Page 19

SGH/SCH036, 060, 120, 240

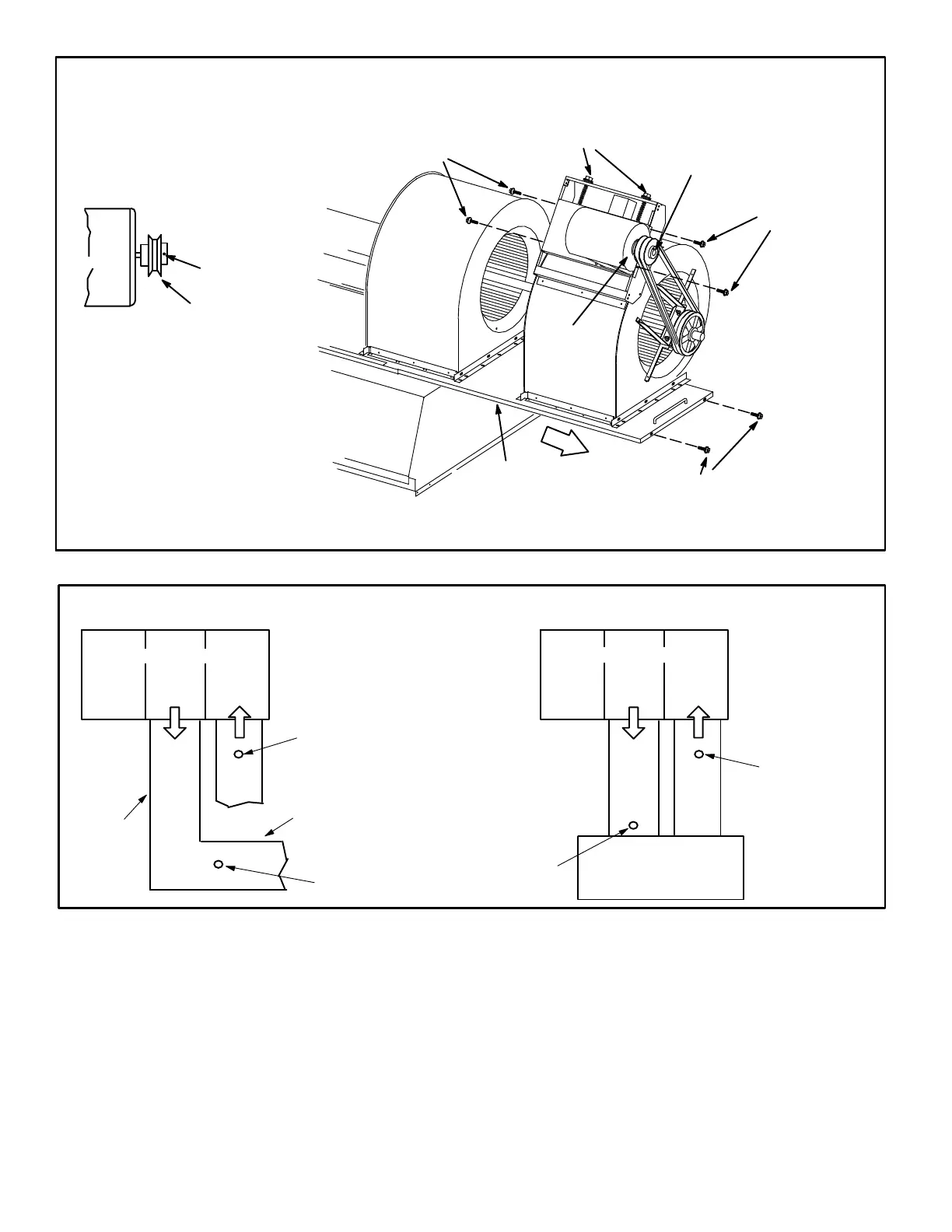

BLOWER ASSEMBLY (SG/SC 240)

TO INCREASE BELT TENSION

1-Loosen four screws securing blower motor to

sliding base.

2-Turn adjusting front and rear tension adjusting

screws to the right, or clockwise, to move the

motor upward and tighten the belt.

3-Tighten four screws.

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

LOOSEN FOUR

SCREWS TO AD

JUST BELT TENSION

BLOWER

MOTOR

REMOVE SCREWS TO SLIDE

BLOWER ASSEMBLY OUT OF UNIT

LOOSEN SCREWS TO

ADJUST BELT TENSION

PULLEY

ALLEN

SCREW

BELT TENSION

ADJUSTING SCREWS

BLOWER

ASSEMBLY

SLIDING BASE

PULLEY

MOTOR

ALLEN

SCREW

SIDE VIEW

FIGURE 23

FIGURE 24

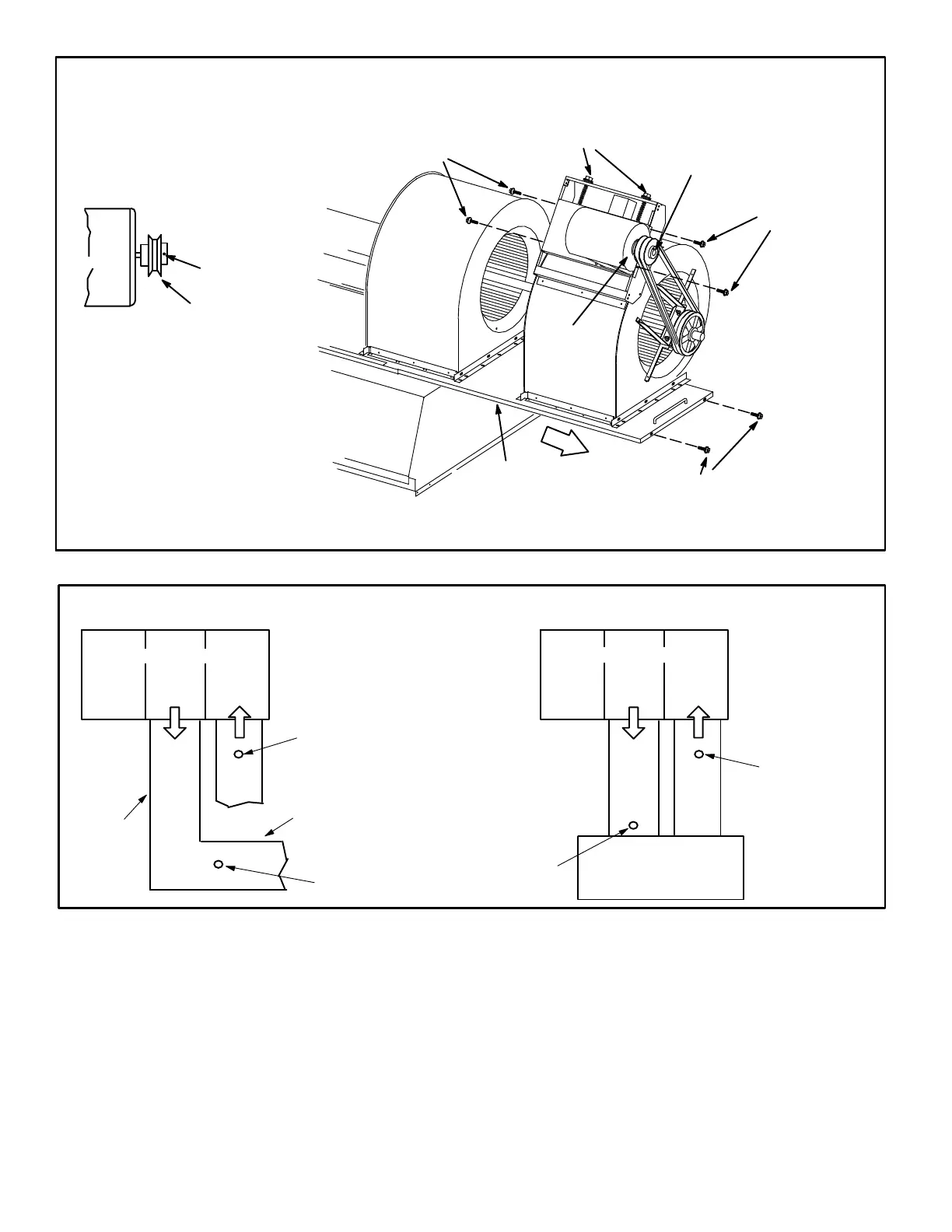

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

RE

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

RE

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

Loading...

Loading...