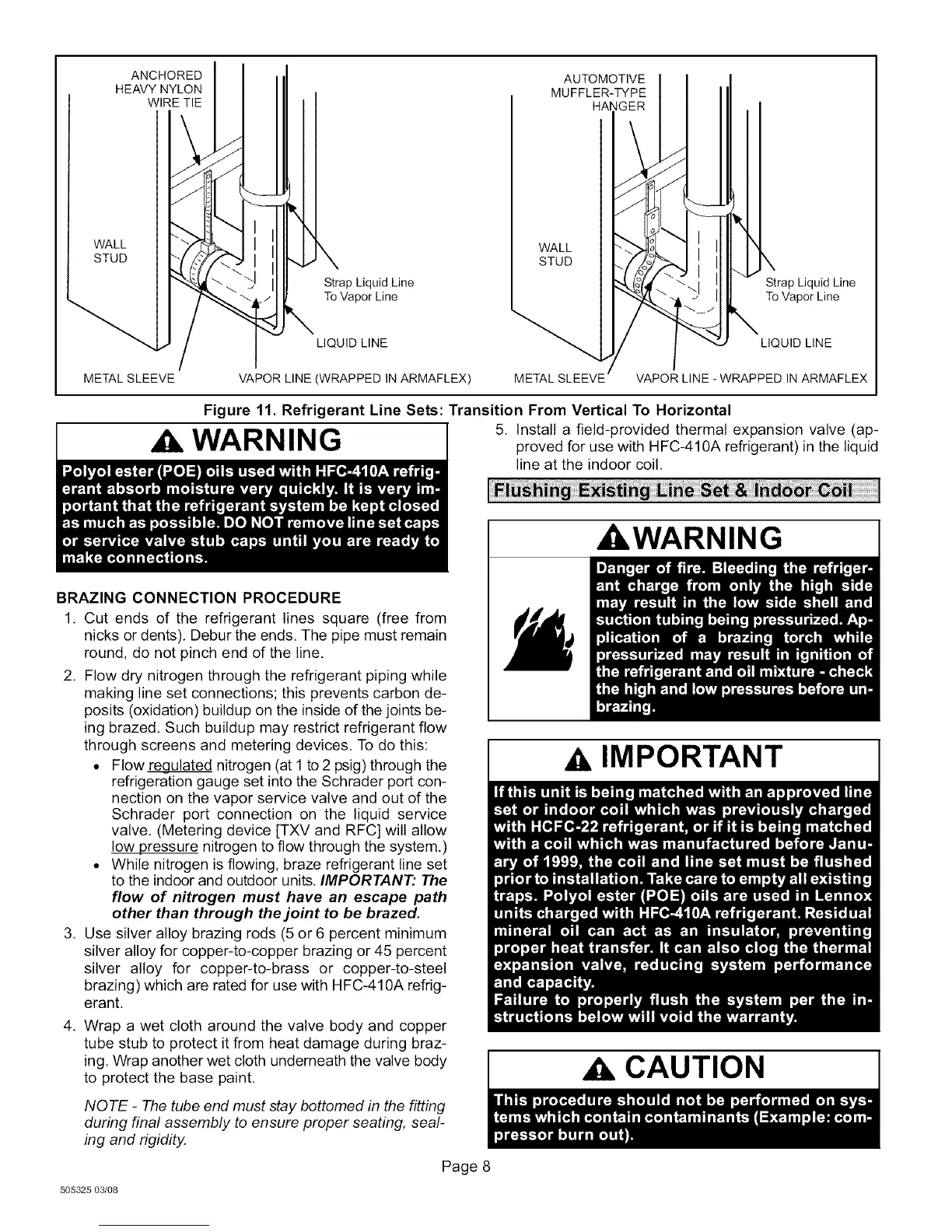

ANCHORED

HEAVY NYLON

WIRE TIE

AUTOMOTIVE

MUFFLER-TYPE

HANGER

WALL

STUD

WALL

STUD

Strap Liquid Line

To Vapor Line

LIQUID LINE

Strap Liquid Line

To Vapor Line

LIQUID LINE

METAL SLEEVE

VAPOR LINE (WRAPPED IN ARMAFLEX)

VAPOR LINE -WRAPPED IN ARMAFLEX

Figure 11. Refrigerant Line Sets: Transition From Vertical To Horizontal

WARNING I 5, Install a field-provided thermal expansion valve (ap-proved for use with HFC-410A refrigerant) in the liquid

line at the indoor coil,

BRAZING CONNECTION PROCEDURE

1, Cut ends of the refrigerant lines square (free from

nicks or dents), Debur the ends. The pipe must remain

round, do not pinch end of the line.

2, Flow dry nitrogen through the refrigerant piping while

making line set connections; this prevents carbon de-

posits (oxidation) buildup on the inside of the joints be-

ing brazed. Such buildup may restrict refrigerant flow

through screens and metering devices. To do this:

• Flow_ulated nitrogen (at 1 to 2 psig) through the

refrigeration gauge set into the Schrader port con-

nection on the vapor service valve and out of the

Schrader port connection on the liquid service

valve. (Metering device [TXV and RFC] will allow

low pressure nitrogen to flow through the system.)

• While nitrogen is flowing, braze refrigerant line set

to the indoor and outdoor units, IMPORTANT." The

flow of nitrogen must have an escape path

other than through the joint to be brazed.

3, Use silver alloy brazing rods (5 or 6 percent minimum

silver alloy for copper-to-copper brazing or 45 percent

silver alloy for copper-to-brass or copper-to-steel

brazing) which are rated for use with HFC-410A refrig-

erant,

4. Wrap a wet cloth around the valve body and copper

tube stub to protect it from heat damage during braz-

ing, Wrap another wet cloth underneath the valve body

to protect the base paint,

NOTE - The tube end must stay bottomed in the fitting

during final assembly to ensure proper seating, seal-

ing and rigidity.

Page 8

505325 03/08

_WARNING

IMPORTANT

CAUTION

Loading...

Loading...