Page 60

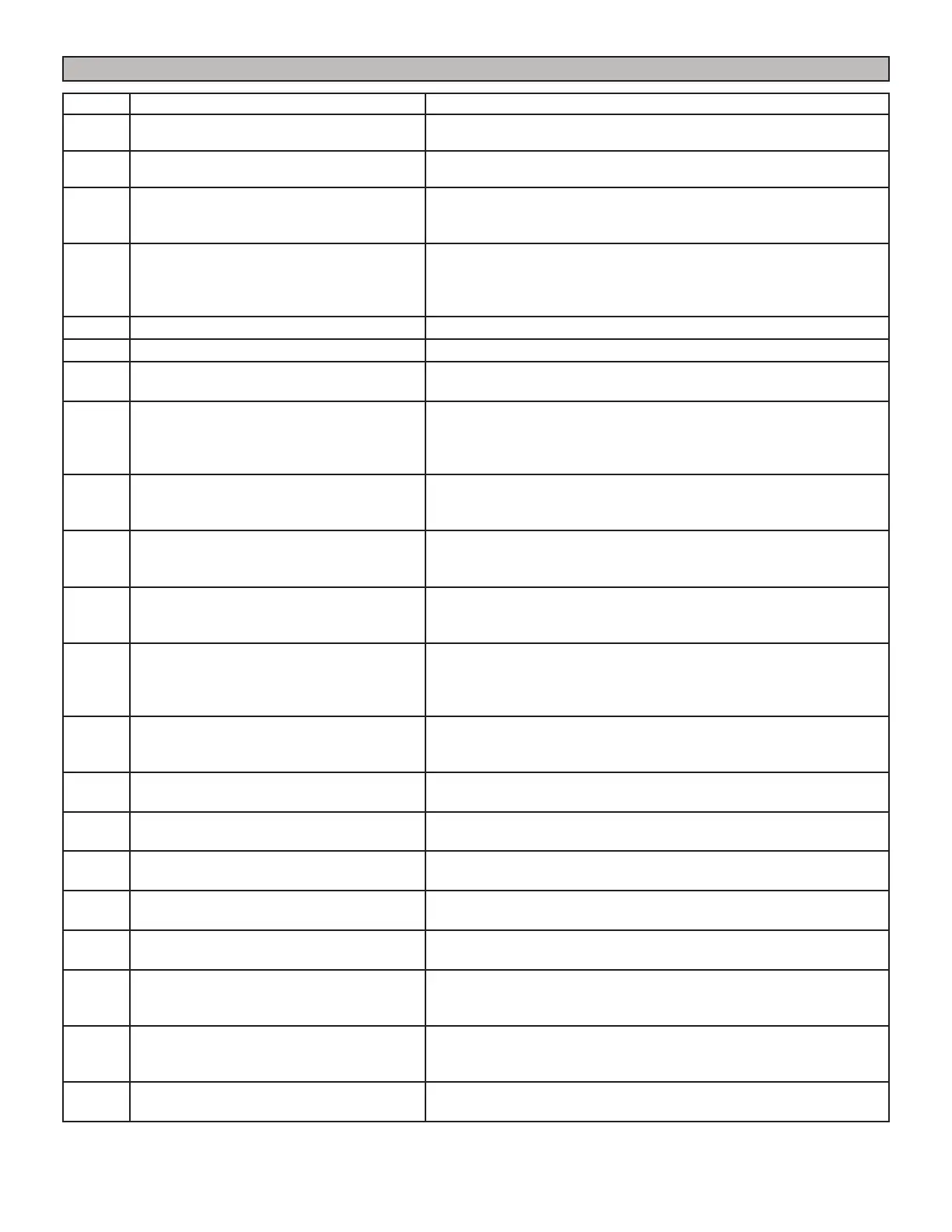

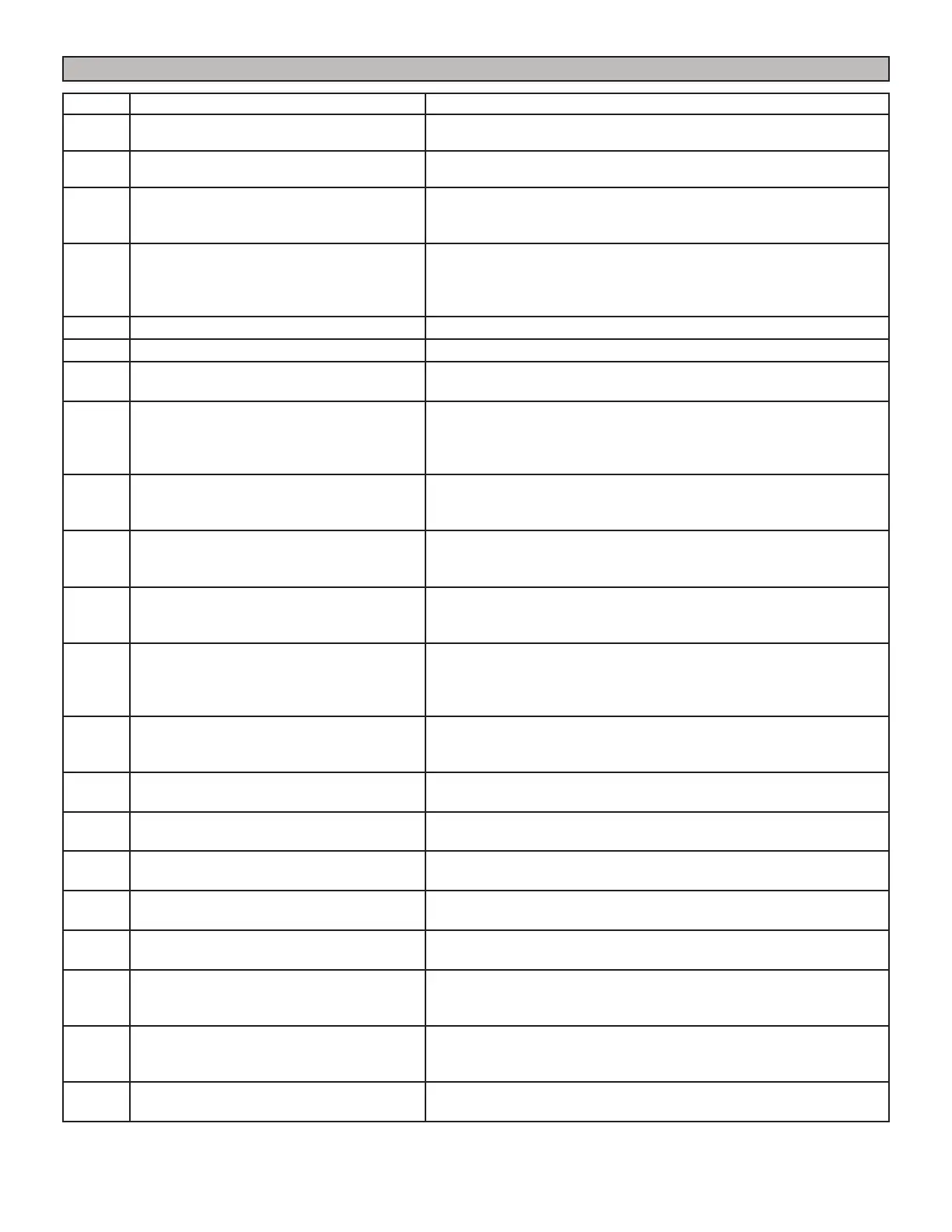

Integrated Control Diagnostic Codes

Code Diagnostic Codes/Status of Equipment Action Required to Clear and Recover

E200 Hard lockout - Rollout circuit open or previously

open.

Correct unit cause of rollout trip or replace ame rollout switch and test furnace

operation.

E201 Indoor blower communication failure - Unable to

communicate with blower motor.

Indoor blower communication failure including power outage.

E202

Indoor blower motor mis-match - Indoor

motor horsepower does not match unit

capacity.

Incorrect furnace size code selected. Check unit size codes on

conguration guide or in installation instructions.

E203

Appliance capacity / size is NOT

programmed. Invalid unit codes refer to

conguration ow chart in installation

instructions.

No furnace size code selected. Check unit size codes on conguration

guide or in installation instructions.

E204

Gas valve mis-wired. Check operation of gas valve.

E205

Gas valve control relay contact shorted. Check operation of gas valve.

E207

Hot surface ignitor sensed open - Refer to

troubleshooting in installation instruction.

Measure resistance of Hot Surface Ignitor, replace if open or not within

specication.

E223

Low pressure switch failed open - Refer to

troubleshooting in installation instruction.

Check inches of water column pressure during operation of low pressure

switch on heat call, measure inches of water column of operating

pressure, inspect vent and combustion air inducer for correct operation

and restriction.

E224

Low pressure switch failed closed - Refer to

troubleshooting in installation instruction.

Check low pressure switch for closed contacts, measure inches of water

column of operating pressure, inspect vent and combustion air inducer

for correct operation and restriction.

E225

High pressure switch failed open - Refer to

troubleshooting in installation instruction.

Check inches of water column pressure of high pressure switch on heat

call, measure inches of water column of operating pressure, inspect vent

and combustion air inducer for correct operation and restriction.

E226

High pressure switch failed closed - Refer to

troubleshooting in installation instruction.

Check high pressure switch for closed contacts, measure inches of

water column of operating pressure, inspect vent and combustion air

inducer for correct operation and restriction.

E227

Low pressure switch open during trial for

ignition or run mode. Refer to troubleshooting

in installation instruction.

Check inches of water column pressure during operation of low pressure

switch on heat call, measure inches of water column of operating

pressure, inspect vent and combustion air inducer for correct operation

and restriction.

E228

Unable to perform successful pressure switch

calibration.

Retry after 300 seconds. Error counter cleared when exiting lockout,

unable to perform pressure switch calibration. Check vent system and

pressure switch wiring connections.

E240

Low ame current - Run mode - Refer to

troubleshooting in installation instruction.

Check micro amperes of ame sensor, clean or replace sensor. Measure

voltage of neutral to ground for good unit ground.

E241

Flame sensed out of sequence - Flame still

present.

Shut o gas, check for gas valve leak.

E250

Limit switch circuit open - Refer to

troubleshooting in installation instruction.

Check why limit is tripping, overred, low air ow.

E252

Discharge air temperature too high (gas heat

only).

Check temperature rise, air ow and input rate.

E270

Soft lockout - Exceeded maximum number of

retries. No ame current sensed.

Check for gas ow, ignitor lighting burner, ame sensor current.

E271

Soft lockout - Exceeded maximum number of

retries. Last retry failed due to the pressure

switch opening.

See E 223.

E272

Soft lockout - Exceeded maximum number

of recycles. Last recycle due to the pressure

switch opening.

See E 223 and E 225.

E273

Soft lockout - Exceeded maximum number of

recycles. Last recycle due to ame failure.

See E 240.

Loading...

Loading...