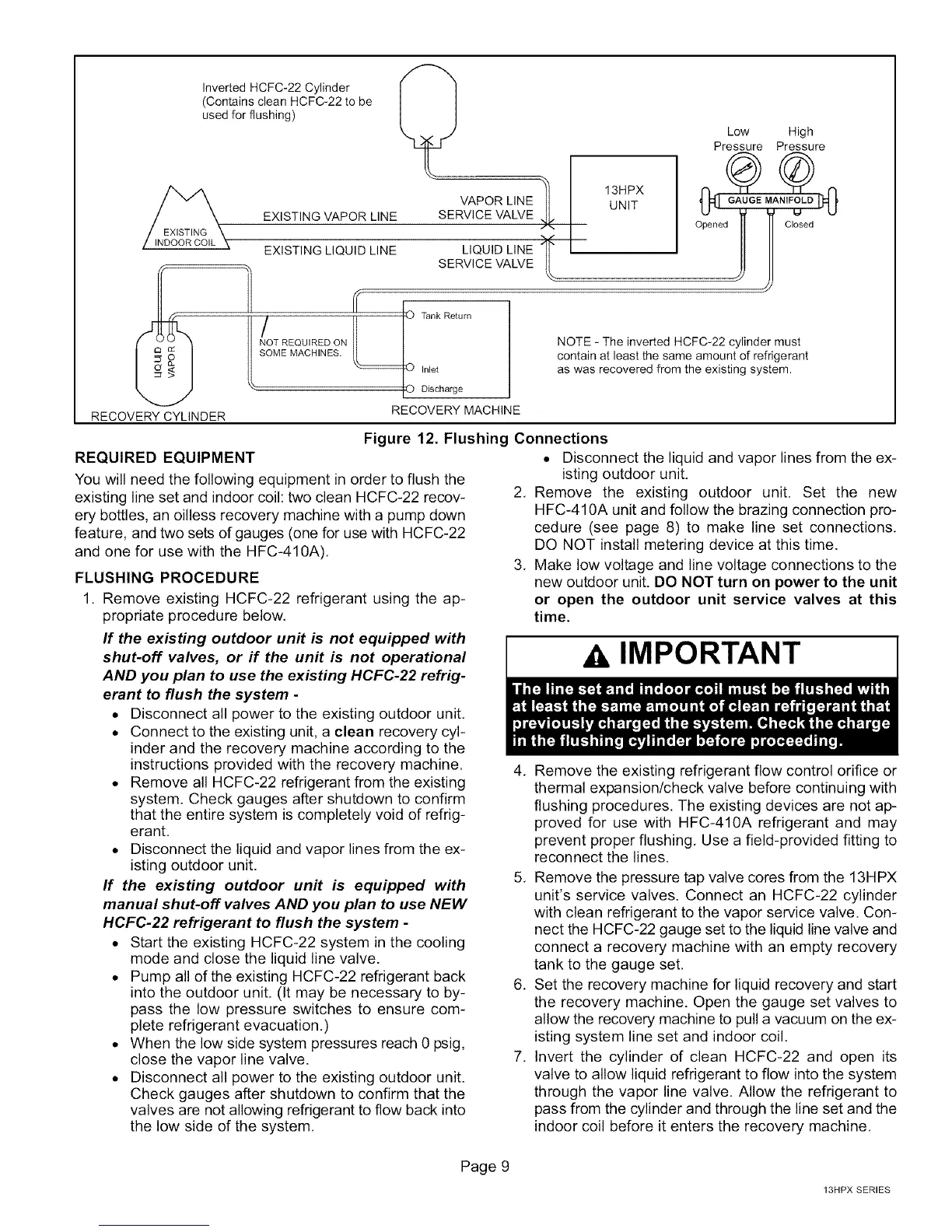

RECOVERY CYLINDER

Inverted HCFC-22 Cylinder

(Contains clean HCFC-22 to be

used for flushing)

EXISTING VAPOR LINE

VAPOR LINE

SERVICE VALVE

EXISTING LIQUID LINE LIQUID LINE

SERVICE VALVE

/ REOU,REDO. ank

SOME MACHINES.

Inlet

r Discharge

RECOVERY MACHINE

Low High

Pressure Pressure

NOTE - The inverted HCFC-22 cylinder must

contain at least the same amount of refrigerant

as was recovered from the existing system.

Figure 12. Flushing Connections

REQUIRED EQUIPMENT

You will need the following equipment in order to flush the

existing line set and indoor coil: two clean HCFC-22 recov-

ery bottles, an oilless recovery machine with a pump down

feature, and two sets of gauges (one for use with HCFC-22

and one for use with the HFC-410A).

FLUSHING PROCEDURE

1. Remove existing HCFC-22 refrigerant using the ap-

propriate procedure below.

If the existing outdoor unit is not equipped with

shut-off valves, or if the unit is not operational

AND you plan to use the existing HCFC-22 refrig-

erant to flush the system -

• Disconnect all power to the existing outdoor unit.

• Connect to the existing unit, a clean recovery cyl-

inder and the recovery machine according to the

instructions provided with the recovery machine.

• Remove all HCFC-22 refrigerant from the existing

system. Check gauges after shutdown to confirm

that the entire system is completely void of refrig-

erant.

• Disconnect the liquid and vapor lines from the ex-

isting outdoor unit.

If the existing outdoor unit is equipped with

manual shut-off valves AND you plan to use NEW

HCFC-22 refrigerant to flush the system -

• Start the existing HCFC-22 system in the cooling

mode and close the liquid line valve.

• Pump all of the existing HCFC-22 refrigerant back

into the outdoor unit. (It may be necessary to by-

pass the low pressure switches to ensure com-

plete refrigerant evacuation.)

• When the low side system pressures reach 0 psig,

close the vapor line valve.

• Disconnect all power to the existing outdoor unit.

Check gauges after shutdown to confirm that the

valves are not allowing refrigerant to flow back into

the low side of the system.

• Disconnect the liquid and vapor lines from the ex-

isting outdoor unit.

2. Remove the existing outdoor unit. Set the new

HFC-410A unit and follow the brazing connection pro-

cedure (see page 8) to make line set connections.

DO NOT install metering device at this time.

3. Make low voltage and line voltage connections to the

new outdoor unit. DO NOT turn on power to the unit

or open the outdoor unit service valves at this

time.

A IMPORTANT

4. Remove the existing refrigerant flow control orifice or

thermal expansion/check valve before continuing with

flushing procedures. The existing devices are not ap-

proved for use with HFC-410A refrigerant and may

prevent proper flushing, Use a field-provided fitting to

reconnect the lines.

5. Remove the pressure tap valve cores from the 13HPX

unit's service valves. Connect an HCFC-22 cylinder

with clean refrigerant to the vapor service valve. Con-

nect the HCFC-22 gauge set to the liquid line valve and

connect a recovery machine with an empty recovery

tank to the gauge set,

6. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the ex-

isting system line set and indoor coil.

7. Invert the cylinder of clean HCFC-22 and open its

valve to allow liquid refrigerant to flow into the system

through the vapor line valve. Allow the refrigerant to

pass from the cylinder and through the line set and the

indoor coil before it enters the recovery machine.

Page 9

13HPX SERIES

Loading...

Loading...