Page 2

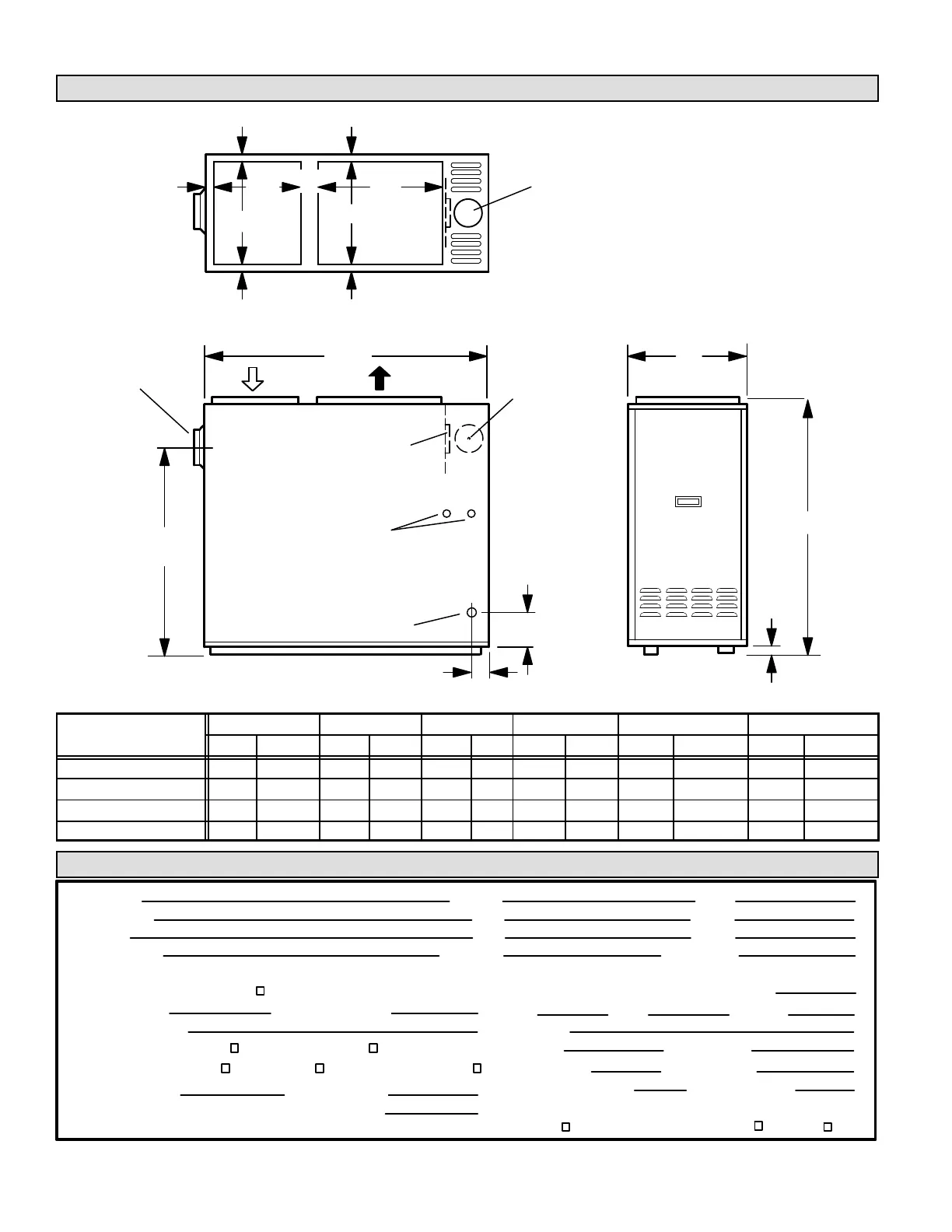

SLO185BV Unit Dimensions - Inches (mm)

FLUE CONNECTION

SLO185BR101/114V42

1

(25)

2-1/2

(64)

RETURN

AIR

OPENING

SUPPLY

AIR

OPENING

OIL PIPING INLET

(Both Sides)

ELECTRICAL INLETS

(Right Side Only)

TOP VIEW

SIDE VIEW FRONT VIEW

A

E

D

E

3/4

(19)

FLUE CONNECTION

SLO185BF101/114V42 &

SLO185B5F135/150V60

(On Heat Exchanger)

AIR FLOW

AIR FLOW

3/4

(19)

3/4

(19)

3/4

(19)

1‐1/2

(38)

3‐1/4

(83)

5-1/4

(133)

B

C

FG

SIDE

FLUE OUTLET

CENTERING HOLE

(Field-Fabricate

Either Side)

TOP FLUE

OUTLET

Model No.

A B C D E x F (Supply) E x G (Return)

in. mm in. mm in. mm in. mm in. mm in. mm

SLO185BF79/105V42 19‐1/2 495 37 940 52-1/2 1334 27 686 18 x 21 457 x 533 18 x 16 457 x 406

SLO185BR79/105V42 19‐1/2 495 37 940 52-1/2 1334 27 686 18 x 21 457 x 533 18 x 16 457 x 406

SLO185BF124/141V60 22‐1/2 572 37 940 52-1/2 1334 27 686 21 x 21 533 x 533 21 x 16 533 x 406

SLO185BR124/141V60 22‐1/2 572 37 940 52-1/2 1334 27 686 21 x 21 533 x 533 21 x 16 533 x 406

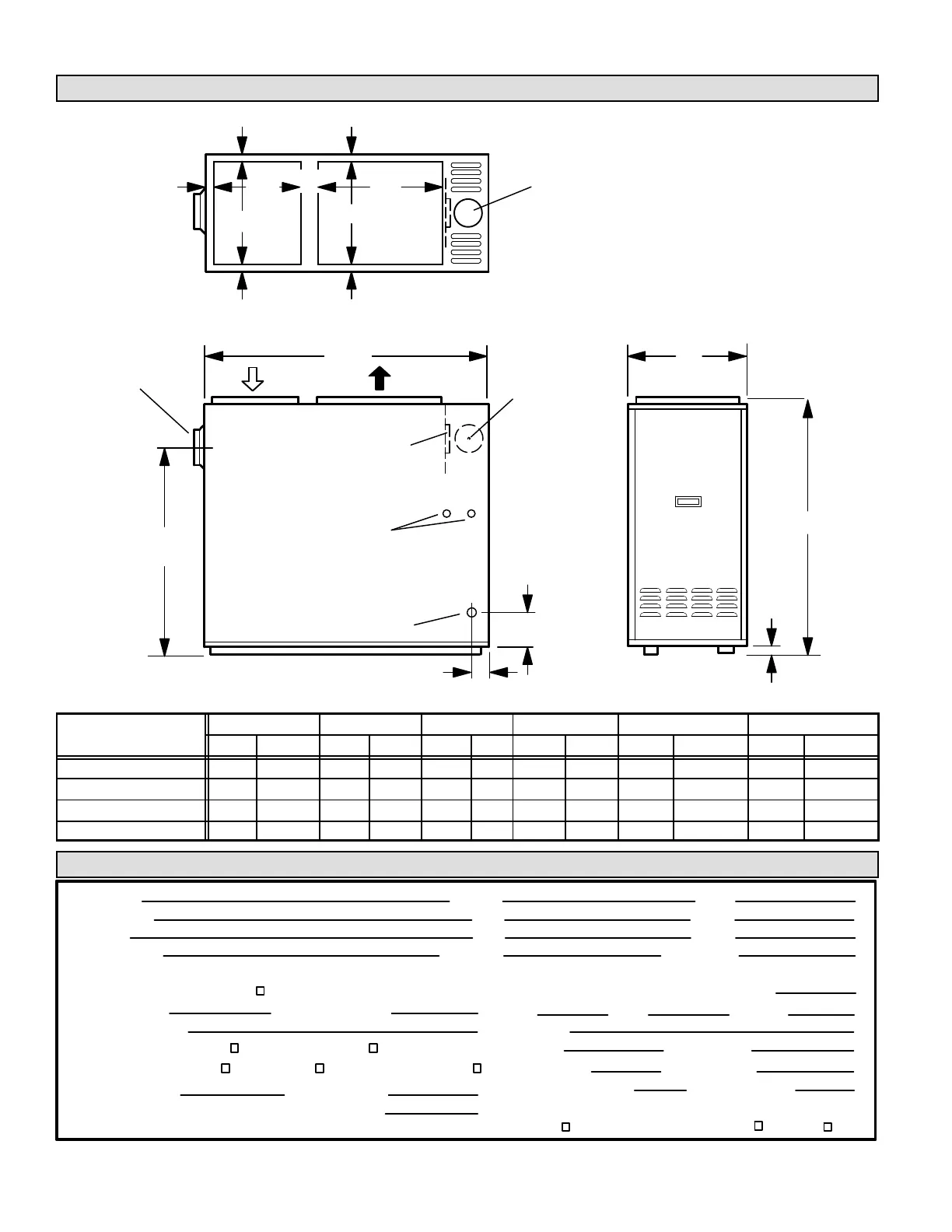

SLO185BV Start-Up & Performance Check List

Filter Clean & Secure?

Supply Voltage

Electrical Connections Tight?

Job Name

Job Location

Installer

Unit Model No.

Oil Pump Pressure [recommended minimum 140 psi]

Job No.

City

City

Serial No.

Date

State

Serviceman

Draft Reading (recommended .03-.04 inches w.c.)

Flue Connections Tight?

HEATING SECTION

THERMOSTAT

Calibrated? Heat Anticipator Properly Set? Level?

Blower Motor Amps

Blower Motor H.P.

Piping Connections Tight?

Vent Clear?

State

Temperature RiseExternal Static Pressure

Net Stack Temp

Burner Model No.

Serial Number

All Valves Open?

PROPER DRAFT

% CO

2

% O

2

ppm CO

Stack Draft Overfire Draft

Ambient Temp

Smoke Test

Loading...

Loading...