Page 9

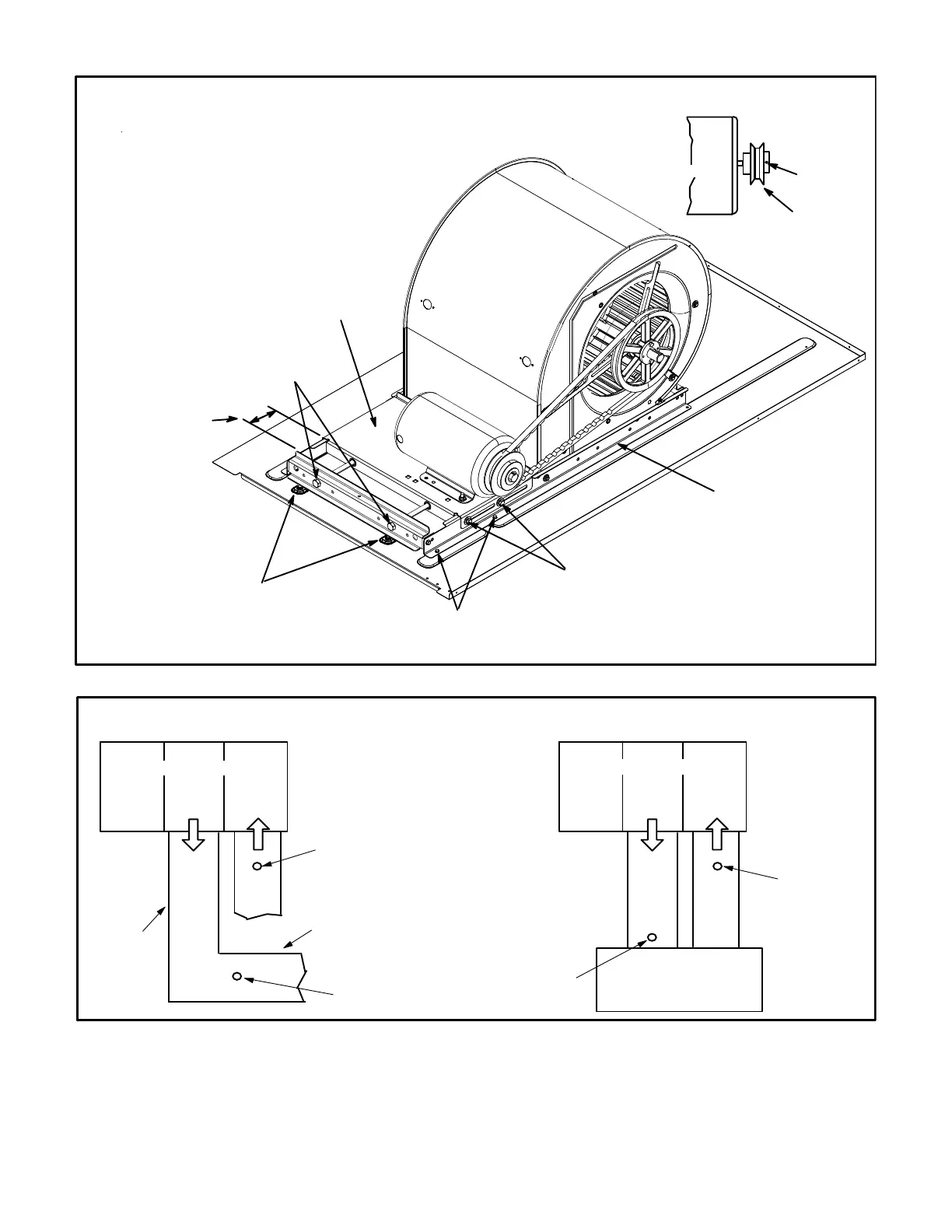

STANDARD BLOWER ASSEMBLY

FIGURE 10

PULLEY

MOTOR

SIDE VIEW

ALLEN

SCREW

BELT ADJUSTING BOLTS

- TURN CLOCKWISE

TO TIGHTEN BELT

MOTOR MOUNTING

BASE

LOOSEN BEFORE

ADJUSTING BELT TENSION

(TWO EACH SIDE)

REMOVE TWO SCREWS ON EACH

SIDE TO SLIDE FRAME PARTIALLY

OUT OF UNIT FOR SERVICE ACCESS

MOTOR

BLOWER

HOUSING

BLOWER

FRAME

GAP BETWEEN

EDGES SHOULD BE

PARALLEL ON BOTH

ENDS BEFORE

TIGHTENING MOTOR

MOUNTING BASE IN

PLACE

REMOVE TWO SCREWS

TO COMPLETELY SLIDE

BLOWER OUT OF UNIT

TO INCREASE BELT TENSION

1- Loosen four bolts securing motor mounting base

to frame.

2- Turn adjusting bolt to the right, or clockwise, to

move the motor away from the blower housing.

IMPORTANT - Gap between end of frame and motor

mounting base should be equal at both ends, i.e. par

allel along gap.

3- Tighten four bolts securing motor mounting base

to frame.

4- Relieve tension on two adjusting bolts.

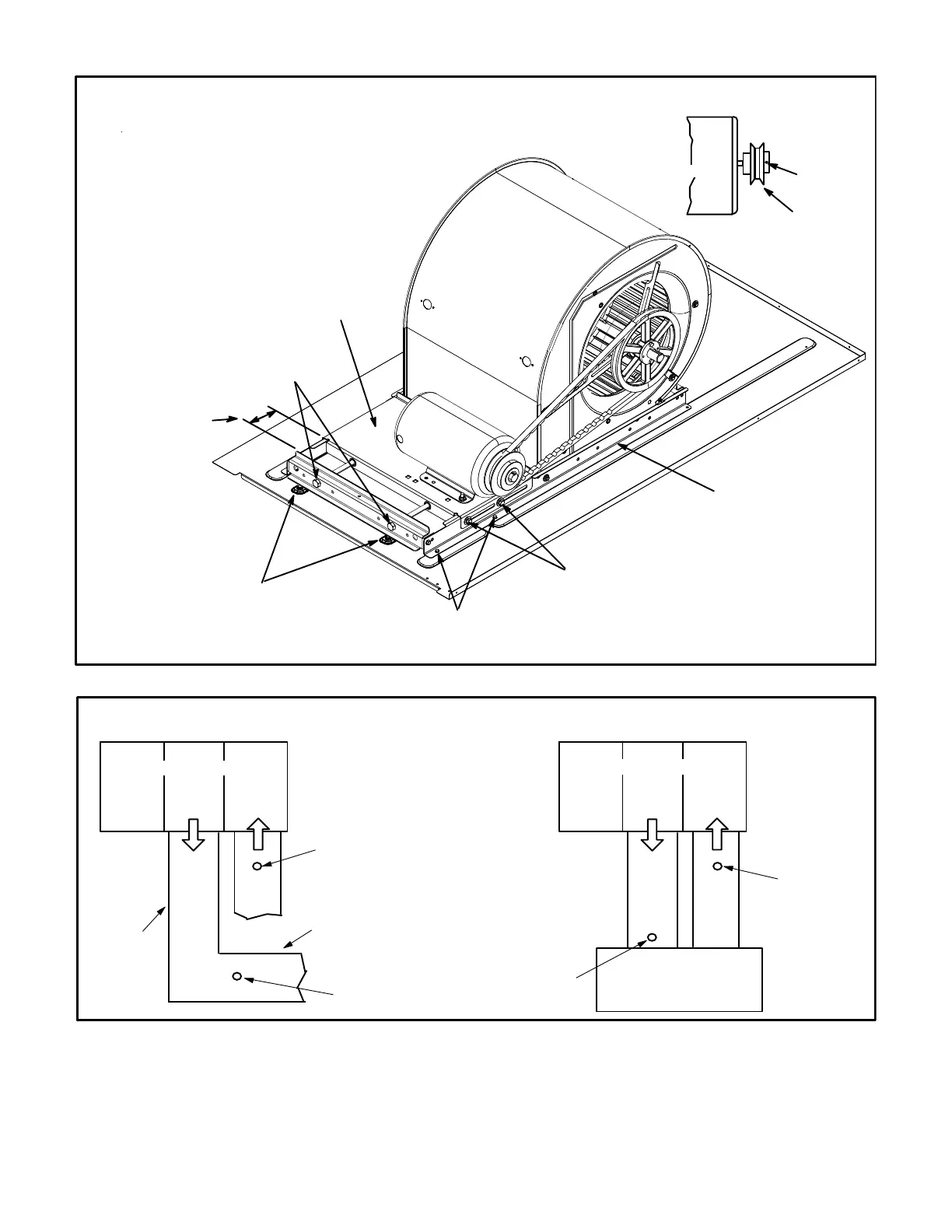

FIGURE 11

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

RE

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

RE

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

Loading...

Loading...