Page 29

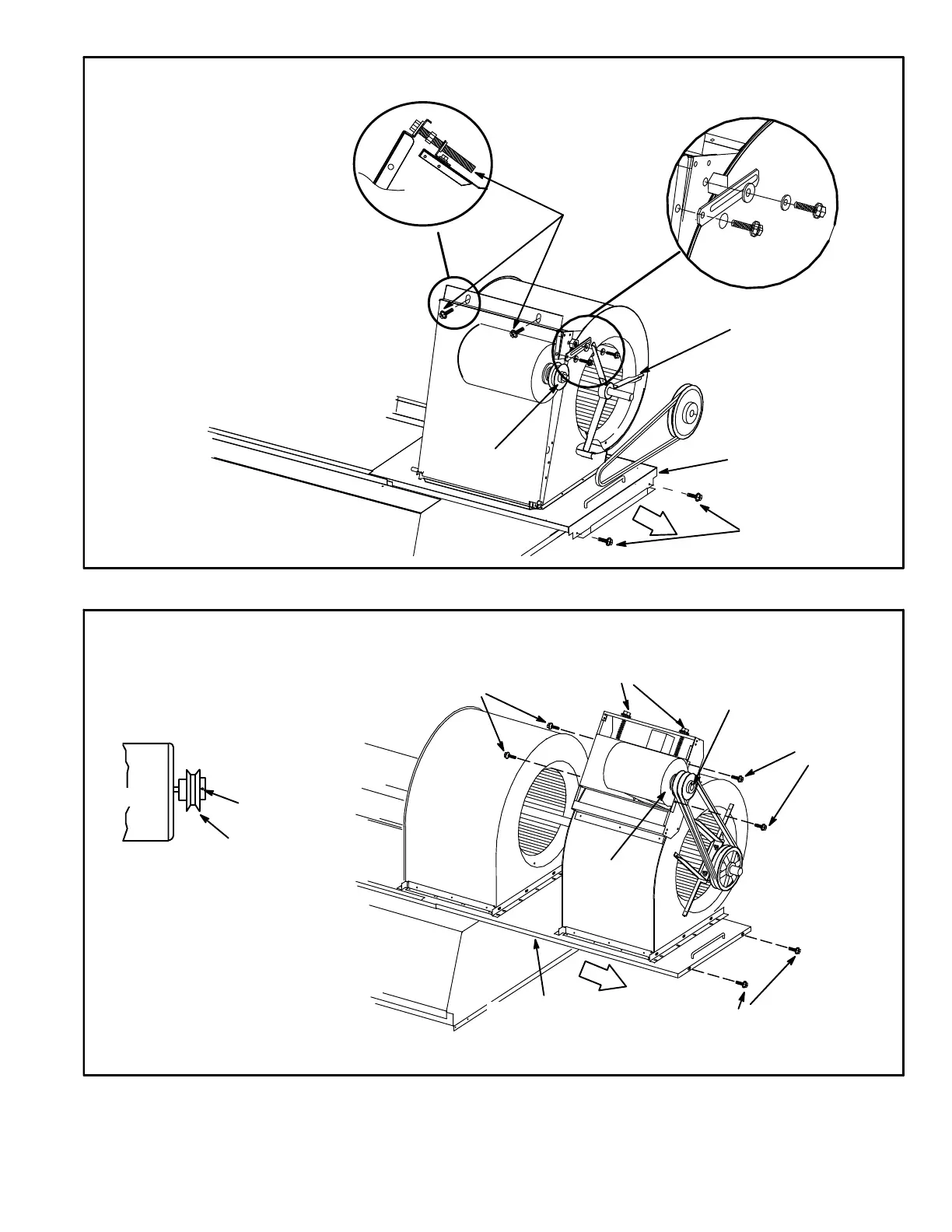

FIGURE 12

BLOWER ASSEMBLY SCA120

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

BLOWER

MOTOR

PULLEY

BLOWER ASSEMBLY

SLIDING BASE

BELT TENSION

ADJUSTING

BOLTS

BLOWER WHEEL BRACKET IS

H−STYLE ON 20− & 25−TON UNITS

REMOVE SCREWS TO

SLIDE BLOWER

ASSEMBLY OUT OF UNIT

SIDE VIEW

CAV UNITS:

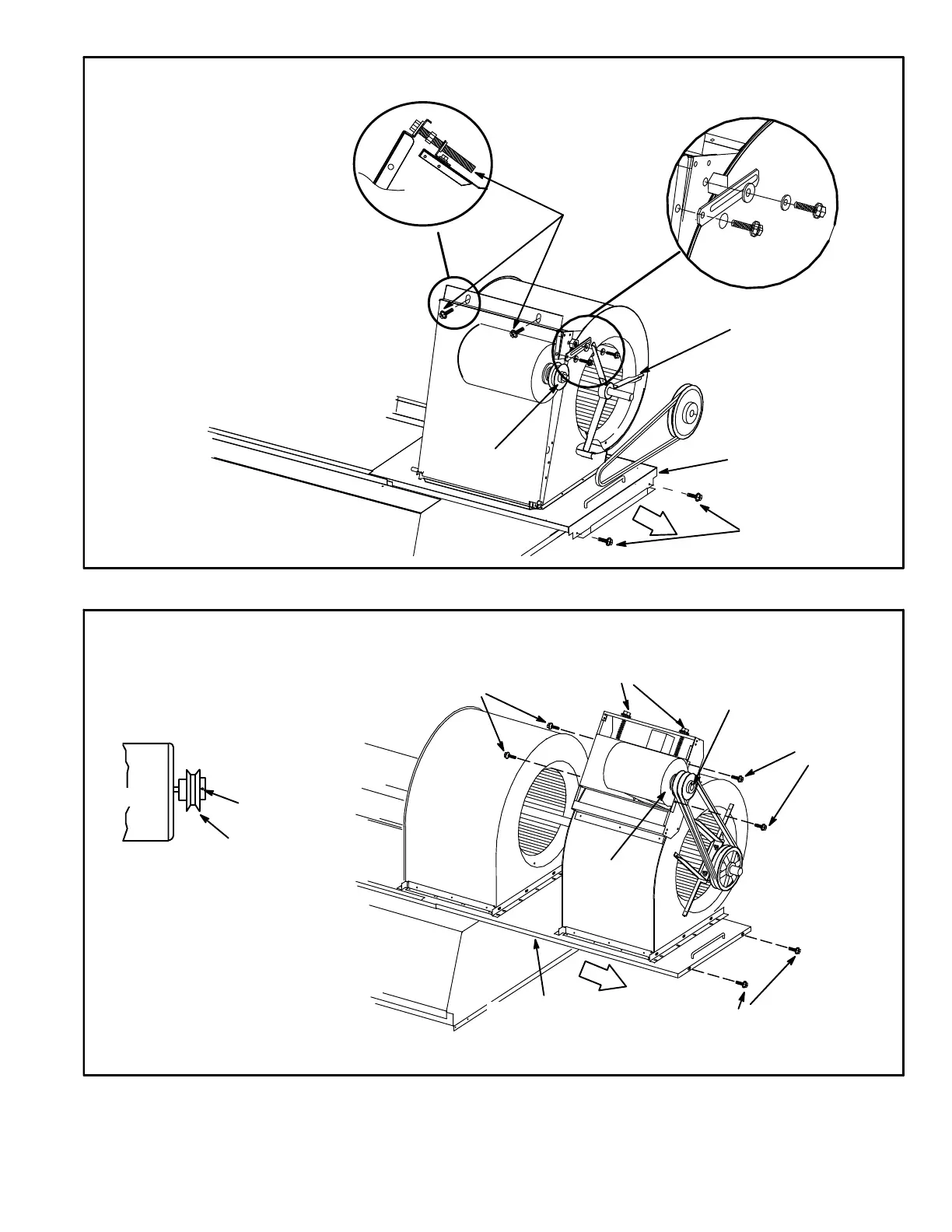

FIGURE 13

BLOWER ASSEMBLY (SCA240 & SCB288)

TO INCREASE BELT TENSION

1−Loosen four screws securing blower motor to

sliding base.

2−Turn adjusting screw to the left, or counter-

clockwise, to move the motor downward and

tighten the belt.

3−Tighten four screws.

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

LOOSEN SCREWS

TO ADJUST BELT

TENSION

BLOWER

MOTOR

REMOVE SCREWS TO SLIDE

BLOWER ASSEMBLY OUT OF UNIT

LOOSEN SCREWS TO

ADJUST BELT TENSION

PULLEY

ALLEN

SCREW

BELT TENSION

ADJUSTING SCREWS

BLOWER

ASSEMBLY

SLIDING BASE

PULLEY

MOTOR

ALLEN

SCREW

SIDE VIEW

CAV UNITS:

Loading...

Loading...