Page 21

Temperature Rise Adjustment

To measure temperature rise, place plenum thermometers

in warm air and return air plenums. Locate thermometer in

warm air plenum where thermometer will not “see” the heat

exchanger to prevent it from picking up radiant heat. Set

thermostat to its highest setting to start unit. After plenum

thermometers have reached their highest and steadiest

readings, subtract the readings. The difference in tempera

tures in the supply and return air plenums should approxi

mate the temperatures listed in table 8 and on the ap

pliance rating plate.

If the temperature rise is not within the range listed, check

the following items:

D Make sure that properly sized nozzle has been

used (table 9).

D Make sure that fuel pump pressure is correct.

D If furnace is in cutback mode, check for:

Dirty filters,

Dirty indoor coil,

Restricted ducts, closed registers, etc.

Table 8

Temperature Rise

Unit Temperature Rise °F

SLO185BV799 45 - 55

SLO185BV105 45 - 55

SLO185BV124 55 - 65

SLO185BV141 55 - 65

Limit Control

Limit Control — Do not adjust from factory setting.

Burner Adjustment

The following instructions are essential to the proper op

eration of SLO185BV series oil furnaces. Refer to table 9

for nozzle and pump pressure information. The proper way

to adjust an oil burner is with a CO

2

analyzer and smoke

gun. A properly adjusted burner will result in a quiet, clean

fire which will prevent sooting and minimize cleaning. Us

ing the following procedure will provide a margin of reserve

air to accommodate variable conditions.

1. Punch a 5/16” diameter service hole in the flue outlet.

This sampling hole should be at least two flue diamet

ers above the breech, or elbow at the breech, but

ahead of the barometric damper.

2. Operate burner for approximately 5 to 10 minutes.

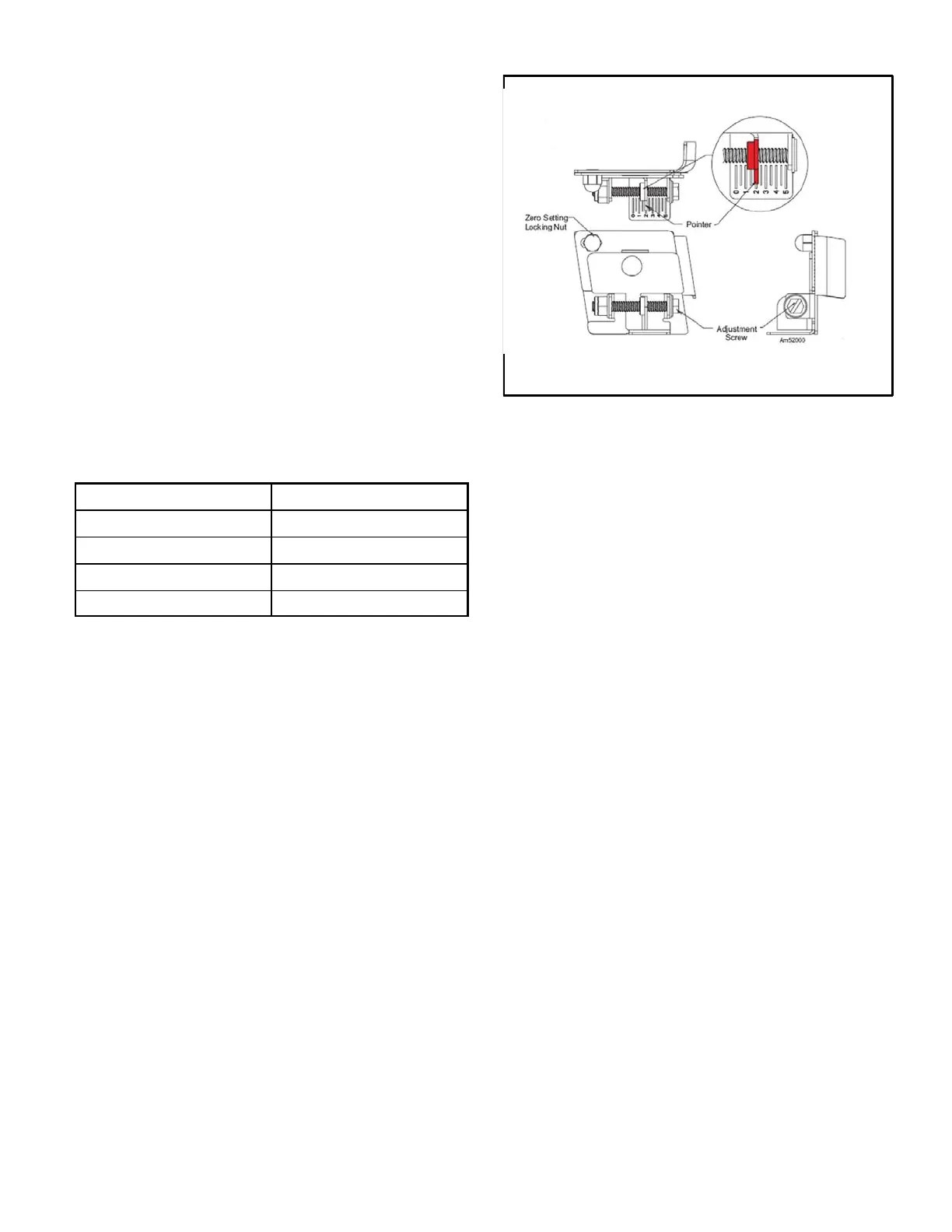

Beckett Oil Burner Nozzle Adjustment

Figure 20

3. Take a draft reading at the service hole in the flue out

let. Adjust barometric draft control in the stack to

achieve an overfire draft of -0,1” to -.02” and a breach

of -0.2 to -.04”.

4. Pull and record a smoke reading at the service hole us

ing an industry standard smoke tester.

5. If the burner is producing more than #1 smoke, adjust

the intake air using the zero setting locking nut and ad

justment screw (figure 20). Loosen the locking nut ap

proximately one turn. Turn the adjustment screw clock

wise to increase air or counterclockwise to decrease

air.

6. Once the desired smoke level is achieved, use a suit

able test instrument and take a CO

2

sample at the ser

vice hole in the flue outlet (from step1).

7. Adjust the air from step 5 to achieve the desired CO2

level.

8. Recheck smoke level.

9. Recheck draft and CO

2

reading at the service hole.

10. Using a suitable thermometer, obtain and record the

flue gas temperature at the service hole.

11. Use the CO

2

reading and the flue gas temperature

reading to determine unit efficiency.

12. When proper combustion and smoke readings have

been achieved, tighten the zero setting lock nut and

adjustment screw.

Loading...

Loading...