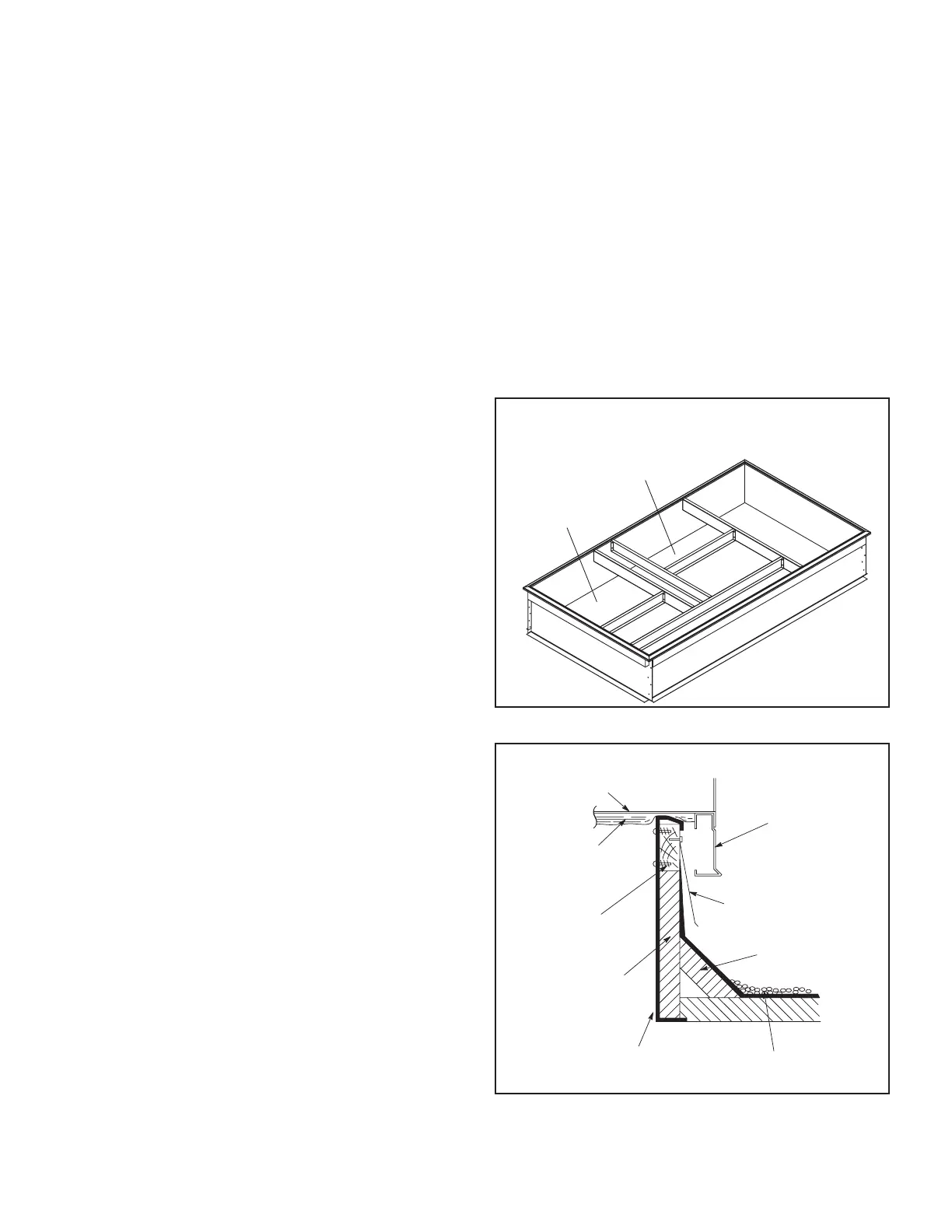

ROOF

MOUNTING FRAME

(Extends around entire

perimeter of unit)

FIBERGLASS

INSULATION

(Furnished)

COUNTER FLASHING

(Field Supplied)

UNIT BASE

BOTTOM

RIGID INSULATION

(Field Supplied)

ROOFING

MATERIAL

CANT STRIP

(Field Supplied)

NAILER STRIP

(Furnished)

UNIT BASE RAIL

FIGURE 29

Loading...

Loading...