Page 7

2 - Level the unit from side-to-side and from front-to-rear.

If the furnace is not level, place fireproof wedges or

shims between the low side of the furnace and the

floor. Make sure the weight of the furnace is distributed

evenly on all four corners. Strain on sides of cabinet

may occur if furnace weight is not evenly distributed.

This strain can cause cracking and popping noises.

Adjustments

Neither the nozzle setting nor the air adjustments are facto

ry set. The furnace is fire-tested and the limit control is

checked to make sure it functions properly; no factory set

tings are made. During installation, the furnace must be ad

justed to ensure proper operation. The installing dealer/

contractor must have and use proper test equipment in

order to correctly adjust the oil furnace. Proper testing

equipment is required to ensure correct operation of the

unit. The use of test equipment is more critical than ever

due to tighter tolerances needed to keep the furnace oper

ating efficiently.

Among the required test equipment for an oil furnace, the

proper combustion test kit should contain the following:

D Draft gauge

D CO

2

or O

2

Analyzer

D Smoke tester

D Pressure gauge

D High temperature thermometer

D Oil vacuum gauge

D Beckett T-501 nozzle gauge

D Knowledge of proper test equipment operation

CAUTION

Improper nozzle and/or air adjustment of this unit

may result in sooting problems. Refer to the follow

ing section for correct adjustment procedures.

Nozzle Adjustment

Proper adjustment of the nozzle assembly is critical. Before

the flue pipe and oil lines are installed, the nozzle assembly

must be checked for proper depth and alignment. You must

remove the entire burner assembly (not just the nozzle) from

the furnace to check the nozzle depth and alignment. The

smaller sized firing nozzle has been factory-installed. This

should be verified by the installer. A larger nozzle has been

provided in the bag assembly for use with SLO185BV105

and 141 units. Inspect the spark transformer leads also to en

sure they are still attached to the electrodes.

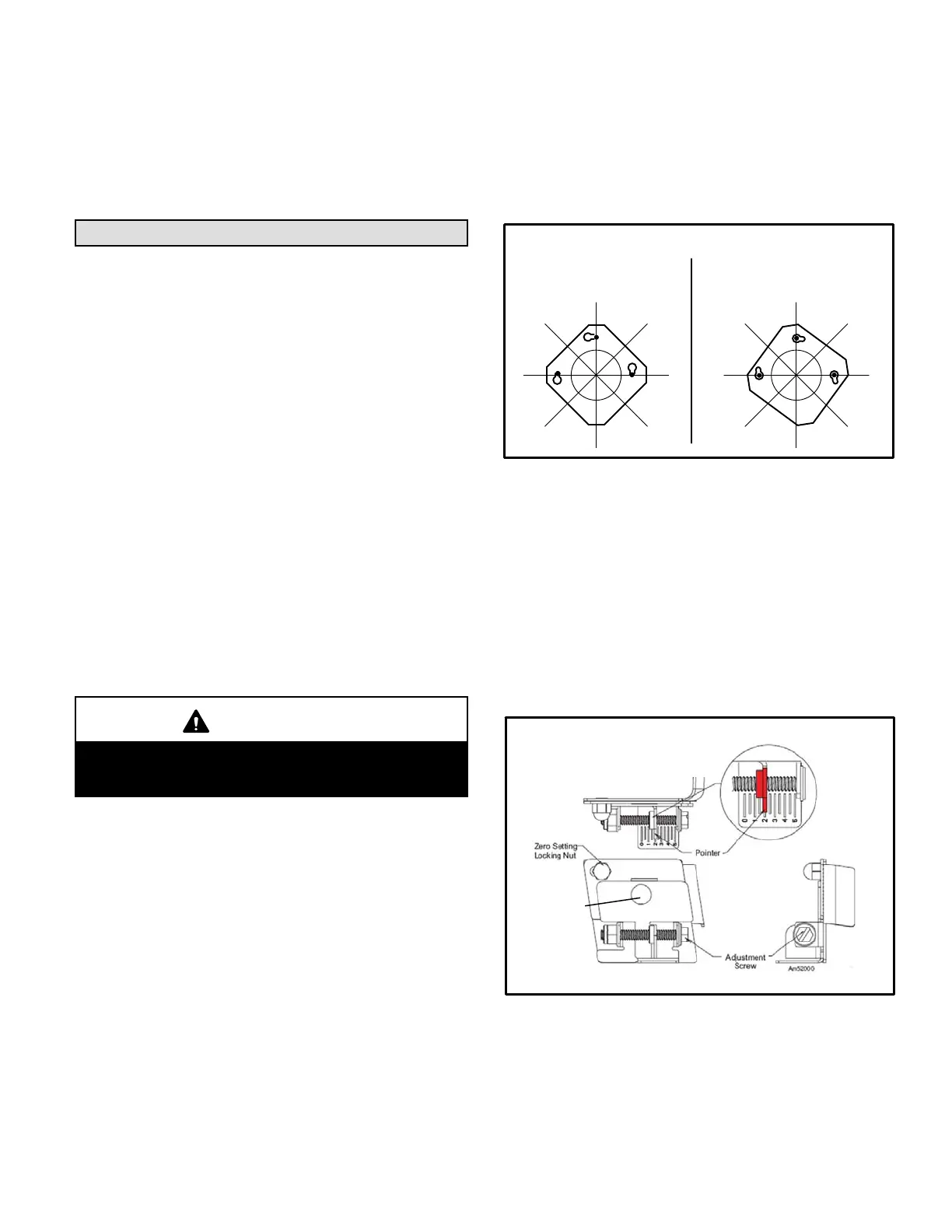

The burner assembly is attached to the vestibule panel by

three nuts. Slots are provided in the mounting flange for re

moving the burner assembly from the vestibule. Loosen the

nuts and turn the whole burner assembly clockwise (figure

6) to remove the entire burner assembly from the furnace.

There is adequate wire to remove the burner without discon

necting wires. Once removed, turn the burner around in the

vest panel area.

Figure 6

SLO185BV Series Burner Removal

First, loosen three nuts which

attach burner to vest panel.

Next, rotate burner clockwise

on slots then pull toward you.

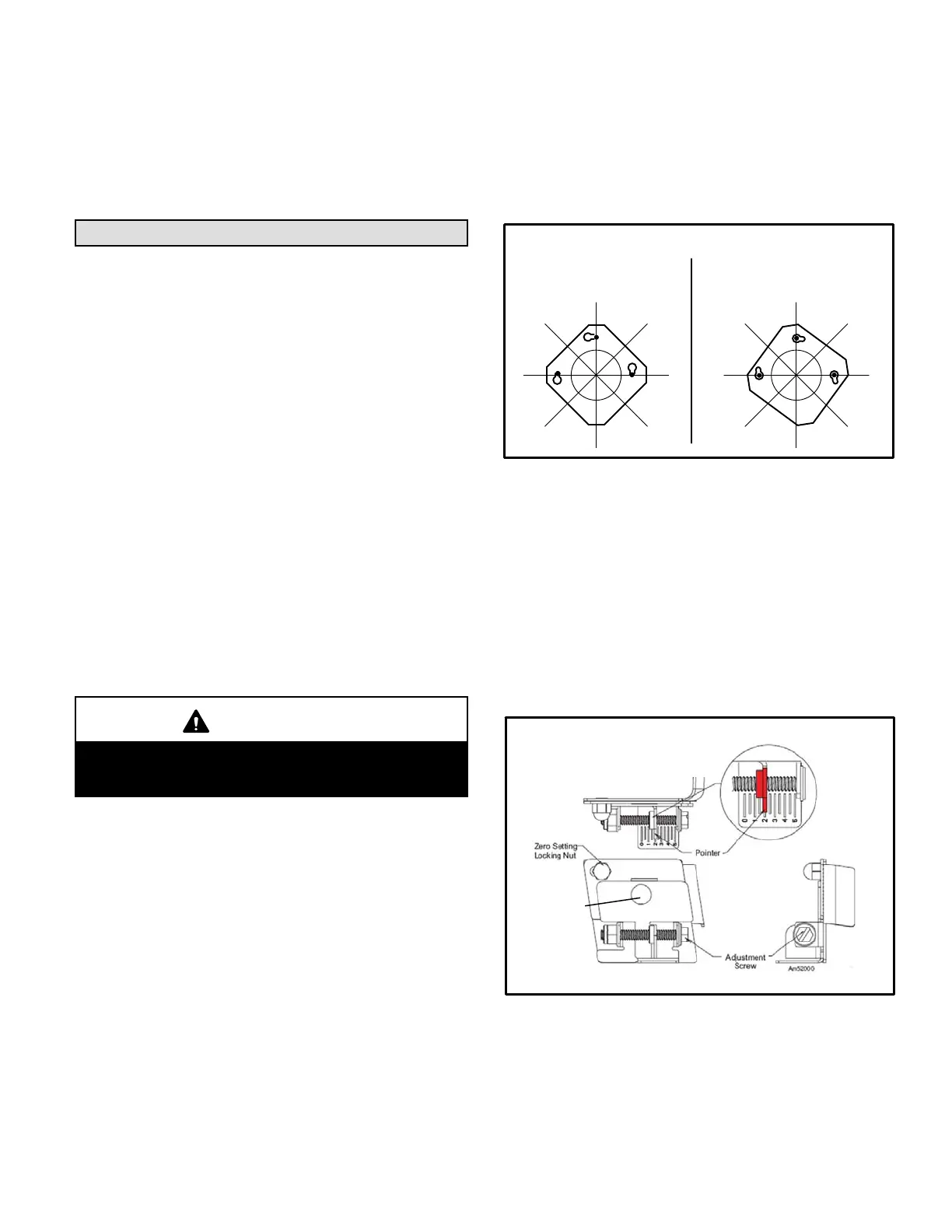

To check the ignition electrode gap use the T-501 gauge.

The proper gap should be 5/32”.

To check nozzle alignment, again insert the small end of

gauge into the end cone and measure the nozzle and

electrode alignment against the center lines marked on

the gauge (again refer to enclosed illustration sheet). If

the nozzle is not centered, but found to be too far left or

right, a new nozzle assembly will need to be ordered. Do

not attempt to adjust by bending the 90 degree elbow in

the oil line.

Take care to properly re-install burner assembly when

nozzle adjustment has been completed.

Figure 7

Beckett Oil Burner Nozzle Adjustment

Burner must be removed from

furnace for this procedure.

Splined Nut

Loading...

Loading...