Page 20

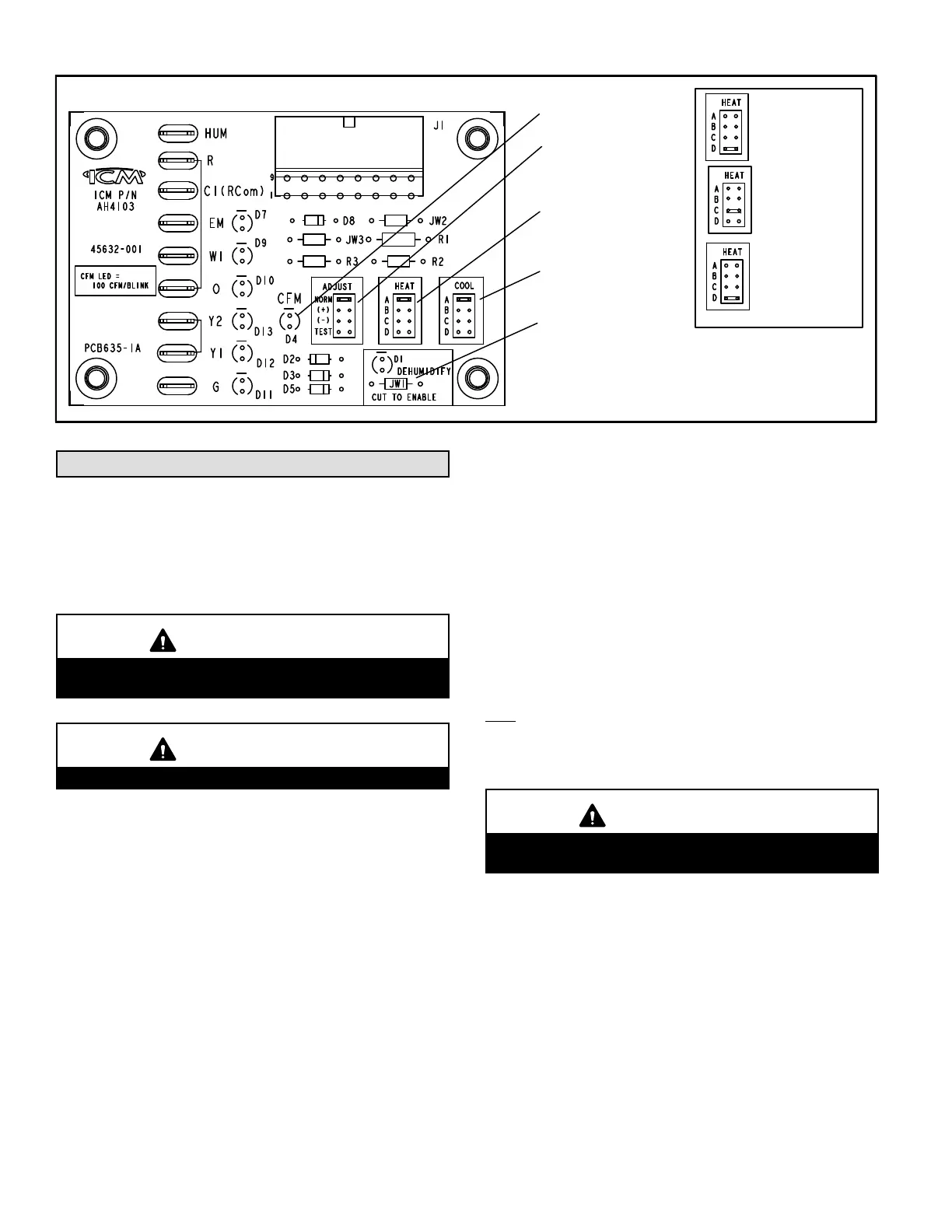

Blower Control (A54)

Figure 19

16-PIN PLUG

(BOARD TO MOTOR)

CFM LED

ADJUST

SELECTOR PINS

(Setting affects

cooling only)

HEATING SPEED

SELECTOR PINS (SEE

TABLE)

COOLING SPEED

SELECTOR PINS

NOTE - The JW1 resistor

must be cut to activate the

HUM terminal.

SLO185B-79

SLO185B-105

HEAT SPEED PINS

(JUMPERS)

NOTE - Do NOT move

heat speed jumpers

from factory settings.

SLO185BR-124

SLO185BF-124

SLO185BF-141

SLO185BR-141

Start-Up & Adjustment

Before starting unit, make sure the oil tank is adequately

filled with clean No. 1 or No. 2 furnace oil.

NOTE - Water, rust or other contaminants in oil supply sys

tem will cause malfunction and failure of the internal parts

of the fuel unit.

CAUTION

Never burn garbage or paper in the heating system.

Never leave papers near or around the unit.

CAUTION

Blower access door must be in place before start‐up.

Burner Start-Up

1 - Set thermostat for heating demand and turn on electri

cal supply to unit.

2 - Open all shut-off valves in the oil supply line to the

burner.

3 - While the ignition is on, press and release the reset

button on the burner control (hold 1/2 second or less).

If the control has not locked out since its most recent

complete heat cycle, the lockout time will be extended

to 4 minutes and the ignition will remain on for the en

tire heat cycle.

4 - Bleed the pump until all froth and bubbles are purged.

The bleed port is located on the bottom of the fuel

pump. To bleed, attach a clear plastic hose over the

vent plug. Loosen the plug and catch the oil in an

empty container. Tighten the plug when all the air has

been purged.

NOTE - A two-line fuel system will normally bleed itself

by forcing air back to the tank through the return line.

This type of bleeding procedure is not necessary.

5 - If burner fails to start within the set time, the burner

control will lock out operation. Press the reset button to

reset the control as in step 3. See figure 2 on page 3 for

burner parts arrangement.

NOTE - The reset button can be held for 15 seconds

for the Beckett 7505B primary control, at any time to

reset the controls lockout counter to zero and send the

control to standby.

CAUTION

Do not push the reset button on the primary control

more than one time.

6 - Repeat steps 4 and 5, if necessary, until pump is fully

primed and oil is free of bubbles. Then, terminate the

call for heat. The burner control will resume normal op

eration

Fuel Pump Pressure Adjustment

Measure fuel pump pressure with unit off. Attach pressure

gauge to pump outlet. Turn unit on and check pressure and

compare to table 9. Adjust if necessary.

Loading...

Loading...