Page 39

VI-MAINTENANCE

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect

switch(es). Unit may have multiple power

supplies.

CAUTION

As with any mechanical equipment, contact with

sharp sheet metal edges can result in personal

injury. Take care while handling this equipment and

wear gloves and protective clothing.

A-Filters

should be checked and replaced when necessary with

NOTE - Filters must be U.L.C. certied or equivalent for

use in Canada.

PULL TO

REMOVE

FILTERS

FIGURE 23

B-Lubrication

All motors are lubricated at the factory. No further

lubrication is required.

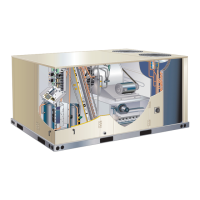

C-Burners (Gas Units)

during the heating season. Before each heating season

examine the burners for any deposits or blockage which

may have occurred.

Clean burners as follows:

1 -

2 -

3 -

and lift the individual burners or the entire burner

as necessary.

4 - Locate the ignitor under the left burners. Check

ignitor spark gap with appropriately sized twist drills

Check the alignment of the ignitor and the sensor

6 - -

place access panel.

7 -

lighting instructions attached to unit and use inspec-

BURNER BOX ASSEMBLY

GAS MANIFOLD

FLAME

SENSOR

GAS

VALVE

(GV1), GV3)

BURNERS

FLAME

ROLLOUT

LIMIT

(S47), (S69)

SPARK

ELECTRODE

FIGURE 24

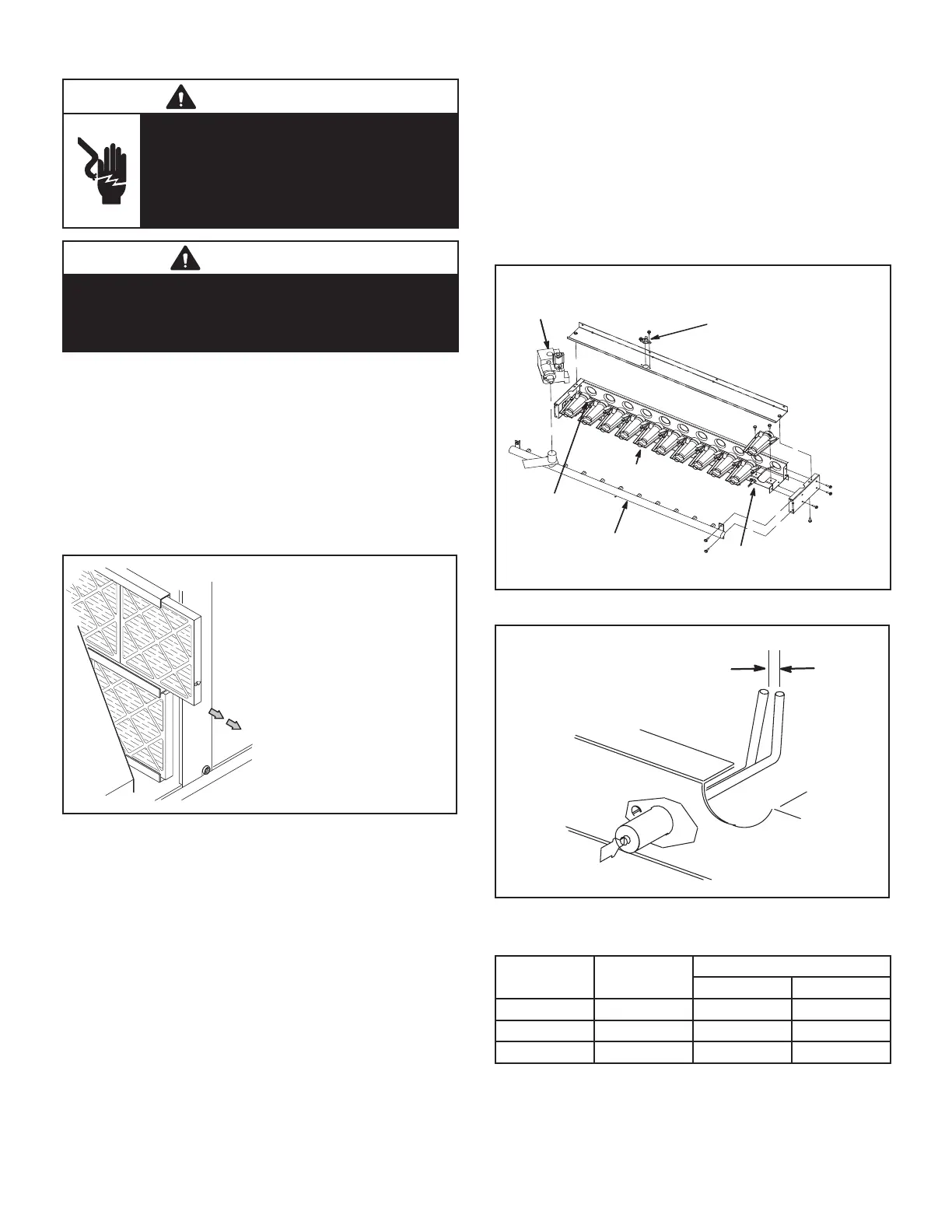

SPARK GAP

SHOULD BE 1/8”

(3mm)

FIGURE 25

TABLE 20

Dimension

Unit

Btuh Input

Length - in. (mm)

Ignitor Sensor

A 130K

B 180K

C 240K

Loading...

Loading...