22

• The seal on the unit refrigerant piping connec-

tions should remain in place until the last pos-

sible moment. This will prevent dust or water

from getting into the refrigerant piping before it

is connected.

• Flow the pipework with dry (oxygen-free) nitro-

gen (2.9 psig or 3 CFH) during brazing to avoid

oxidation which may block the refrigerant piping.

• Do not use ux when brazing copper-to-copper

piping. Use phosphor copper brazing ller alloy

(BCuP) which does not require ux. Flux has a

harmful eect on refrigerant pipe.

• Use a wet cloth to insulate the shut o valve dur-

ing brazing.

• Use dedicated gauges and hoses with R-410A

equipment.

Pressure Test

• Follow the pressure test specications in Table 2

for proper pressure testing procedures.

• Ensure the unit service valves are fully closed

and haven’t become loose during transportation.

• Use oxygen-free nitrogen to pressure test to 650

psig and hold for 1 hour.

Evacuate System

• Follow the Lennox pressure test specications

in table 1 and the triple evacuation process de-

scribed on this page to pressure test and evacu-

ate the system.

• Use a vacuum pump capable of evacuating to

lower than 500 Microns (0.5 Torr).

• Do not open any of the outdoor unit shut-o

valves (possible max 5 valves). The outdoor unit

does not need to be evacuated.

• Evacuate the system to 500 Microns (0.5 Torr), or

below, for 4 hours.

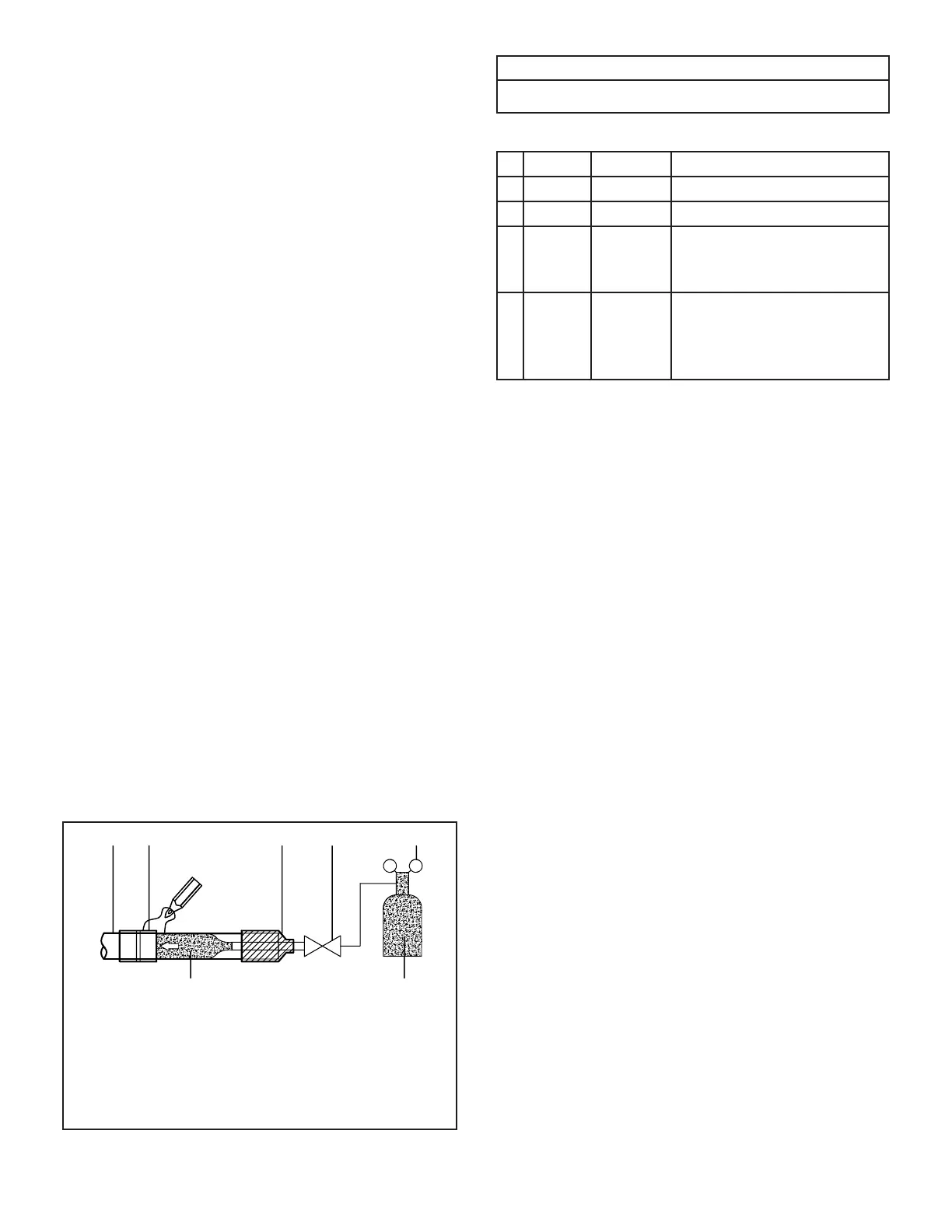

1 - Refrigerant pipe

2 - Part to be brazed

3 - Reducer

4 - Isolation valve

5 - Pressure-regulating valve

6 - Oxygen-free nitrogen

Figure 21. Brazing Best Practices

Table 2. Pressure Test Specications

1 3 bar 44 psig minimum of 10 minutes

2 15 bar 220 psig minimum of 10 minutes

3 32 bar 470 psig minimum of 10 minutes

4 45 bar 500 psig 1 hour. Stress test to

prove the integrity of the

complete installation.

5 32 bar 470 psig 24 hours. Lower system

pressure test, after

conrmation No. 4 was

successfully completed.

Triple Evacuation Procedure

A Micron or Torr gauge must be used for this

procedure.

1. Discharge the oxygen-free nitrogen and evacuate

the system to a reading of 8000 Microns (8 Torr)

using all service valves.

2. Break the vacuum by allowing nitrogen into the

three inter-connecting pipework port connections

(low pressure gas pipe, high pressure gas pipe

and liquid line pipe) until a positive pressure is

achieved.

3. Evacuate the system to a reading of 5000

Microns (5 Torr).

4. Break the vacuum by allowing nitrogen into the

three inter-connecting pipework port connections

(low pressure gas pipe, high pressure gas pipe

and liquid line pipe) until a positive pressure is

achieved

5. Evacuate the system to a minimum reading of

500 Microns (0.5 Torr).

6. For a moisture free system, ensure the vacuum

is held without movement for a minimum of 4

hours.

7. If pressure loss is detected, carry out steps 2

through 6 until no pressure loss is observed.

IMPORTANT!

Use only oxygen-free nitrogen (OFN).

Loading...

Loading...