Page 11

Discharge Air Temperature Sensor

This furnace is shipped with a discharge air temperature sensor that can be installed in the supply air plenum. The sen-

sor is used to measure temperature rise in the heating mode and temperature drop in the cooling mode. See TABLE 2

and FIGURE 15 (upow) or TABLE 3 and FIGURE 16 (horizontal left) or TABLE 4 and FIGURE 17 (horizontal right) for

correct location. Drill a 3/8 inch diameter hole in the supply duct based on the specied location. Center the discharge

air temperature sensor in the middle of the hole and use two eld provided screws to secure in place. The orientation of

the sensor mounting ange is not critical and can be oriented to whatever position is needed to prevent interference with

the evaporator coil, air duct etc. Field supplied wiring must be used to connect the discharge air temperature sensor to

the discharge air temperature sensor terminals on the integrated control board. Either wire can be connected to either

terminal. See FIGURE 18.

A communicating thermostat can be used to run temperature rise and temperature drop tests and viewed in the installa-

tion reports. See “FIGURE 53” on page 36 for communicating thermostat wiring. If a communicating thermostat is not

being used, then the discharge temperature can be viewed on the seven segment LED on the integrated control shown in

FIGURE 18. For zoning applications the discharge air sensor must be installed and wired to the zoning control board and

should not be wired to the furnace control board.

NOTE - The discharge air temperature sensor must be located per TABLE 2, TABLE 3 or TABLE 4 to provide an accurate

temperature measurement.

NOTE - If the system does not include an evaporation coil, the sensor should be installed according to the following:

1 - Place the sensor as far away from the direct heat source in the main plenum as possible. A minimum of 19” is recom

mended but up to 36” is preferred.

NOTE - If the system does not include an evaporation coil, the sensor should be installed according to the following:

1 - Place the sensor as far away from the direct heat source in the main plenum as possible. A minimum of 19” is recom

mended but up to 36” is preferred.

2 - Oset the sensor 1/4 of the width of the plenum from the left edge of the plenum in upow, top edge of the plenum in

horizontal right and bottom of the plenum in horizontal left. For example, if the plenum is 16” wide then oset the sensor 4”

from the edge. The sensor should report a temperature within the rise range of the furnace. If the readings from the sensor

appear to be below the rise range of the furnace, move the sensor in 1” increments towards the center of the plenum until

the sensed temperature is within the rise range of the furnace. If the sensor reading appears to be too high, move the sen-

sor in 1” increments towards the edge of the plenum until the sensed temperature is within the rise range of the furnace.

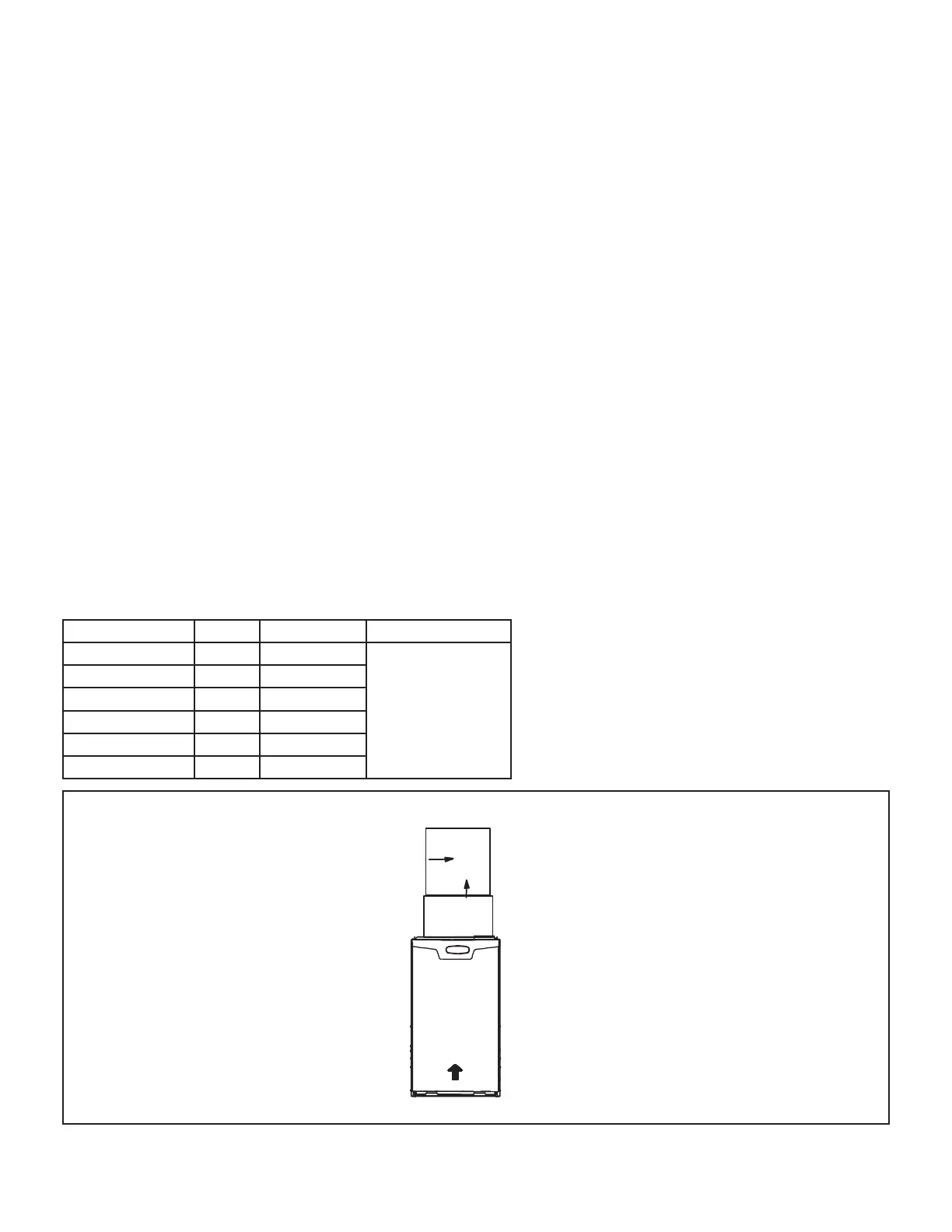

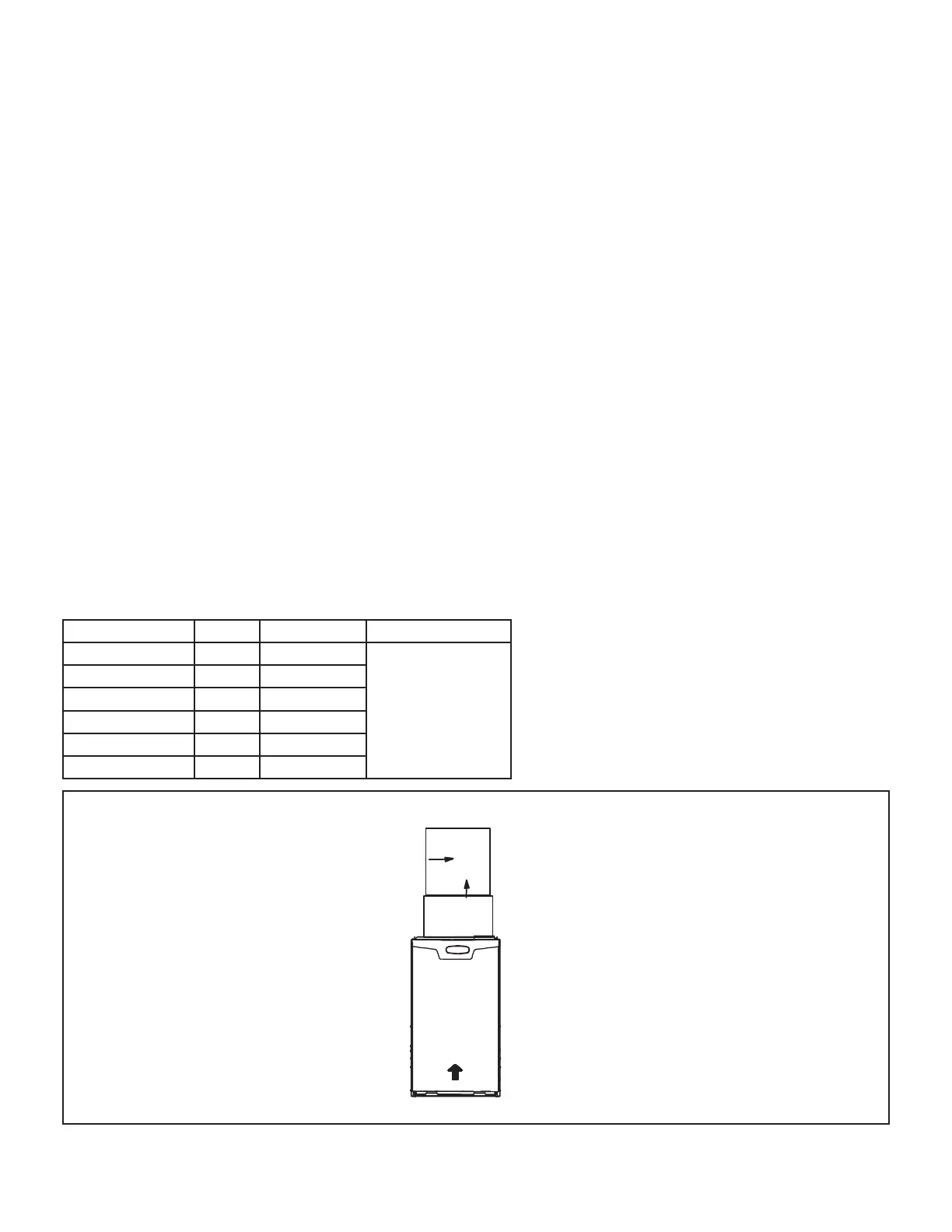

TABLE 2

Discharge Air Temperature Sensor Location Upow

SLP99UH Model “a” “b” Mounting Surface

070XV36B 2” Center

Plenum

Duct

090XV36C 3” Center

090XV48C 2” 7” from right

090XV60C 3” 4” from left

110XV60C 2” 8” from right

135XV60D 2” 7” from left

Coil

Plenum

a

b

Upflow

AIR FLOWAIR FLOW

Discharge Air Temperature Sensor Location

FIGURE 15

Loading...

Loading...