Page 10

Belt Drive Blowers

1- Loosen the reusable wire tie which secures the

blower wiring to the blower motor mounting plate.

2- Remove and retain screws on either side of sliding

frame. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws on either side of the

sliding frame.

D-Determining Unit CFM

IMPORTANT - Belt-driven supply air inverter units are

factory-set to run the blower at full speed when there is a

blower (G) demand without a heating or cooling demand.

Use the following procedure to adjust motor pulley to

deliver the full load cooling or heating CFM. See

Belt-Driven Supply Air Inverter Start-Up section to set

blower CFM for all modes once the motor pulley is set.

1- The following measurements must be made with a

dry indoor coil. Run blower without a cooling demand.

Measure the indoor blower shaft RPM. Air filters must

be in place when measurements are taken.

2- With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

readings taken in locations shown in figure 11.

Note - Static pressure readings can vary if not taken

where shown.

3- Referring to page 14, 15, or 16, use static pressure

and RPM readings to determine unit CFM. Use page

17 when installing units with any of the optional

accessories listed.

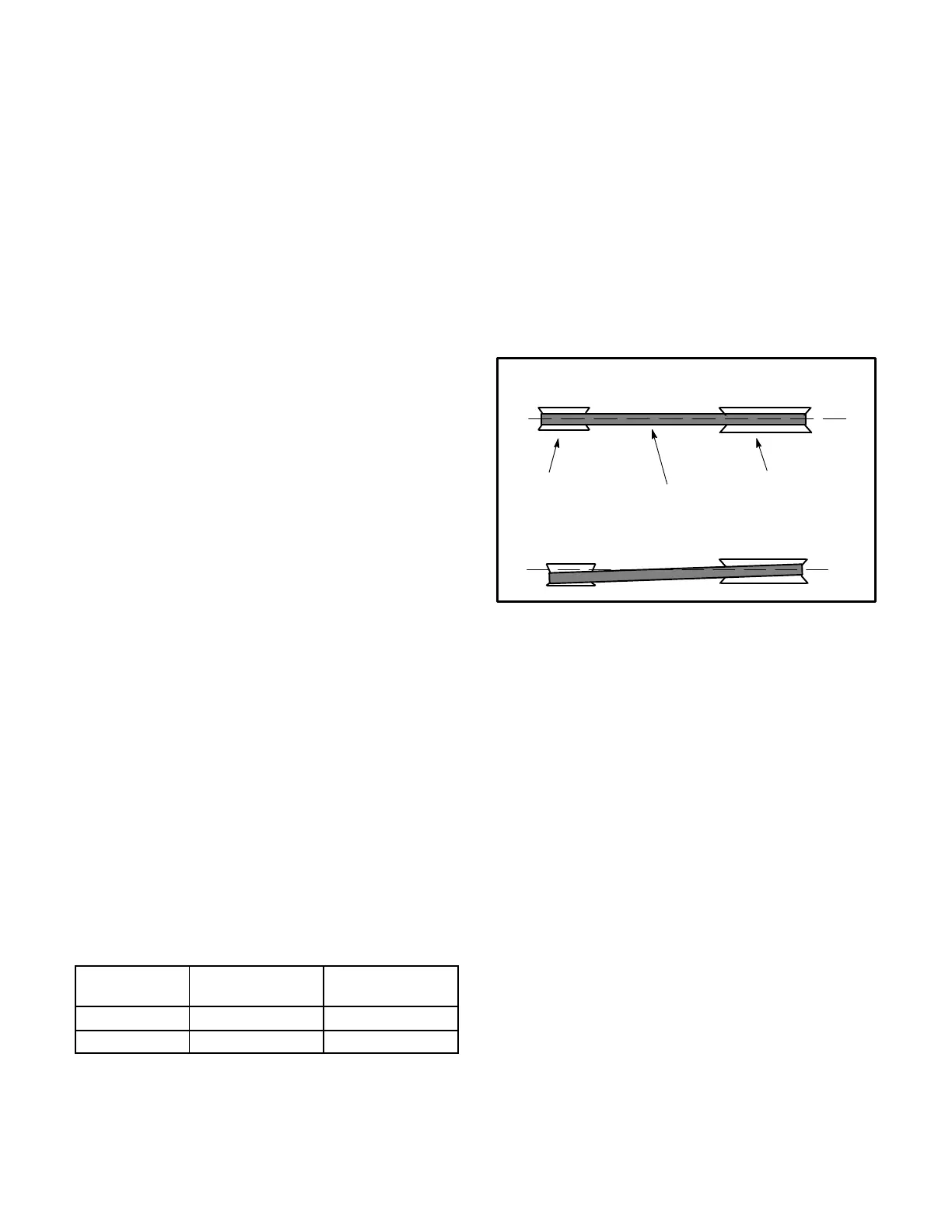

4- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase CFM. Turn counterclockwise to

decrease CFM. See figure 10. Do not exceed

minimum and maximum number of pulley turns as

shown in table 2.

TABLE 2

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt

Minimum

Turns Open

Maximum

Turns Open

A Section 0 5

B Section 1* 6

*No minimum number of turns open when B belt is used on

pulleys 6” O.D. or larger.

E-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only

if proper pulley alignment and belt tension are

maintained. Tension new belts after a 24-48 hour

period of operation. This will allow belt to stretch and

seat in the pulley grooves. Make sure blower and motor

pulleys are aligned as shown in figure 12.

1- Loosen four bolts securing motor base to mounting

frame. See figure 10.

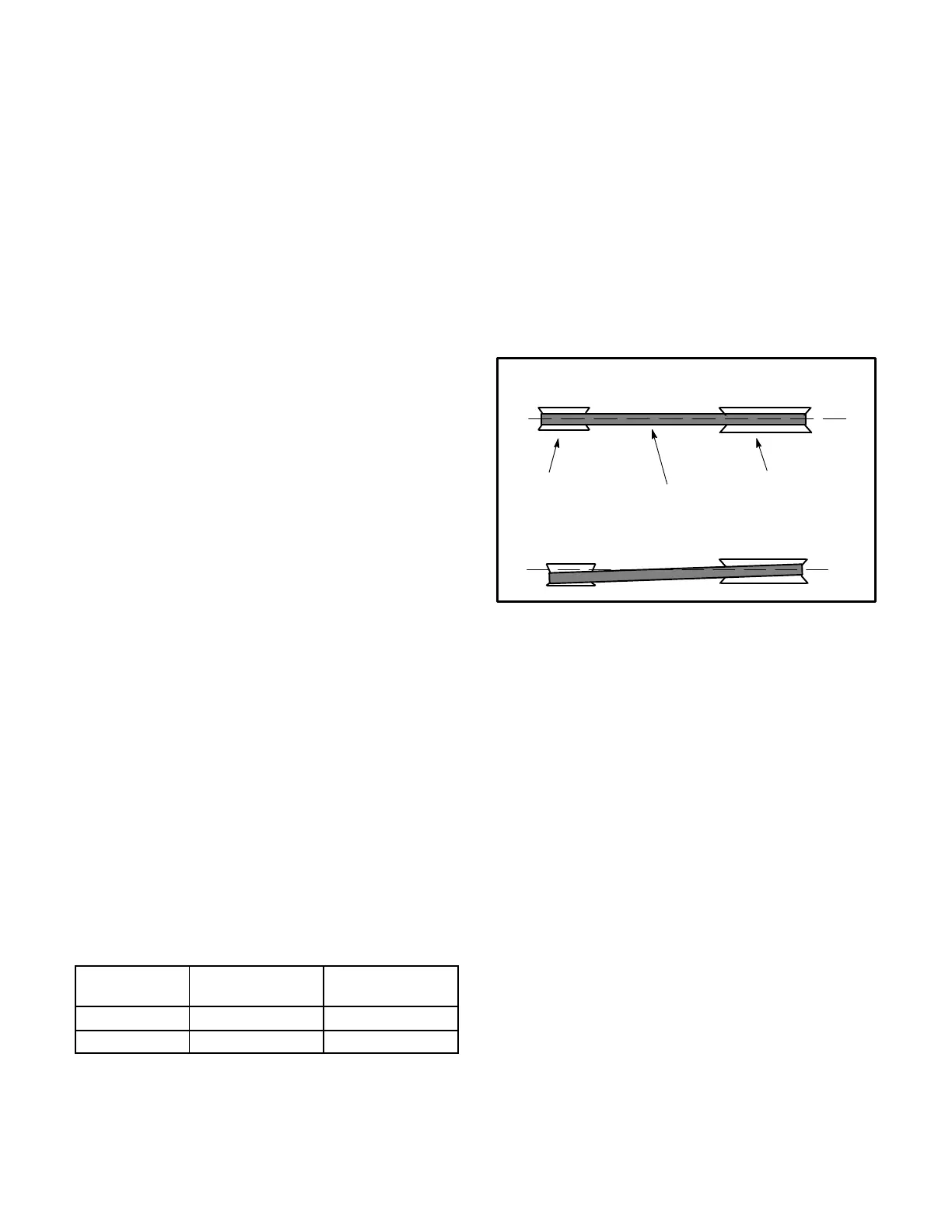

FIGURE 12

PULLEY ALIGNMENT

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

2- To increase belt tension -

Turn both adjusting bolts to the right, or clockwise, to

move the motor outward and tighten the belt. This

increases the distance between the blower motor and

the blower housing.

To loosen belt tension -

Turn the adjusting bolts to the left, or

counterclockwise to loosen belt tension.

IMPORTANT - Align top edges of blower motor base and

mounting frame base parallel before tightening four bolts

on the side of base. Motor shaft and blower shaft must be

parallel.

3- Tighten two bolts on each side of the motor mounting

base. This secures the mounting base to the frame.

4- Relieve tension adjusting bolts.

Loading...

Loading...