Page 10

NOTE - When the furnace is installed on a platform in a

crawlspace, it must be elevated enough to avoid water

damage and to allow the evaporator coil to drain.

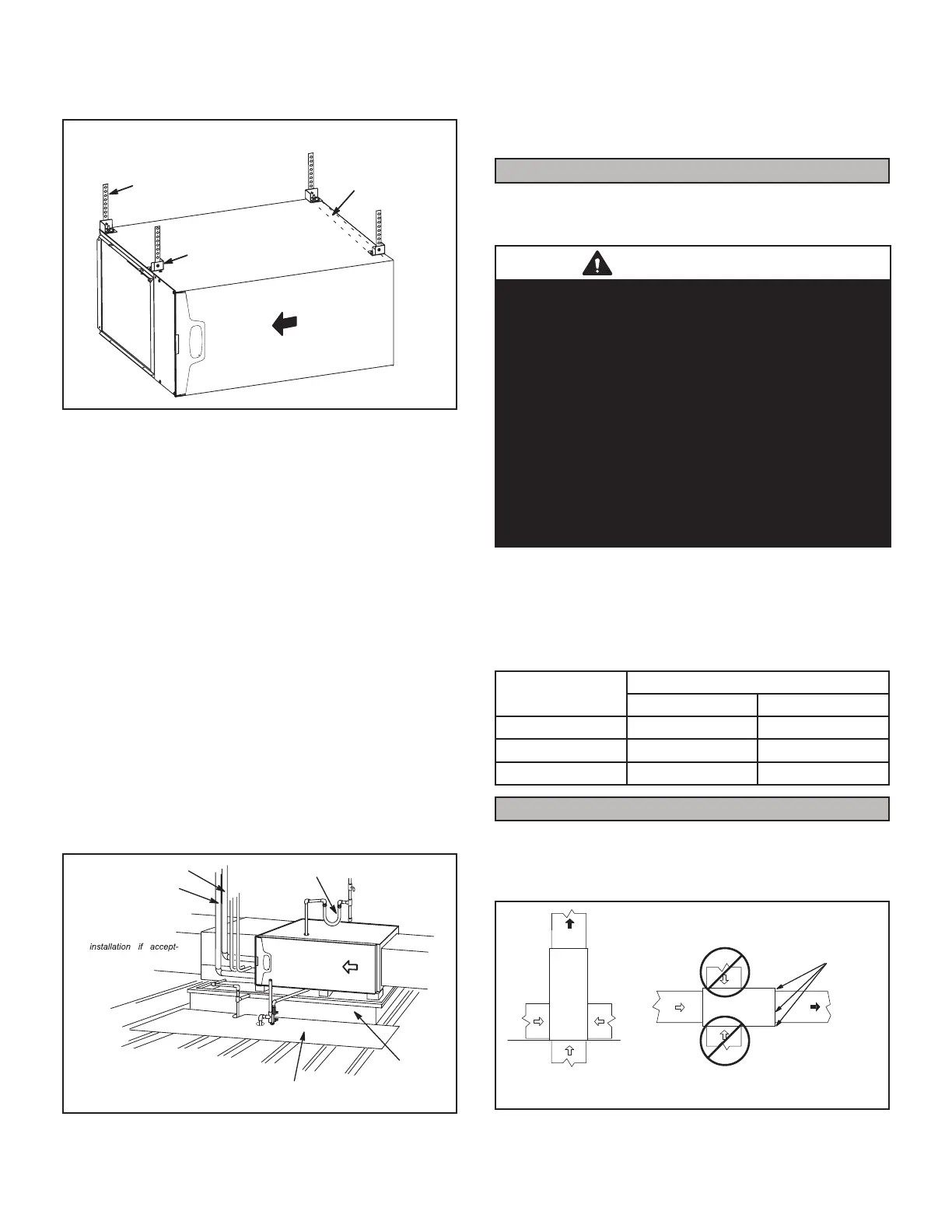

HORIZONTAL SUSPENSION KIT

Bracket

(typical)

Metal Strap

(typical)

Air

Flow

Internal Brace

(provided with kit)

FIGURE 12

Platform Installation of Horizontal Unit

1 - Select location for unit keeping in mind service and

other necessary clearances. See FIGURE 11.

2 - Construct a raised wooden frame and cover frame

with a plywood sheet. If unit is installed above

nished space, fabricate an auxiliary drain pan

to be installed under unit. Set unit in drain pan as

shown in FIGURE 13. Leave 8 inches for service

clearance below unit for condensate trap.

3 - Provide a service platform in front of unit. When

installing the unit in a crawl space, a proper support

platform may be created using cement blocks.

4 - Route auxiliary drain line so that water draining from

this outlet will be easily noticed by the homeowner.

5 - If necessary, run the condensate line into a

condensate pump to meet drain line slope

requirements. The pump must be rated for use

with condensing furnaces. Protect the condensate

discharge line from the pump to the outside to avoid

freezing.

6 - Continue with exhaust, condensate and intake

piping installation according to instructions.

*Gas connector may be

used for Canadian

able by local authority

having jurisdiction.

*GAS CONNECTION

RAISED

PLATFORM

SERVICE PLATFORM

INTAKE PIPE

EXHAUST PIPE

FIGURE 13

Return Air -- Horizontal Applications

Return air must be brought in through the end of a fur-

nace installed in the horizontal position. The furnace is

equipped with a removable bottom panel to facilitate in-

stallation. See FIGURE 7.

Filters

This unit is not equipped with a lter or rack. A eld-provid-

ed lter is required for the unit to operate properly. TABLE

1 lists recommended lter sizes.

IMPORTANT

If a higheciency lter is being installed as part of this

system to ensure better indoor air quality, the lter must

be properly sized. Higheciency lters have a higher

static pressure drop than standard eciency glass/foam

lters. If the pressure drop is too great, system capacity

and performance may be reduced. The pressure drop

may also cause the limit to trip more frequently during

the winter and the indoor coil to freeze in the summer,

resulting in an increase in the number of service calls.

Before using any lter with this system, check the

specications provided by the lter manufacturer against

the data given in the appropriate Lennox Product

Specications bulletin. Additional information is provided

in Service and Application Note ACC002 (August 2000).

A lter must be in place when the unit is operating.

NOTE - In upow applications where side return air lter is

installed on same side as the condensate trap, make sure

that clearance is maintained to ensure future access to

the lter access panel.

TABLE 1

Furnace

Cabinet Width

Filter Size

Side Return Bottom Return

17-1/2” 16 X 25 X 1 (1) 16 X 25 X 1 (1)

21” 16 X 25 X 1 (1) 20 X 25 X 1 (1)

24-1/2” 16 X 25 X 1 (2) 24 X 25 X 1 (1)

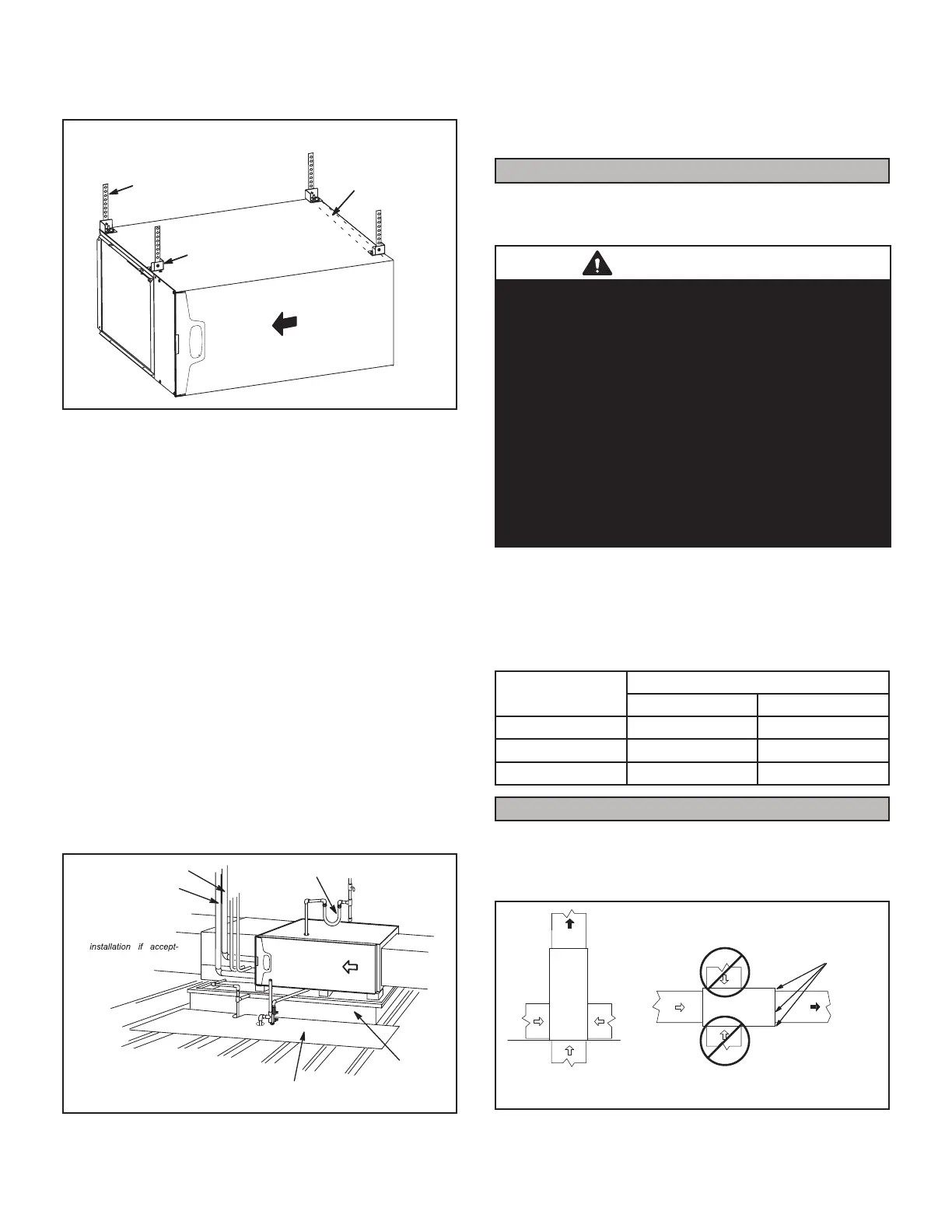

Duct System

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a qui-

et and low-static system that has uniform air distribution.

See below for proper duct installation.

FIGURE 14

HORIZONTAL UNIT

SUPPLY

AIR

SUPPLY

AIR

Install self tapping screws

to seal any potential air

leaks

UPFLOW UNIT

Loading...

Loading...