Page 22

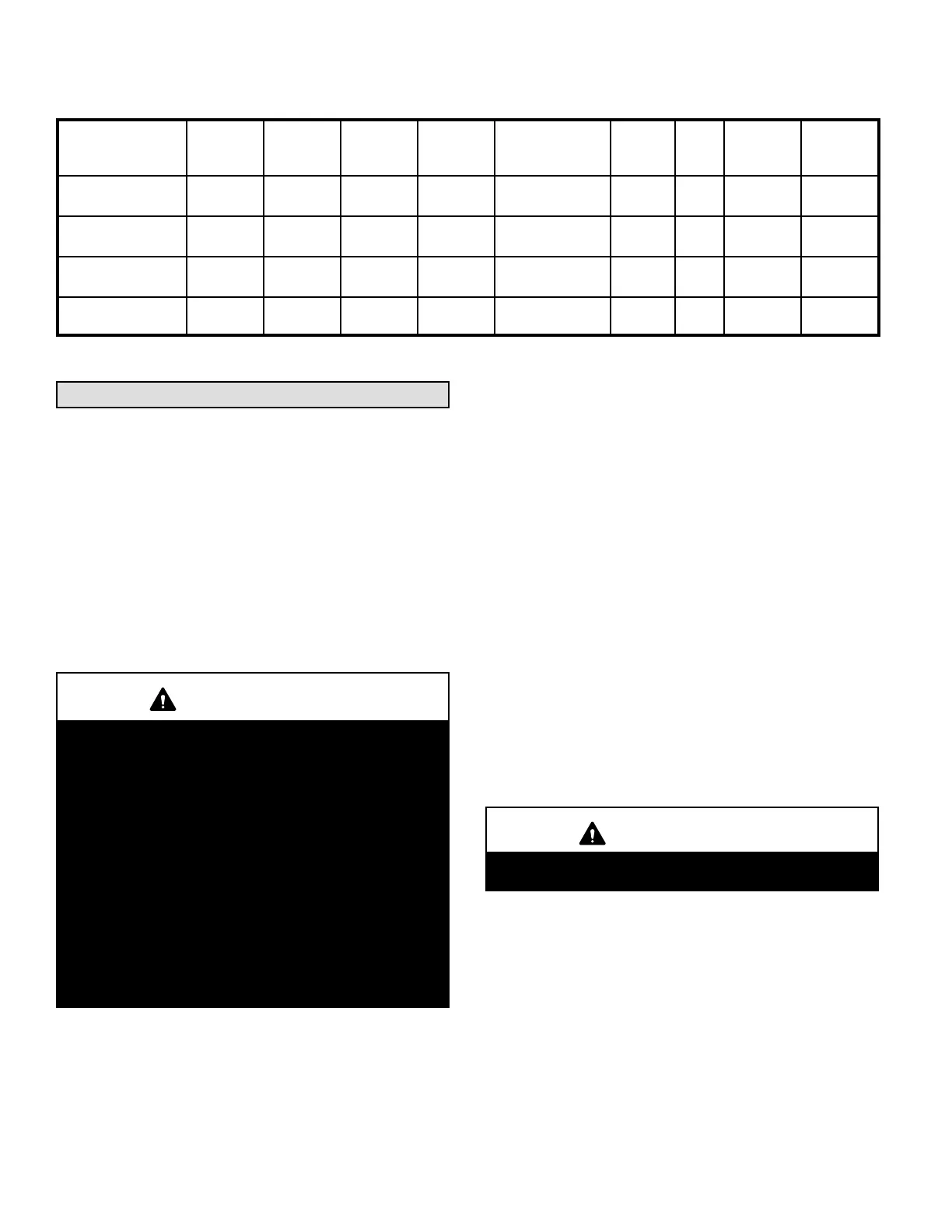

Table 9

Burner Specifications

Unit

Burner

Number

Beckett

Spec. No.

Beckett

Air Tube

Part No.

Input

Rating

BTU/HR

Nozzle Size,

Spray, Angle, &

Pattern

Pump

Pres

sure

Head

Insertion

Length

Static

Plate

Diameter

SLO185BV-79/105 103880-01 ARM2201 NX70LHHS 79,000

0.50gph x 60°A

hollow

150 6 Slot 5” 3.00”

SLO185BV-79/105 103880-01 ARM2201 NX70LHHS 105,000

*0.65gph x 60 °A

hollow

150 6 Slot 5” 3.00”

SLO185BV-124/141 103880-02 ARM2202 NX70LCHS 124,000

0.75gph x 60°A

hollow

145 6 Slot 5” 3.25”

SLO185BV-124/141 103880-02 ARM2202 NX70LCHS 141,000

*0.85gph x 60°A

hollow

145 6Slot 5” 3.25”

*Nozzle must be field-installed for conversion to higher heating input.

NOTE - All nozzles are Delavan brand.

Service

A - Servicing Filter

NOTE - Under no circumstances should the access panels

to the blower compartment be left off or left partially open.

1 - Throw‐Away Type Filters — Filters should be checked

monthly and replaced when necessary to assure prop

er furnace operation. Replace filters with like kind and

size filters.

2 - Reusable Type Filters — Filters should be checked

monthly and cleaned when necessary to assure prop

er furnace operation. Use warm water and a mild de

tergent. Replace filter when dry. Permanent filters

supplied with SLO185B furnaces do not require oiling

after cleaning. Examine filter label for any for special

instructions that may apply.

IMPORTANT

If a highefficiency filter is being installed as part of

this system to ensure better indoor air quality, the fil

ter must be properly sized. Highefficiency filters

have a higher static pressure drop than standardef

ficiency glass/foam filters. If the pressure drop is too

great, system capacity and performance may be re

duced. The pressure drop may also cause the limit to

trip more frequently during the winter and the indoor

coil to freeze in the summer, resulting in an increase

in the number of service calls.

Before using any filter with this system, check the

specifications provided by the filter manufacturer

against the data given in the appropriate Lennox

Product Specifications bulletin. Additional informa

tion is provided in Service and Application Note

ACC002 (August 2000).

B - Blower

Blower motor is pre‐lubricated and sealed for extended op

eration. No further lubrication is required. Disconnect pow

er to unit before cleaning blower wheel for debris.

C - Flue Pipe Inspection

The flue pipe should be inspected annually by a qualified

service technician. Remove and clean any soot or ash

found in the flue pipe. Inspect pipe for holes or rusted

areas. If replacement is necessary, replace with the same

size and type as required by code. Inspect the flue baro

metric draft control and replace if found to have failed.

D - Cleaning Heat Exchanger

1 - Remove the vent pipe from the furnace.

2 - Remove the locking screws and the caps from the

clean out tubes. Remove flue access elbow.

3 - Using a long spiral wire brush, sweep down the outer

drum of the heat exchanger. Then using the hose at

tachment, vacuum out loose debris.

4 - Remove the locking screw and cap from the observa

tion tube and with the spiral wire brush, reach upward

toward the rear of the heat exchanger to clean out the

crossover tube.

CAUTION

Do not attempt to clean the combustion chamber. It

can be easily damaged.

5 - Replace the clean out caps and flue access elbow.

Make sure locking screws are secure.

6 - Brush out and vacuum the vent outlet area of the outer

drum and replace vent pipe.

7 - Clean around burner, blower deck and vestibule area.

NOTE - A heat exchanger clean‐out kit ABRSH380

(35K09) is available from Lennox. The kit includes a ra

diator brush, a tapered brush and a non-metallic 36”

spiral wire handle.

Loading...

Loading...