Page 75

XP21

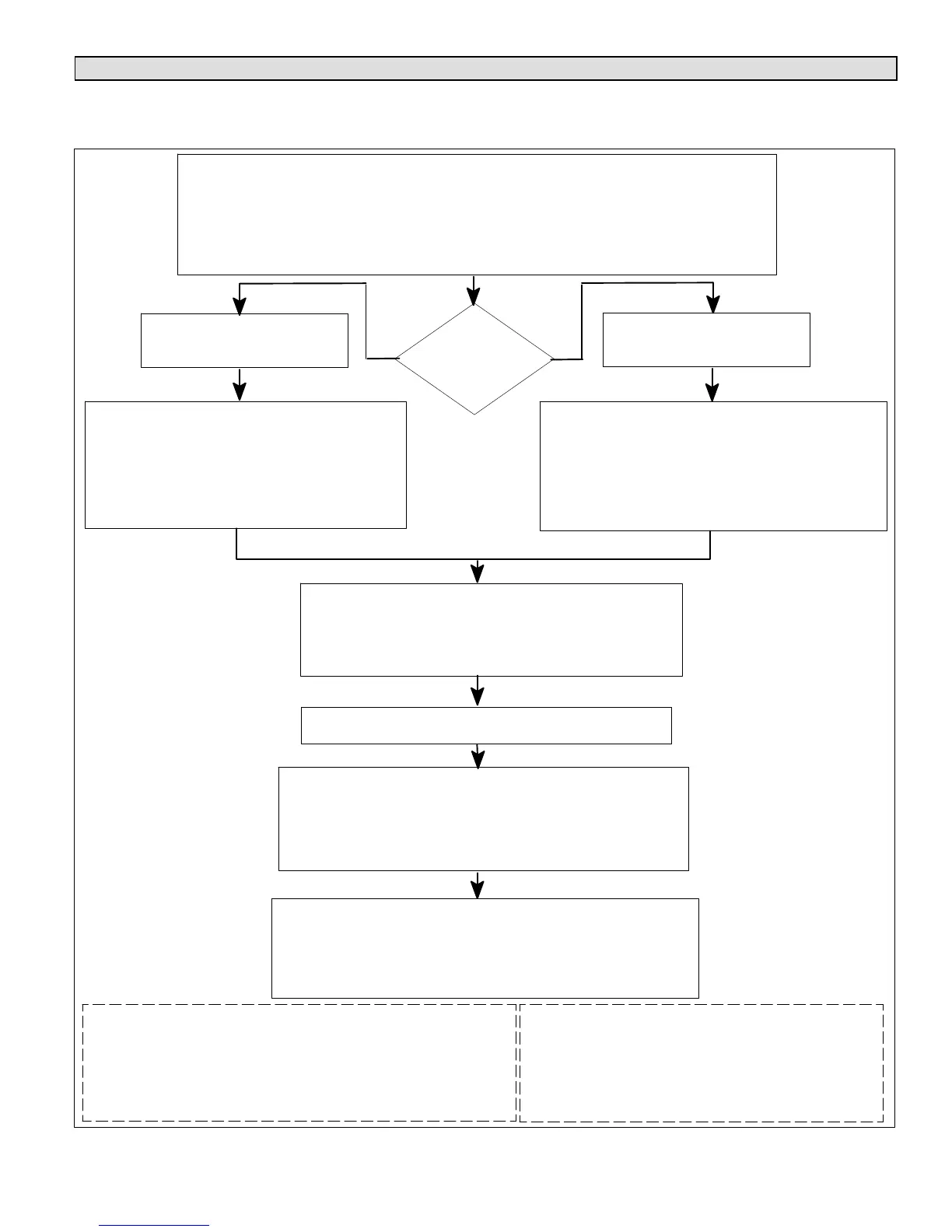

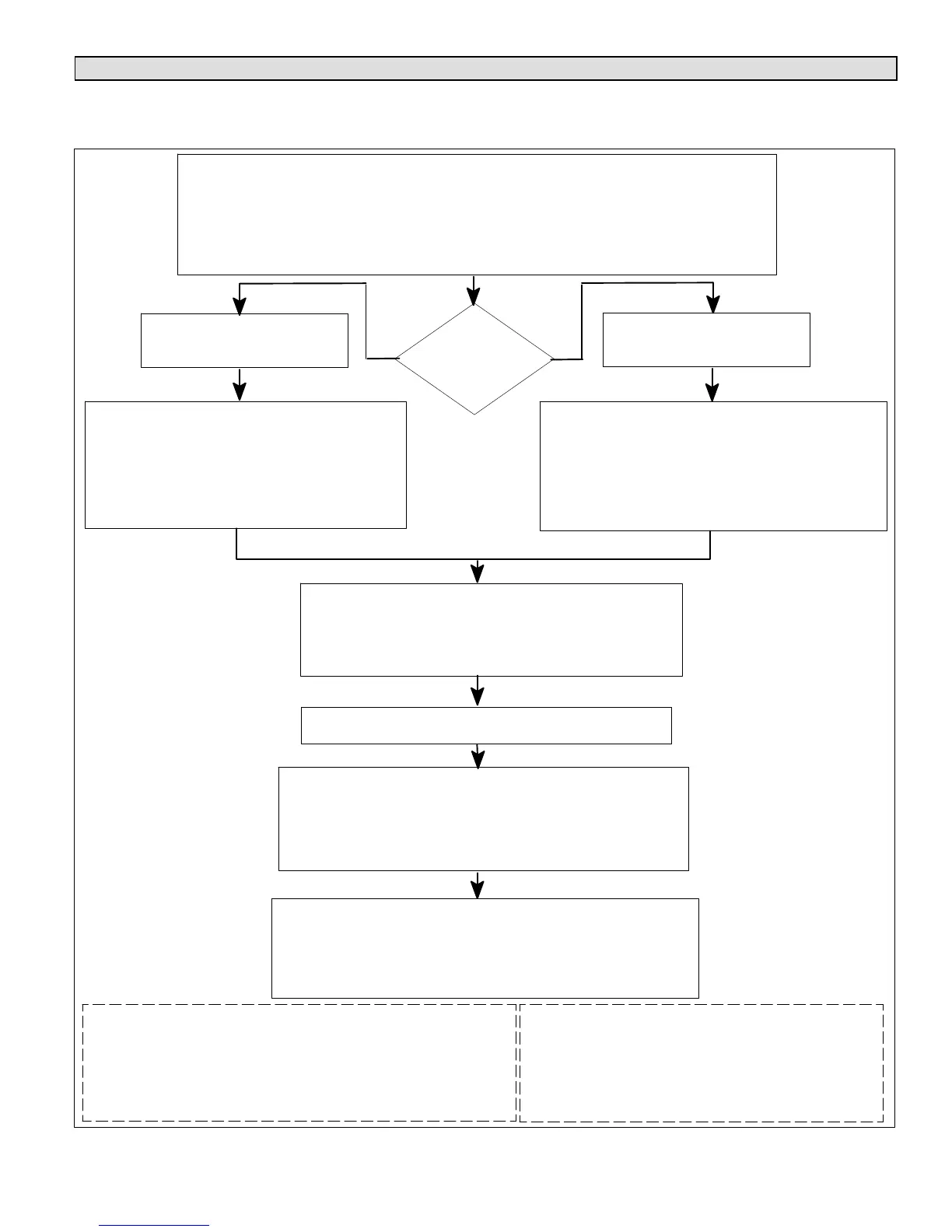

Unit Sequence of Operations

The following figures illustrated the overall unit sequence of operations along with various pressure switches and tempera-

ture sensor operations. The figures also illustration the use of the compressor anti−short cycle function in relations to unit

Status, Fault and Lockout LED Codes system operations interaction.

On 24VAC power−up or heat pump control (A175) reset, the heat pump control shall perform the

following tasks:

1. Start the anti−short cycle delay.

2. Check temperature sensor and pressure switches at the start of cooling demand.

3. Heat pump control responds to the thermostat input after the anti−short cycle timer expires. If there is

no thermostat input, control goes to standby mode.

Heat Pump control receives

cooling input.

The heat pump control (A175) will apply:

1. 24VAC to compressor contactor output Y1 OUT..

2. 24VAC to reversing valve output O terminal.

3. Output between 24 and 32 VDC on heat pump control’s

ECM fan terminals ECM Y1 FAN and ECM C.

NOTE − If low pressure switch is closed, system will ignore for

90 seconds.

The outdoor fan control (A177) will:

Receive the DC voltage signal from the outdoor control (A175) and

converted the signal to a pulse width modulation (PWM) signal. Jumper

settings will determine fan PWM OUT fan speed.

NOTE Refer to 17 for jumper settings.

1. For low (S87) and high (S4) pressure switches sequence of

operations, see figures 43 and 44.

2. For temperature switch RT28 sequence of operations, see

figure 45.

3. For Defrost calibration sequence of operations see figure 46.

4. For Defrost sequence of operations see figure 46.

Room thermostat calls for high (two−stage)

The heat pump control will apply::

1. 24VAC to second−stage solenoid output that will energized after the

first−stage compressor has been active for a minimum of five (5)

seconds.

2. Output between 24 and 32 VDC on heat pump control’s

second−stage ECM fan terminals ECM Y2 AND ECM C.

The outdoor fan control (A177) will:

Receive the DC voltage signal from the outdoor control (A175)

and converted the signal to a pulse width modulation (PWM)

signal. Jumper settings will determine fan PWM OUT fan speed.

NOTE Refer to table 17 for jumper settings.

Two−stage Ambient Lock−in Temperature

Should the ambient temperature be below the selected two−stage lock−in

temperature (jumper in place on jumper pin strip) , the two−stage solenoid

output will be energized after the one−stage minimum run timer expires

Energize two−stage ECM fan outputs ECM Y2 Fan and Y2 input/output.

Appropriate system status LED code is displayed to indicate two−stage heat

lock−in.

Room thermostat

calls for low (one−

stage)

Heat Pump control receives

heating input.

The heat pump control (A175) will apply:

1. 24VAC to compressor contactor output Y1 OUT..

2. Output between 24 and 32 VDC on heat pump

control’s ECM fan terminals ECM Y1 FAN and

ECM C.

NOTE − If low pressure switch is closed, system will

ignore for 90 seconds.

Figure 41. One− and Two−Stage Cooling Sequence of Operations (101796−XX Only)

Loading...

Loading...