Page 30

Constant Air Volume (CAV) Blowers

4− The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley clock-

wise to increase CFM. Turn counterclockwise to de-

crease CFM. See figure 12, or 13. Do not exceed mini-

mum and maximum number of pulley turns as shown

in table 1.

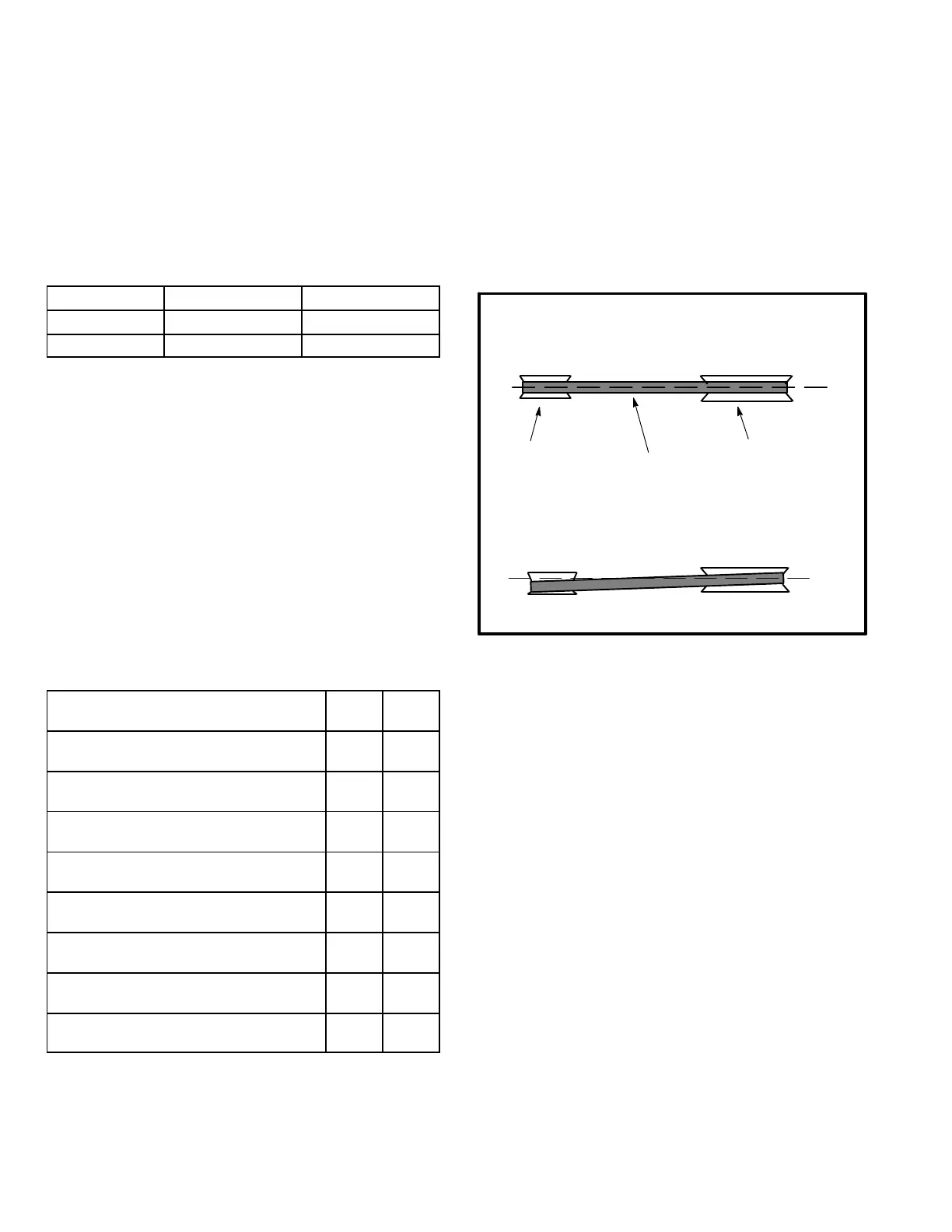

TABLE 1

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt Minimum Turns Open Maximum Turns Open

A Section 0 5

B Section 1* 6

*No minimum number of turns open when B belt is used on pulleys

6" O.D. or larger.

Multi−Stage Air Volume (MSAVt) Blowers

5− The VFD blower motor pulley is fixed. The supply CFM

can be adjusted by changing ECTO settings at the IMC

board or by using optional software. See table 2 (ex-

ample only for 240/288 units) See unit label for ECTO

setting for all units)

IMPORTANT − Units are factory−set in MSAV mode. If blow-

er speed does not change appropriately to demand, check

ECTO 0.01. Setting should be 3.

TABLE 2

240/288 FAN SPEED FACTORY ECTO SETTINGS

Example Only

Description ECTO

Factory

Setting

Sets supply air fan speed for cooling stage

1 demand.

0.05 35

Sets supply air fan speed for cooling stage

2 demand.

0.14 45

Sets supply air fan speed for cooling stage

3 demand.

0.15 60

Sets supply air fan speed for cooling stage

4 demand.

0.16 73

Sets supply air fan speed for heating stage

1 demand.

0.04 80

Sets supply air fan speed for blower only

demand.

0.03 73

Sets supply air fan speed for smoke alarm

demand (smoke detector is optional).

0.02 80

Sets supply air fan minimum speed for

cooling, ventilation, or smoke detection.

0.06 33

The minimum output CFM output for cooling, ventila-

tion or smoke alarm mode is factory−set at 33% of fan

speed. The minimum can be adjusted by ECTO 0.06:

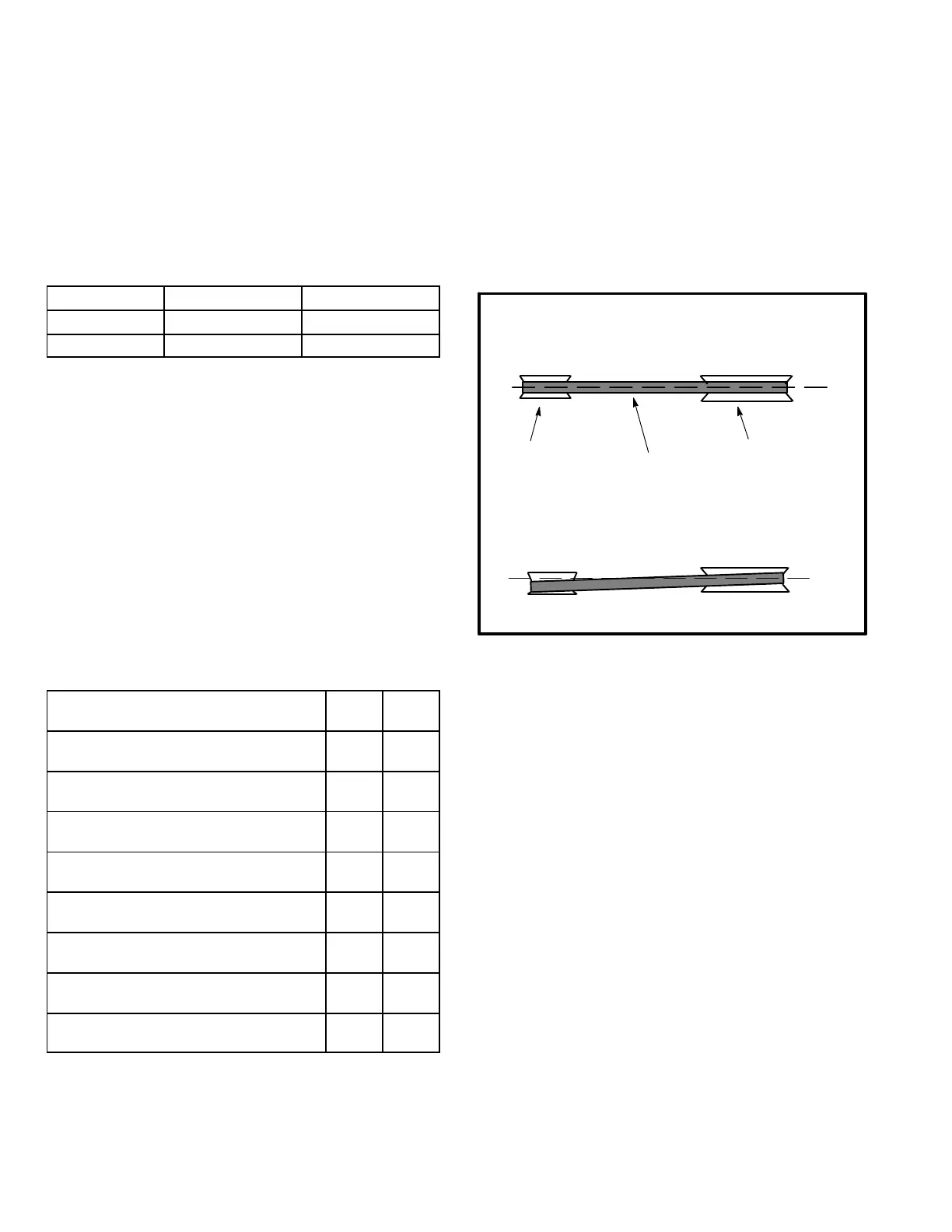

Adjust Belt Tension

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are main-

tained. Tension new belt after a 24−48 hour period of op-

eration. This will allow belt to stretch and seat to

grooves. Make sure blower and motor pulley are aligned

as shown in figure 14.

FIGURE 14

PULLEY ALIGNMENT

(TOP VIEW)

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

1− Loosen screws securing slotted arm and rear belt ten-

sion adjusting bolt. See figure 12.

2− To increase belt tension −

Turn front belt tension adjusting bolt to the left, or coun-

terclockwise, to tighten the belt. This increases the dis-

tance between the blower motor and the blower hous-

ing.

To loosen belt tension −

Turn the front belt tension adjusting bolt to the right, or

clockwise to loosen belt tension.

3− Turn rear belt tension adjusting bolt until pulleys are

aligned. Tighten screws securing slotted arm and rear

belt tension adjusting bolt once adjustments have been

made.

Check Belt Tension

Overtensioning belts shortens belt and bearing life. Check

belt tension as follows:

Loading...

Loading...