Page 13

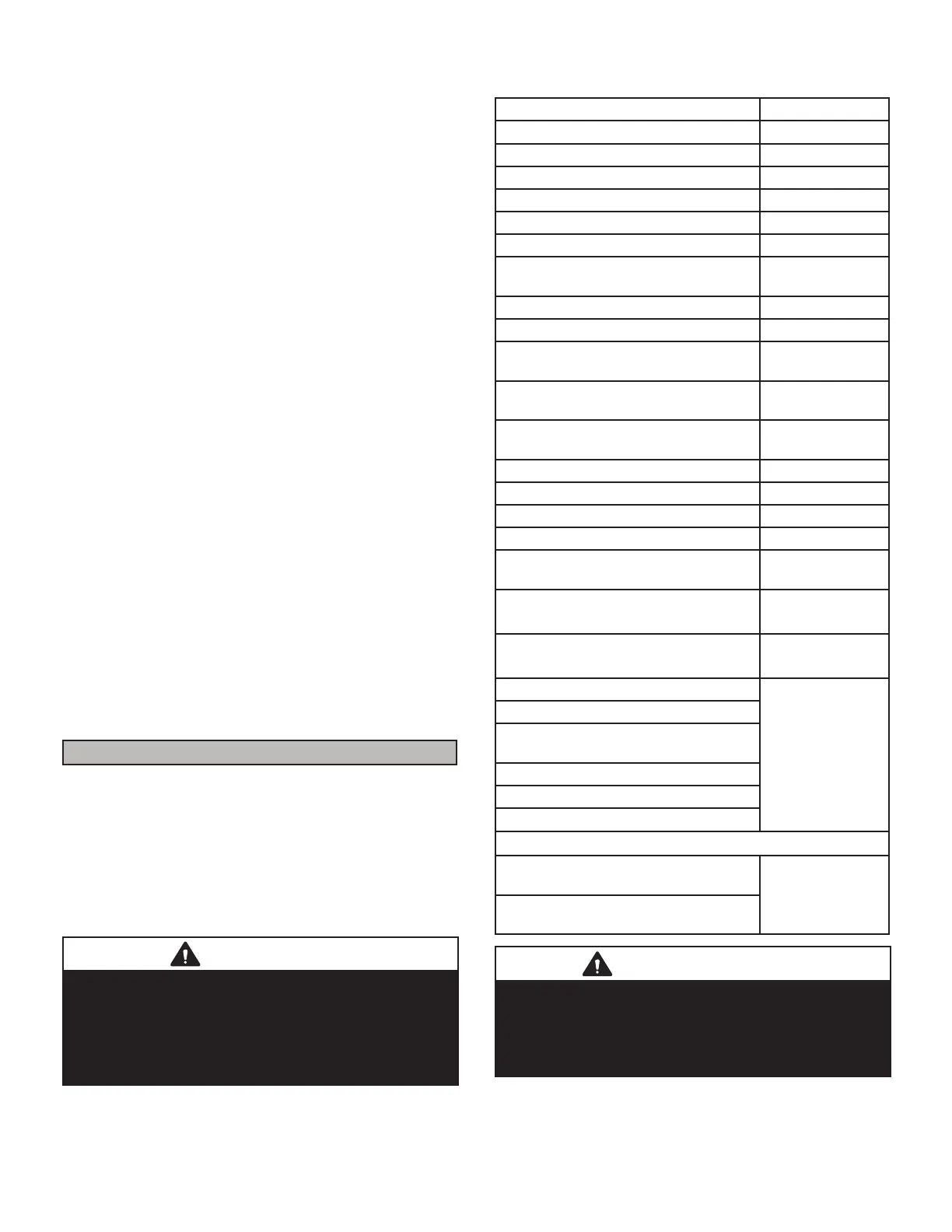

TABLE 5

PIPING AND FITTINGS SPECIFICATIONS

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

Schedule 40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR-21 PVC or SDR-26 PVC (Pipe) D2241

SDR-21 CPVC or SDR-26 CPVC (Pipe) F442

Schedule 40 ABS Cellular Core DWV

(Pipe)

F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent) (Pipe &

Fittings)

D2661

PVC-DWV (Drain Waste & Vent) Pipe &

Fittings)

D2665

PRIMER & SOLVENT CEMENT

ASTM

SPECIFICATION

PVC & CPVC Primer F656

PVC Solvent Cement D2564

CPVC Solvent Cement F493

ABS Solvent Cement D2235

PVC/CPVC/ABS All Purpose Cement

For Fittings & Pipe of the same material

D2564, D2235,

F493

ABS to PVC or CPVC Transition Solvent

Cement

D3188

CANADA PIPE & FITTING & SOLVENT

CEMENT

MARKING

PVC & CPVC Pipe and Fittings

ULCS636

PVC & CPVC Solvent Cement

ABS to PVC or CPVC Transition

Cement

POLYPROPYLENE VENTING SYSTEM

PolyPro® by Duravent

InnoFlue® by Centrotherm

UL 1738 CERTIFIED GAS VENTING SYSTEM

IPEX System1738 Schedule 40 PVC

Pipes and Fittings

UL1738

IPEX System1738 PVC FGV Cement &

Primer

IMPORTANT

SLP99UHV exhaust and intake connections are made

of PVC. Use PVC primer and solvent cement when

using PVC vent pipe. When using ABS vent pipe, use

transitional solvent cement to make connections to the

PVC ttings in the unit.

NOTE - Operation of this furnace in heating mode (indoor

blower operating at selected heating speed) with an ex-

ternal static pressure which exceeds 0.8 inches w.c. may

result in erratic limit operation.

Supply Air Plenum

If the furnace is installed without a cooling coil, a remov-

able access panel should be installed in the supply air

duct. The access panel should be large enough to permit

inspection (by reected light) of the heat exchanger for

leaks after the furnace is installed. If present, this access

panel must always be in place when the furnace is oper-

ating and it must not allow leaks into the supply air duct

system. In horizontal units, install self tapping screws in

the three evaporator coil screw holes made for upow ap-

plications to seal the top cap to the vestibule panel.

Return Air Plenum

Return air must not be drawn from a room where this fur-

nace, or any other gas-fueled appliance (i.e., water heat-

er), or carbon monoxide-producing device (i.e., wood re-

place) is installed. When return air is drawn from a room,

a negative pressure is created in the room. If a gas appli-

ance is operating in a room with negative pressure, the

ue products can be pulled back down the vent pipe and

into the room. This reverse ow of the ue gas may re-

sult in incomplete combustion and the formation of carbon

monoxide gas. This toxic gas might then be distributed

throughout the house by the furnace duct system.

Return air can be brought in through the bottom or either

side of the furnace (return air brought in through either

side of the furnace allowed in upow applications only). If

a furnace with bottom return air is installed on a platform,

make an airtight seal between the bottom of the furnace

and the platform to ensure that the unit operates proper-

ly and safely. Use berglass sealing strips, caulking, or

equivalent sealing method between the plenum and the

furnace cabinet to ensure a tight seal. If a lter is installed,

size the return air duct to t the lter frame.

Pipe Fittings Specications

All pipe, ttings, primer and solvent cement must conform

with American National Standard Institute and the Ameri-

can Society for Testing and Materials (ANSI/ASTM) stan-

dards. The solvent shall be free-owing and contain no

lumps, undissolved particles or any foreign matter that

adversely aects the joint strength or chemical resistance

of the cement. The cement shall show no gelation, strati-

cation, or separation that cannot be removed by stirring.

Refer to TABLE 5 for approved piping and tting materials.

CAUTION

Solvent cements for plastic pipe are ammable liquids

and should be kept away from all sources of ignition.

Do not use excessive amounts of solvent cement when

making joints. Good ventilation should be maintained to

reduce re hazard and to minimize breathing of solvent

vapors. Avoid contact of cement with skin and eyes.

Loading...

Loading...